by Joseph C. Dean, P.E. for the Director, Corrosion Policy & Oversight (DCPO) [(OASD) [Materiel Readiness]]

Updated: 09-30-2021

Introduction

Within This Page

Corrosion is defined as the deterioration of a material or its properties due to a reaction of that material with its chemical environment (10 U.S.C. § 2228). It is inclusive of "rust" and the oxidation of other metals and the deterioration of all materials, which can be caused through sun exposure, mold and mildew, wind, and other environmental elements.

The CPC Source WBDG Pages provide an extensive CPC resource. These webpages are intended to provide just-in-time information for facilities professionals to assist in the inclusion of CPC processes and materials into the appropriate phases of the FLC. The CPC Source topics include knowledge and training linked to the vast Whole Building Design Guide (WBDG) resources. By researching and leveraging the content on the CPC Source, planners, engineers, architects, designers, sustainment professionals, and contractors will be able to make informed decisions resulting in improved facility durability and longevity.

Description

Corrosion Overview

The Department of Defense (DoD) acquires, operates, and maintains a vast array of physical assets that include buildings, wharves, airfields, pavements, and other facility categories. All these assets are susceptible to corrosion. Corrosion can be extensive and costly. The CPC Source provides information on planning, design, sustainment, and workforce competencies, as well as corrosion science, paints, coatings, environmental severity classifications (ESC), and cathodic protection. The Knowledge Pages provide specific facility category CPC information.

Facility vulnerability and the potential effects of corrosion should be fully evaluated and addressed throughout the FLC. By learning more about the impacts of corrosion, informed decision-making can increase durability and decrease sustainment costs. The CPC Competencies and Training pages provide additional information and resources to improve facilities professionals' knowledge development.

Facilities Guidance and Policy Overview

The DoD has in place extensive policy and guidance to facilitate effective management of corrosion in the facilities that are required to support the national defense. The Policy Table provides insights into DoD Guidance and Policy as it relates to CPC. The Joint Staff and each Military Service have issued, in varying degrees, their own implementing guidance and policies related to CPC.

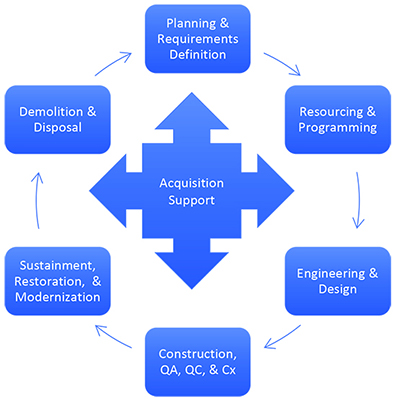

The Facilities Life Cycle

The FLC (see Figure 1) involves elements of Planning and Requirements Definition, Resourcing and Programming, Engineering and Design, Construction, Quality Control (QC), Quality Assurance (QA), and Commissioning (Cx), Sustainment, Restoration, and Modernization (SRM), and Demolition and Disposal. The CPC Source Acquisition Issues page elaborates upon the interaction of the Acquisition System with the FLC. Focusing on CPC throughout the FLC will ensure that durability is increased while operational needs and design service life are met.

Figure 1: The Facilities Life Cycle

Source: DCPO

Planning and Requirements Definition

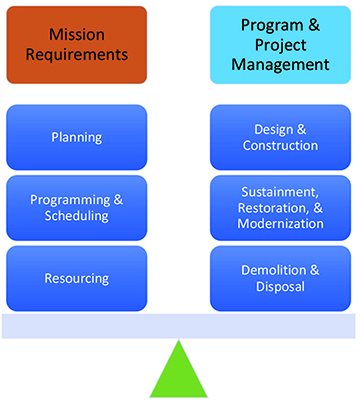

Facilities readiness and availability impacts weapons systems sustainment, training, and operations. To ensure desired level of functionality, facilities must be planned, constructed, and sustained in sync with the requirement. The applicable ESC for that location (see UFC 1-200-01, Tables A-1 and A-2) must be considered when planning a facility. Striking the balance between all of the FLC stages (see Figure 2) while incorporating CPC requirements is essential. Planners should consider CPC issues for all facilities, regardless of location or mission. It is critical to include CPC considerations for a specific facility or group of facilities to be constructed in high corrosion areas (Zones 4 and 5) such as Guam or waterfront locations in planning documents.

