Overview

Within This Page

The Warehouse space type is designed to store goods and materials, as well as to allow for the regular circulation of occupants, vehicles, and machinery that are typically associated with the handling of these goods and materials. Essential to this space type is the capacity to accommodate vertical storage, space for vehicle material movement, and anticipated high floor loads.

See also WBDG Warehouse Building Type.

Space Attributes

A wide range of storage alternatives, picking alternatives, material handling equipment and software exist to meet the physical and operational requirements of a warehouse space type, and proper integration of these features is essential. Warehouse spaces must also be flexible enough to adapt to future operations and storage needs. Typical features of Warehouse space types include the list of applicable design objectives elements as outlined below. For a complete list and definitions of the design objectives within the context of whole building design, click on the titles below.

Aesthetics

- Company/Organization Image: Provide an aesthetically pleasing work environment through the use of company symbols, logos, artwork, and other features that also make the work environment feel clean and safe.

- Sense of Place: Create a 'sense of place' so the warehouse has a unique character that engenders a sense of pride, purpose, and dedication for individual workers and the workplace community.

Accessible

- ADA Requirements: Warehouses must meet the requirements of the Americans with Disabilities Act (ADA) Standards. Provide accessible parking, entrances, aisles, and restrooms, etc.

- Access to Goods and Materials: Design the warehouse space with appropriate storage systems that allow ease of access by workers and equipment to goods and materials. Plan for appropriate systems to reach items at low and high levels within the space and goods and materials with different shelf lives.

Cost-Effective

When warehouse productivity and efficiency are increased, operational costs decrease. Incorporate these strategies to make the warehouse space more cost-effective.

- Visible Inventory: Ensure that the inventory is accessible and visible, allowing for ease of inventory and fulfillment to reduce costs.

- Storage Optimization: A fully optimized warehouse will improve traffic flow, reduce loss of stock, and boost productivity, all resulting in overall improved efficiency and reduced costs.

- Technologies: Incorporate warehouse management systems (WMS) to improve inventory management and visibility. Benchmarking can also be incorporated in order identify the key processes and ways to improve or refine them.

Functional / Operational

- Efficient Use of Space: Warehouse space types are often designed with higher bays to take advantage of vertical storage. Utilization of space is maximized while providing adequate circulation paths for personnel and material handling equipment such as forklift trucks.

- Design for Live Loads: Designs should anticipate the loads of stored materials and associated handling equipment, typically 250 LB/SF. Snow, wind, and seismic loads shall be considered where they are applicable. Racking in seismic areas must be built stronger and be better braced.

- Power and Utility Requirements: Differentiate between spaces that require power and utilities, and those that are for storage only. Depending on the goods being stored and handling equipment required, there may be a need for well-distributed power and utility lines throughout the space. Attempt energy efficient lighting when possible. Warehouse spaces typically include one floor drain for every two bays of storage, as well as sand and oil traps on waste lines.

- Energy-Efficient Lighting: Incorporate energy efficient lighting into all spaces.

- Proper Drainage: Warehouse spaces typically include one floor drain for every two bays of storage, as well as sand and oil traps on waste lines.

- Loading Dock: Warehouse space types are typically designed with one electro-hydraulic dock leveler per every five truck bays.

- Occupancy: Occupancy Group Classification is Storage Group S in Group S-1 or S-2 classifications with sprinklered construction. See also WBDG Secure/Safe—Fire Protection

Productive

- Personnel: Know the number of employees required, their current levels of training and shift timings, and other related factors to help design the warehouse layout in a way that does not limit the workforce's productivity. Also, the layout must be planned to safely accommodate new employees and future needs.

- Optimize the Warehouse Processes: Utilize planning and technology to optimize the warehouse processes of receiving, putaway, storage, picking, packing, and shipping. Optimizing these six processes will streamline the warehouse operations, reduce costs and errors, and achieve a higher level of efficiency.

Secure / Safe

- Life-Safety and Health Concerns: Address traditional life-safety and health concerns including measures to prevent occupational injuries and illnesses (work-related musculoskeletal disorders (WMSD), trips, falls, etc.), ensure electrical safety, and eliminate exposure to hazardous materials. The following operations have historically contributed to significant numbers of warehouse injuries and are considered to be the most hazardous: docks, powered industrial trucks, conveyors, materials storage, manual lifting/handling, roof ladders and hatches, and charging stations. Other serious operational safety problems include inadequate fire safety provisions, improper blocking of exits and egress paths, chemical exposure, improper use of lockout procedures, lack of ergonomics, and failure to wear personal protective equipment.

- Signage: Incorporate proper signage to clearly warn of hazards or to direct personnel to take precautions. The specific strategy for the warehouses signs must be determined early in the facility design process.

- Surfaces: Possess non-slip surface treatments on floors subject to wetting, such as outdoor docks, to eliminate slips and falls to personnel.

- Fire Safety: Design with fire sprinkler systems engineered to cover the specific commodity classification in the specific storage configuration for the planned warehouse. The adequacy of the sprinkler system must be evaluated when changes occur that can increase the hazard classification, such as introducing a new product line, using a different packaging material, or changing from wood pallets to plastic pallets.

- Security Systems: Include appropriate security systems in the overall warehouse design including physical access controls, cameras and sensors, cybersecurity measures, and also provide security training.

Sustainable

- Special HVAC: Provide proper ventilation under all circumstances. Plan for 100% exhaust from storage areas with paint, petroleum, aerosol, or other minor amounts posing moderate hazard storage conditions. Plan and provide for regular maintenance of the HVAC systems to improve efficiency and reduce maintenance and replacement costs. For more information, see High-Performance HVAC and Enhance Indoor Environmental Quality.

