Overview

Within This Page

Light Industrial space types are used for the assembly, disassembly, fabricating, finishing, manufacturing, packaging, and repairing or processing of various types of materials. Light Industrial space types can include but are not limited to spaces for printing, commercial laundry, film processing, vehicle repair garages, building maintenance shops, metal work, millwork, and cabinetry work.

See also Warehouse building type and Warehouse space type.

Printing press

Space Attributes

Light Industrial space types must be designed to accommodate a structured working environment with a heavy reliance on machinery and technology. Well laid out circulation spaces are crucial to the safety and well-being of building occupants, and will also increase productivity. The model for light industrial buildings is changing due to the increased demand for goods and the consumer or client calling for faster production and delivery rates. So the spaces need to accommodate these changes. Inventory space in light industrial facilities has grown vertical due to land becoming more expensive and less available. Designing vertically increases the useable space without increasing the physical footprint.

Typical features of Light Industrial space types include the list of applicable design objectives elements as outlined below. For a complete list and definitions of the design objectives within the context of whole building design, click on the titles below.

Accessible

-

Accessible Elements: Industrial spaces should be accessible to serve employees and clients. This includes providing accessible entrances, bathrooms, and spaces around equipment. The entrance into the space should have an opening of at least 32 inches, include an accessible threshold, and door opening force that meets requirements. The door equipment should be operable with one hand and not require tight grasping, pinching, or twisting of the wrist.

- Universal Design: Design spaces and elements with universal design in mind in order to serve everyone.

Functional / Operational

-

Account for Functional Needs: Light Industrial space types are often designed with higher bays to take advantage of vertical storage. Utilization of space is maximized while providing adequate circulation paths for personnel and machinery.

-

Design for Live Loads: Designs should anticipate the loads of stored materials and associated handling equipment, typically 250 LB/SF. Snow, wind, and seismic loads shall be considered where they are applicable. Racking in seismic areas must be built stronger and be better braced.

-

Power and Utility Requirements: While general assumptions about power and utility needs can be made, specific machinery and industrial practices will mandate certain essential steps. Typical electrical requirements for the Light Industrial space types include high voltage service to every shop area and a dedicated circuit for every machine station at 250 SF per machine station. Light Industrial space types typically include one floor drain for every two building bays, as well as sand and oil traps on waste lines.

-

Loading Dock: Light Industrial space types are typically designed with one electro-hydraulic dock leveler per every five truck bays.

- Occupancy: Occupancy Group Classification is Factory Industrial Group F-1, Moderate Hazard with sprinklered construction. See also WBDG Secure/Safe—Fire Protection

Productive

-

Integrate Technological Tools: Stay current and integrate technology in the space to ensure a productive work flow.

-

Assure Reliable Systems and Spaces: The success of the business or service performed in the space will be dependent upon the reliability of the equipment and technology used to perform the tasks. Perform regular maintenance on all systems and equipment in order to provide reliability.

- Provide Comfortable Environments: Provide spaces that support the individual as well as the team and organization, which also allow and encourage collaboration with other organizations or groups. Ensure that the thermal, visual, and acoustic comfort are addressed in the space.

Sustainable

-

Special HVAC: Provide proper ventilation under all circumstances. Plan for 100% exhaust from storage areas with paint, petroleum, aerosol, or other minor amounts posing moderate hazard storage conditions. Provide carbon monoxide detectors in areas where combustion engines may be present, and combustible gas detection in areas where fuels and combustible gases may be present. Both of these detection systems should be connected to the alarm and exhaust ventilation system.

-

Daylight: Provide as much natural daylight as possible to improve employee productivity as well as reduce the need for electric lighting sources. This can be achieved through the proper placement and balance of windows and skylights.

-

Energy Efficiency: Incorporate energy efficient lighting, fixtures, and equipment throughout the space. Develop a plan to reduce energy loads by turning off equipment when not in use and incorporating lighting controls, motion detectors, and smart building technologies.

- For more information, see WBDG Sustainable—Enhance Indoor Environmental Quality.