Decisions and plans to address corrosion may occur later in one of the steps in the facilities life cycle process. Delaying CPC considerations and actions will negatively affect the durability of the facility over the life cycle, especially if it is not resourced. The CPC Source Importance of Including Corrosion in the Planning Process page provides greater insights into the inclusion of CPC in facilities planning.

Figure 2: Balancing Facilities Life Cycle Realities

Source: DCPO

Resourcing And Programming

Depending on the type of project (Military Construction, SRM) the actual process of planning and funding will vary. It is important to understand the resourcing processes to ensure that funds are available in a timely manner. Each component and DoD have issued project submission and resourcing guidance. Ensuring that CPC is included in project documentation and is properly resourced requires that the planners understand CPC, the corrosion requirement and the associated urgency. The CPC Source Planning Page provides additional insights and knowledge development is addressed in in the Facilities Corrosion Knowledge Track Summary (Tracks 1 and 4).

Engineering And Design

CPC-related engineering and design includes corrosion problem-solving, developing the Request for Proposal (RFP), selecting criteria, and developing plans and specifications. UFC 1-200-01 Corrosion Prevention and Control Chapter provides the general design requirements for CPC such as:

- ESC for each installation

- Requirements for corrosion-prone locations

- System, component, and material design requirements

More severe ESC locations, corrosion prone locations, and areas of high humidity require enhanced solutions found in the corresponding Unified Facilities Guide Specifications (UFGS). All of the above factors when employed correctly in design will help prevent or mitigate corrosion, improve sustainability and durability, meet design service life requirements, and reduce cost over the facilities' life cycle.

Corrosion problem solving may require engineering analysis, and, in some cases, assistance from corrosion and coating subject matter experts. The CPC Source provides insights into several technical areas to assist with corrosion problem solving. Determination of corrective measures depends heavily on understanding the specific materials involved. For example, the selection of coatings in humid locations or in the splash zone along a waterfront that will inhibit corrosion and extend the FLC, and ultra-violet (UV) radiation and temperature ages and stiffens the binder in asphalt concrete pavements which leads to cracking, structural issues, and ultimately failure. Cathodic protection (CP) systems are required for certain facilities such as natural-gas distribution and storage tanks. Including the CP system when needed ensures system safety and a longer life cycle.

The following CPC Source pages are available to assist the engineers, architects, designers, and sustainers:

- CPC Source Acquisition Issues

- CPC Source Criteria

- CPC Source Design and Construction Issues

- CPC Source Competencies

- Knowledge Areas

- Facilities Corrosion Knowledge Track Summary (Tracks 1, 2, and 4)

- DoD Corrosion Training Courses

- Environmental Severity Classification (ESC)

- DoD Unified Facilities Criteria

Good corrosion performance is both an attribute of an entire facility and the sum of its sub-components which includes leveraging best practices, which are often based on local lessons learned. The Facilities and Infrastructure Corrosion Evaluation (FICE) Study submitted to the U. S. Congress in July 2013, surveyed 30 installations and assessed the effectiveness of the CPC programs at those locations. The FICE Study provided insights into a broad list of topics that included Policy and Guidance, Environmental Severity Impacts, Sustainment, Maintenance Management, Best Practices, and Training. Examples of the major types of corrosion to be considered are discussed in the Corrosion Science Knowledge Page. The Facilities Corrosion Impacts on Operations and Mission Table provides insights into facilities traditionally impacted by corrosion.

An excellent example of leveraging criteria and design guidance is in the high-risk CPC area in Guam and the Marianas Islands where this knowledge assists with providing more sustainable and durable facilities and in the reduction of life-cycle costs. The Marianas Navy and Marine Corps Design and Construction Standards (MDACS) (September 2017), leverages the WBDG.org and guides engineers and architects in selecting the right criteria and materials for sustainability and durability in that highly corrosive environment. The Design and Construction page discusses design best practice decisions in the new Guam Navy Hospital (Photo 1) that was completed in April 2014 and was summarized in Chapter 4 of the FICE Study.

Photo 1: Guam Naval Hospital under construction utilizing CPC best practices

Source: DCPO

Construction, Quality Assurance (QA), Quality Control (QC), And Commissioning (Cx)

CPC requirements should be included in the contract project, construction documentation and the Contractor's QC and Cx Plans regardless of the size and type of procurement. The Government's QA Plan should be detailed enough to include contract CPC requirements. Both the Government and Contractor should ensure that engineers, architects, and construction personnel are well versed in CPC (see the CPC Source for assistance). Poor construction practices can easily negate the best design that is intended to produce a durable and corrosion-resistant structure. For specific insights see the CPC Source Design and Construction Issues and Acquisition Issues Pages.

