Overview

Within This Page

Warehouses are facilities that provide the proper environment for the purpose of storing goods and materials that require protection from the elements. Warehouses must be designed to accommodate the loads of the materials to be stored, the associated handling equipment, the receiving and shipping operations and associated trucking, and the needs of the operating personnel. The design of the warehouse should be planned to best accommodate business service requirements and the products to be stored/handled. The economics of modern commercial warehouses dictate that goods are processed in minimal turnaround time. Additionally, modern warehouses are becoming more sophisticated facilities that serve as hubs for high-tech tracking, repackaging, and quality control testing.

There are different types of warehouses including:

-

Heated and unheated general warehouses—provide space for bulk, rack, and bin storage, aisle space, receiving and shipping space, packing and crating space, and office and toilet space;

-

Refrigerated warehouses—preserve the quality of perishable goods and general supply materials that require refrigeration. Includes freeze and chill space, processing facilities, and mechanical areas; and

-

Controlled humidity (CH) warehouses—similar to general warehouses except that they are constructed with vapor barriers and contain humidity control equipment to maintain humidity at desired levels.

Special-designed warehouses meeting strict requirements can also provide liquid storage (fuel and nonpropellants), flammable and combustible storage, radioactive material storage, hazardous chemical storage, and ammunition storage.

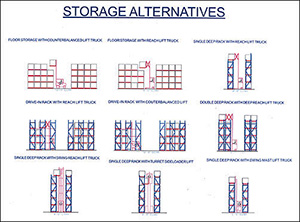

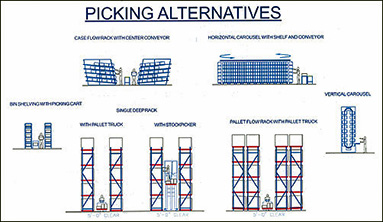

Features in warehouse designs include higher bays, sophisticated materials-handling equipment, broadband connectivity access, and more distribution networks. A wide range of storage alternatives, picking alternatives, material handling equipment, and software exist to meet the physical and operational requirements of the warehouse. Warehouse spaces must also be flexible to accommodate future operations and storage needs as well as mission changes.

Building Attributes

Being utilitarian facilities, warehouse designers should focus on making the warehouse spaces functional and efficient, while providing a safe and comfortable environment for the workers to increase productivity and control, reduce operating costs, and improve customer service. Even warehouses have to maintain a corporate image and provide for worker satisfaction. Building image and aesthetics, landscaping, and worker safety and comfort, become important issues in competitive real estate markets.

A. Types of Spaces

Depending on the program of the warehouse being designed, space types may vary dramatically. See also WBDG Warehouse Space Type.

- Storage Space

- Office Space

- Loading Docks for shipping and receiving

- Light Industrial Space

- Computer Centers

Loading dock technologies including automation and better design such as tighter dock doors help reduce accidents.

Photo Credit: ESI Group USA

B. Configurations

- Design the warehouse based on current and future needs.

-

Facilitate changes in business/agency growth, and size/population of office and warehouse spaces within the building. Warehouse space should be easily adapted to new functions such as office (on ground or upper levels), computer centers, or light industrial/fabrication.

-

Accommodate need for future loading docks, truck space, and car parking spaces if space configuration changes through effective site design.

-

Address material handling technologies and business practice, such as "just-in-time" storage, which have fundamentally changed operation of warehouses and distribution centers, and will continue to do so.

-

Include roof design with built-in extra structural capacity to handle addition of future rooftop equipment.

-

Design with fire protection capacity to accommodate storage of materials with a greater fire hazard; especially needed with high plastic product content or packaging, and plastic shrink-wrapped pallets.

-

- Maximize utilization of space while providing adequate circulation paths for personnel and material handling equipment such as forklift trucks.

- Use higher bays to take advantage of height allowances in the space.

-

Optimize layout and configuration for the warehouse operation, including efficient circulation and material handling and storage processes.