- Comfort: Use ceiling mounted fans to reduce heat stratification and provide air movement, thus increasing worker comfort in both summer and winter. Mount fans above highest forklift level for worker safety.

- Energy Efficiency: Include energy-efficient fixtures, windows, systems, and appliances, e.g., motion sensor instant-on lighting systems, wherever feasible.

- Insulation: Incorporate wall and roof insulation that meet codes and guidelines for the particular climate zone and operating conditions to achieve maximum temperature regulation and occupant comfort.

- Water Efficiency: Incorporate water saving fixtures and equipment to protect and conserve water.

Considered to be the world's most sustainable logistics warehouse, this project incorporates building materials which reduce pollutants to air, water, and soil. Healthy, safe materials were specified to enhance the comfort and well-being of all building users. Sensors and smart meters monitor air and water quality, internal noise, lighting, humidity and temperature, occupancy, and occupancy patterns. Optimal thermal comfort maximizes productivity. Photo Credit: Chetwoods

Example Program

The following building program is representative of Warehouse space types.

WAREHOUSE

| Description Tenant Assignable Spaces |

Qty. | SF Each | Space Req'd. | Sum Actual SF | Tenant Usable Factor | Tenant USF |

|---|---|---|---|---|---|---|

| Office Spaces | 350 | |||||

| Front Office | ||||||

| Clerical | 1 | 80 | 80 | |||

| General Manager | 1 | 180 | 180 | |||

| Supervisor | 1 | 120 | 120 | |||

| Office Support Spaces | 80 | |||||

| Support/File Room | 1 | 80 | 80 | |||

| Tenant (subtotal) | 430 | 1.34 | 575 | |||

| Receiving And Shipping | 4,100 | 1.09 | 4,481 | |||

| Docks | 4 | 400 | 1,600 | |||

| Staging | 1 | 2,500 | 2,500 | |||

| Warehouse | 35,600 | 1.05 | 37,536 | |||

| Package Disassembly | 1 | 1,500 | 1,500 | |||

| Package Assembly | 1 | 1,500 | 1,500 | |||

| Rack Storage | 1 | 20,800 | 20,800 | |||

| Controlled Storage | 2 | 1,600 | 1,600 | |||

| Bulk Storage | 1 | 6,000 | 6,000 | |||

| Inventory Control | 2 | 120 | 240 | |||

| Dispatcher | 1 | 120 | 120 | |||

| Forklift Parking | 20 | 112 | 2,240 | |||

| Tenant Suite | 40,130 | 1.06 | 42,592 | |||

| Tenant Usable Areas | 42,592 |

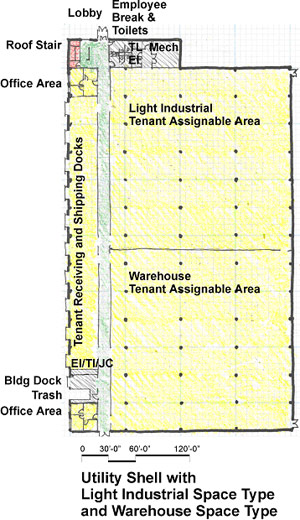

Example Plans

The following diagram is representative of typical tenant plans.

Example Construction Criteria

For GSA, the unit costs for Warehouse space types are based on the construction quality and design features in the following tableDownload gsa_constr_criteria_warehouse.pdf . This information is based on GSA's benchmark interpretation and could be different for other owners.

Relevant Codes and Standards

Warehouses must be designed to meet all local building, fire, and life-safety codes. When in doubt, consult with the local building official. The Occupational Safety and Health Administration (OSHA) also provides guidance for warehouse safety.

- Occupational Safety and Health Act of 1970 (29 U.S.C. § 651 et seq.)

- 29 C.F.R. Part 1903.1 et seq.—Inspections, Citations, and Proposed Penalties of Occupational Safety and Health Act of 1970

The following agencies and organizations have developed codes and standards affecting the design of Warehouse space types. Note that the codes and standards are minimum requirements. Architects, engineers, and consultants should consider exceeding the applicable requirements whenever possible.

- Department of Defense (DOD)

- National Fire Protection Association

- U.S. Access Board

- U.S. General Services Administration

Additional Resources

Organizations

- American Society of Safety Professionals (ASSP)

- Council of Supply Chain Management Professionals (CSCMP)

- Institute of Industrial & Systems Engineers (IISE)

- International Association of Refrigerated Warehouses (IARW)

- International Warehouse Logistics Association (IWLA)

- Occupational Safety and Health Administration (OSHA)

- The International Society of Logistics (SOLE)

- Warehousing Education and Research Council (WERC)

Publications

- Architectural Graphic Standards, 12th Edition by The American Institute of Architects, Dennis J. Hall. New York, NY: John Wiley & Sons, Inc., 2016.

- "Guide to Sizing Warehouse Aisles for Various Types of Lift Trucks" by Edward Brown. WarehouseIQ.com, October 8, 2011.

- Rules of Thumb: Warehousing and Distribution Guidelines, 11th edition by TranSystems, 2010.

- The Time, Space & Cost Guide to Better Warehouse Design, Second Edition by Maida Napolitano and Gross & Associates. August 24, 2017.

- Warehouse Safety: A Practical Guide to Preventing Warehouse Incidents and Injuries by George Swartz. 1999. ISBN: 0865876479

- Warehousing Profitably, Third Edition by Kenneth Ackerman. The Distribution Group, 2011.

Websites

Others

- Building Research Information Knowledgebase (BRIK)—an interactive portal offering online access to peer-reviewed research projects and case studies in all facets of building, from predesign, design, and construction through occupancy and reuse.