Secure / Safe

-

Hazardous Material Handling: As the storage and handling of hazardous materials may be a common daily activity in the Light Industrial space type, designs must include areas within the space that can accommodate such materials safely.

-

Information Security: Provide appropriate security measures to protect data and programs that relate to the processes performed in the space. Plan for network security, including where data is stored, and critical functions that must be performed even in the midst of a manmade or natural disaster.

- Plan for Natural and Manmade Hazards: The space should be able to respond resiliently to hazards or disasters. Develop a plan to keep operations running smoothly in the event of a disaster. Locate and identify appropriate areas for egress in the event of an emergency.

This loading dock incorporates a safety gate which reduces the danger of falls from docks, bays, or exposed edges when closed.

Example Program

The following building program is representative of Light Industrial space types.

LIGHT INDUSTRIAL

| Description Tenant Assignable Spaces |

Qty. | SF Each | Space Req'd. | Sum Actual SF | Tenant Usable Factor | Tenant USF |

|---|---|---|---|---|---|---|

| Office Spaces | ||||||

| Front Office | 350 | |||||

| Clerk | 1 | 80 | 80 | |||

| General Manager | 1 | 150 | 150 | |||

| Engineering Offices | 1 | 120 | 120 | |||

| Office Support Spaces | 80 | |||||

| Support/File Room | 1 | 80 | 80 | |||

| Tenant Suite (subtotal) | 430 | 1.34 | 575 | |||

| Receiving And Shipping | 4,100 | 1.09 | 4,481 | |||

| Docks | 4 | 400 | 1,600 | |||

| Staging | 1 | 2,500 | 2,500 | |||

| Production | 33,700 | 1.12 | 37,587 | |||

| Unprocessed Inventory | 1 | 1,000 | 1,000 | |||

| Processed Lines | 5 | 3,000 | 15,000 | |||

| Machinest Stations | 40 | 300 | 12,000 | |||

| Work in Process Inventory | 1 | 1,000 | 1,000 | |||

| Finished Testing | 4 | 500 | 2,000 | |||

| Finished Inventory | 1 | 1,500 | 1,500 | |||

| Maintenance Engineering Shop | 1 | 800 | 800 | |||

| Tool Crib | 1 | 400 | 400 | |||

| Tenant Suite | 38,230 | 1.12 | 42,643 | |||

| Tenant Usable Areas | 42,643 |

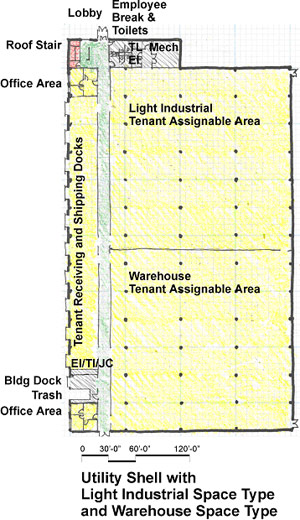

Example Plans

The following diagrams are representative of typical tenant plans.

Example Construction Criteria

For GSA, the unit costs for Light Industrial space types are based on the construction quality and design features in the following table . This information is based on GSA's benchmark interpretation and could be different for other owners.

Relevant Codes and Standards

The following agencies and organizations have developed codes and standards affecting the design of Light Industrial space types. Note that the codes and standards are minimum requirements. Architects, engineers, and consultants should consider exceeding the applicable requirements whenever possible.

- GSA PBS-P100 Facilities Standards for the Public Buildings Service

- ICC IBC International Building Code

Additional Resources

Publications

- ADA Checklist for Existing Facilities by the Institute for Human Centered Design and the ADA National Network. 2016.

- The Architectural Graphic Standards, 12th Edition by The American Institute of Architects, Dennis J. Hall. New York, NY: John Wiley & Sons, Inc., 2016.

- Industrial Manufacturing Trends 2019 by PWC Global. 2019.

- Top 10 Manufacturing Trends for 2019 by Joanne Phoenix. Global Manufacturing, Dec 07, 2018.