-

Relate interior and exterior receiving and shipping operations to the process flow of goods through the warehouse.

-

Separate receiving and shipping to avoid congestion at the loading dock areas in the building, and in the truck maneuvering areas.

-

Approach alternative material handling methods to determine other building aspects, such as aisle widths, lighting design, need for mezzanine space, fire protection, and egress design. Businesses will often use different methods of storage handling simultaneously for different products.

C. Durable / Functional

- Plan to accommodate loads of stored materials as well as associated handling equipment.

-

Design of warehouses is based on the dead and live load requirements of the structure as it will be built. Snow, wind, and seismic loads shall be considered where they are applicable. Racking in seismic areas must be built stronger and be better braced.

-

Wind uplift can cause great damage to roofs and metal roof copings at roof edges. Building codes recognize that wind velocity is greater across open areas, typical for warehouse zones.

-

Wind-driven rain can easily penetrate the vast surface areas of the warehouse walls. Design walls to permit any infiltrating water to evaporate harmlessly without collecting in the wall cavities or damaging stored product.

-

Proper floor types are an important consideration in the design. General warehouse space should be floored with a concrete slab to carry wheel loads and withstand the abrasion generated by the continual use of hard rubber and steel-wheeled forklift trucks. Consider adding hardeners and dustproofers to protect the concrete. Consider using epoxy coating on concrete floors near battery charging areas.

-

Floor flatness and levelness requirements are critical, especially for high ceilinged space and safe operation of high-lifting equipment.

-

Adequate space must be provided on-site for truck maneuvering, truck storage if the business owns a fleet, car parking for employees and future office space/population expansion (which might be driven by higher rent for center-city office space), and landscaped areas.

-

- Design to ensure that no structural member will interfere with the spacing of rail car doors or truck berths at dock spaces. Dock heights on the truck side of the terminal should be approximately 4'—4" above the pavement, with appropriate ramps at each truck berth to bring the height of the truck bed in line with the dock height. Dock heights on the rail side of the terminal should be approximately 3'–9" above the top of the rail to ensure that the rail car floor is even with the dock floor. Dock widths and areas inside exterior doors leading to dock space must be planned for maneuverability of forklift trucks and other expected types of material handling equipment.

-

Dock heights on the truck side of the terminal should be approximately 4'–40" above the pavement, with appropriate ramps, scissor lifts, or dock levelers at each truck berth to safely bring the height of the truck bed in line with the dock height.

-

Tops of doors should be high enough to accommodate full height pallet handling from the highest trucks.

-

Dock heights on the rail side of the terminal should be approximately 3'–9" above the top of the rail to ensure that the rail car floor is even with the dock floor.

-

Dock widths and areas inside exterior doors leading to dock space must be planned for maneuverability of forklift trucks and other expected types of material handling equipment. Use a non-slip finish on the concrete floor near loading areas for safety.

-

D. Sustainable

-

Select a location for the Warehouse building that is within close range of logistics hubs to reduce energy use and transportation costs. This can include urban areas, airports, and ports.

-

Design with passive solar concepts, solar geometry, and building load requirements in order to reduce energy loads. Use energy-efficient fixtures, windows, systems, and appliances, e.g., motion sensor instant-on lighting systems, wherever feasible.

-

Choose a light colored roof to reflect a large percentage of solar radiation, reducing HVAC loads, and energy consumption or a green roof to reduce storm water runoff, capture airborne particulates improving air quality, and reducing noise level. First cost is also reduced, due to the smaller plant size required. When a large roof area is anticipated, this effect can be significant, especially for temperature controlled warehouses. Greater heat reflection will increase worker productivity in the summer.

-

Plan with interior dock space in colder climates to reduce energy consumption and provide more tolerable winter working conditions for dock workers. Insulate dock areas to retain heat in winter and cool air in summer. Incorporate seals around loading docks to maintain temperatures when loading trucks and help minimize air infiltration.