Photo 2: AFJAGS expansion construction

Source: William Birchfield, Air University Public Affairs

Commissioning is addressed in other sections of WBDG.org and in the Building Information Management (BIM) content area. During turnover from the construction agent to the installation responsible for sustainment, key documents that include information on the constructed facility including as-built drawings, coatings, cathodic protection systems, equipment descriptions, operations, manuals, and warranties, along with commissioning information must be transferred to the Sustainment Restoration and Modernization (SRM) manager. This is typically referred to as Electronic Operations and Maintenance Support Information (eOMSI) "eOMSI" (UFGS 01 78 24.00 20), and is primarily and electronic series of files. This information is key to successful SRM management, durability and life cycle expectations.

Sustainment, Restoration And Modernization (SRM)

Sustainment includes the maintenance and repair activities necessary to ensure that facilities are available to meet mission and operational requirements. It also includes routine maintenance, major repairs, and replacement of facility components that occur periodically throughout the life cycle of facilities. Pursuing timely corrective action reduces corrosion damage, system failure, and increases facilities readiness. Facilities managers must always decide which requirement to address while deferring others in the face of limited resources and competing priorities.

Photo 3: Building Renovations, 149th Fighter Wing Civil Engineers

Source: MSGT. Mindy Bloem

From a corrosion perspective, materials typically degrade at a higher rate once rust forms and chemical deterioration of the material begins. Creating and executing SRM plans that are leveraged with a thorough knowledge of as-built conditions will ensure life-cycle expectations. CPC preventive maintenance is usually more cost effective than corrective maintenance. Performing facility inspections involves identification, recording and assessing corrosion. Corrosion deficiency evaluation requires determination of local ESC Zones, type and extent of corrosion, component age, and type of material and specific corrosion present. Follow-up actions include determining the scope of the repair, identifying funding, creating a design, issuing a contract and returning the facility to functional levels. Delaying action on correction of the corrosion deficiency may result in emergency repair actions. Ignoring the problem will result in downtime and lost productivity, ultimately costing more in resources, and reduction on facility readiness. Additional resources are available at:

- CPC Source SRM

- CPC Source Competencies

- Knowledge Areas

- Facilities Corrosion Knowledge Track Summary (Tracks 1, 2, and 4)

- DoD Corrosion Training Courses

Demolition And Disposal

SRM decisions often require an evaluation to determine the extent of renovation and restoration of existing facilities to extend life of the facility to meet mission needs. If a replacement facility is programmed, part of that project may include removal of the existing facilities. Disposal of existing facilities that are no longer serviceable may be scheduled for demolition and removal (see Photo 4). Corrosion deterioration can accelerate the demolition decision. Much of the demolition and removal process is guided by environmental requirements and compliance actions. If life-cycle extension in the form of renovation or restoration is determined to be feasible, then the CPC information provided in the previous sections can assist in designing and constructing the facility modifications.

Photo 4: Steam Plant Demolition, Marine Corps Installations East

Source: LCPL Christian Ayers

Acquisition Strategies And Support

Differing acquisition strategies and delivery methods such as Design/Bid/Build (DBB), Design-Build (DB), Simplified Acquisition, and Task Order/Indefinite Quantity Job Order Contracts are selected consistent with Component policy and the Federal Acquisition Regulations. CPC should be included in the requirements definition, technical selection factors, RFP and execution process. For a more complete explanation see the CPC Source Acquisition Issues Page. CPC Acquisition workforce competency recommendations can be found in the Facilities Corrosion Knowledge Track Summary Table (Track 7).

Summary

Application of good CPC applied in the appropriate phases of the FLC (see CPC Checklists Tool: Corrosion Prevention and Control (CPC) Checklist Organized by Facility Life Cycle Steps (1)) is essential to prolonged sustainability, durability, reduced life-cycle costs, and improved facilities readiness. There are extensive resources in the form of criteria, materials, and technology to help engineers, designers, sustainment professionals, and constructors achieve successful CPC. Whether the design or sustainment issue is selection of advanced coatings, or in determining the appropriate cathodic protection system, the WBDG and CPC Source provides insights and direction into making the correct decision.

The List of Corrosion-Related D, CPO-Funded Projects provides an overview of CPC related research, many of which are either transitioning into or have transitioned into criteria. The CPC Source contains expanded resources, guidance, criteria, processes, best practices, new technologies, and lessons learned.

Additional Resources

Criteria on the WBDG are generally based on industry standards. An industry standard is an established norm or requirement about technical systems, usually presented in the form of a formal document. It establishes uniform engineering or technical criteria, methods, processes and practices. Industry Standards can also be found in the form of reference specifications. The standards referenced in criteria are usually written and maintained by standards organizations.

- Federal Facility Criteria–Extensive electronic library of construction guide specifications, manuals, standards and many other essential criteria documents

- Unified Facilities Criteria–Master list of UFCs

- Unified Facilities Guide Specifications–Master list of UFGSs

- FICE Study

- Policy Table

- Unified Master Reference List (UMRL)–Lists publications and industry criteria referenced in UFGSs

- CPC Source Criteria

Criteria Guidance

- DoDD 4270.5, Military Construction —Provides guidance on MILCON program management. Establishes requirement that UFCs and UFGSs must be used to the greatest extent possible for planning, design, and construction (restoration or modernization) of facilities, regardless of funding source.

- UFC 1-200-01, DoD Building Code (General Building Requirements) Represents the foundational document of the UFC program in providing general building requirements and overarching criteria, establishing the use of consensus building codes and standards, establishing criteria implementation rules and protocols (including core UFC), and identifying unique military criteria. In accordance with the authority in MIL-STD-3007, UFC are prepared by DoD committees called Discipline Working Group (DWG), and are approved by the Military Services under the authority of the Engineering Senior Executive Panel (ESEP).

For service and agency-specific mandates, please refer to their associated policy and guidance.

- Office of the Deputy Assistant Secretary of Defense for Construction

- US Army Corps of Engineers

- Engineer Research and Development Center, Construction Engineering Research Laboratory (ERDC-CERL)

- Air Force Civil Engineer Center (AFCEC)

- Naval Facilities Engineering Command

- Naval Facilities Engineering and Expeditionary Warfare Center (NAVFAC EXWC)

- USMC HQ Installations & Logistics

WBDG

Design Objectives

- Cost-Effective

- Utilize Cost and Value Engineering Throughout the Project Life Cycle

- Historic Preservation

- Sustainable

Design Disciplines

- Applicable to Design Disciplines

Guides & Specifications

Unified Facilities Criteria (UFC)

- Unified Facilities Criteria (UFC) List

- UFC 1-200-01 DoD Building Code (General Building Requirements)

- UFC 1-300-02 Unified Facilities Guide Specifications (UFGS) Format Standard

- UFC 2-000-05N Facility Planning Criteria for Navy/Marine Corps Shore Installations

- UFC 2-100-01 Installation Master Planning

Unified Facilities Guide Specifications (UFGS)

- Unified Facilities Guide Specifications List

- UFGS 01 78 24.00 20 Facility Electronic Operation and Maintenance Support Information (eOMSI)

- UFGS 02 41 00 Demolition and Deconstruction

Organizations

- American Concrete Institute (ACI)

- American Institute of Steel Construction (AISC)

- American Institute of Timber Construction

- American Public Works Association (APWA)

- American Society for Testing and Materials (ASTM)

- American Society of Civil Engineers (ASCE)

- American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE)

- APPA

- Asphalt Institute

- Defense Acquisition University

- IEEE

- International Facility Management Association

- The Association for Materials Protection and Performance (AMPP)

- The American Society of Mechanical Engineers

Publications

- Facilities and Infrastructure Corrosion Evaluation (FICE) Study (July 2013)

- DoD 7000.14-R (Multiple Volumes 1 thru 16) DoD Financial Management Guidebook USD (Comp)

- CPC Source Criteria

- Corrosion Prevention and Control (CPC) Source

- Marianas Navy and Marine Corps Design and Construction Standards (MDACS)

- NAVFAC Design-Build Master RFP

- Comprehensive Facility Operation and Maintenance Manual

- Public Works Technical Bulletin 200-1-146 30 June 2015

- Unified Master Reference List (UMRL)

- CPC Source—Environmental Severity Classification (ESC)

- Corrosion Toolbox

- Corrosion Prevention and Control Checklists Tool