-

Use ceiling mounted fans to reduce heat stratification and provide air movement, thus increasing worker comfort in both summer and winter. Mount fans above highest forklift level for worker safety.

-

Consider specifying white painted metal roof decking, thereby increasing ceiling surface reflectivity, lighting efficiency, and worker comfort without any added energy cost.

-

Incorporate water saving fixtures and equipment to protect and conserve water. Reduce the amount of paving around the warehouse when possible and landscape to provide shade for the building and surrounding paved areas. Incorporate drought-resistant or xeriscaping plants to reduce watering needs.

The Nike Distribution Center in Belgium is powered by five different on-site renewable technologies: wind, solar, geothermal, hydroelectric, and biomass. The minimum-footprint warehouse is a rack-supported building, with pathways made from recycled footwear material. In addition, more than 95% of the waste of the facility will be recycled.

Photo Credits: Nike

E. Safety / Security of Personnel, Equipment, and Materials

-

Address life-safety and health concerns including measures to prevent occupational injuries and illnesses (work-related musculoskeletal disorders (WMSD), trips, falls, etc.), ensure electrical safety, and eliminate exposure to hazardous materials. The following operations have historically contributed to significant numbers of warehouse injuries and are considered to be the most hazardous: docks, powered industrial trucks, conveyors, materials storage, manual lifting/handling, roof ladders and hatches, and charging stations. Other serious operational safety problems include inadequate fire safety provisions, improper blocking of exits and egress paths, chemical exposure, improper use of lockout procedures, lack of ergonomics, and failure to wear personal protective equipment.

-

Incorporate proper signage to clearly warn of hazards or to direct personnel to take precautions. The specific strategy for the warehouses signs must be determined early in the facility design process.

-

Include non-slip surface treatments on floors subject to wetting, such as outdoor docks, to eliminate slips and falls to personnel.

-

Design with fire sprinkler systems engineered to cover the specific commodity classification in the specific storage configuration for the planned warehouse. The adequacy of the sprinkler system must be evaluated when changes occur that can increase the hazard classification, such as introducing a new product line, using a different packaging material, or changing from wood pallets to plastic pallets.

-

Include appropriate security systems incorporated into the overall warehouse design.

-

Design the building to prevent pests and rodents from entering the facility and damaging wires, equipment, and materials. Install door sweeps; seal cracks; and eliminate gaps around utility lines and boxes. Plant vegetation so that it cannot touch the roof or other access points of the building; cover exterior drains and vents with metal mesh; and install plastic, one-way rodent-proofing valves inside all drains.

F. Health/Comfort

Examples of natural lighting designs for warehouse structures.

-

Provide proper ventilation under all circumstances.

-

Provide local exhaust for restrooms, kitchens, janitor's closets, copy rooms, battery-charging areas, etc.

-

Install CO2 sensors to provide real time monitoring of air quality.

-

Provide for natural lighting where possible. Provide lighting controls that turn off lights when sufficient daylight exists. Consider dimming controls that continuously adjust lighting levels to respond to daylight conditions. Integrate daylighting with the electric lighting system. Consider the different natural lighting designs for warehouses as shown above.

-

Minimize HVAC system noise in occupied space.

-

Incorporate equipment and furnishings reflective of healthy work practices to reduce or eliminate repetitive motions as well as prevent strains and sprains. Use furnishings, chairs, and equipment that are ergonomically designed and approved for that use.

- Create a 'sense of place' so the warehouse has a unique character that engenders a sense of pride, purpose, and dedication for individual workers and the workplace community.

G. Example Design and Construction Criteria

For GSA, the unit costs for this building type are based on the construction quality and design features in the following table . This information is based on GSA's benchmark interpretation and could be different for other owners.

Emerging Issues

Automated Storage and Retrieval Systems (AS/RS) are reshaping the ways in which goods and services are manufactured, stored, and distributed. AS/RS are an effective means to control and immediately report the movement of material, providing a critical link in the chain of information systems that control work-in-process, manufacturing schedules, and distribution. AS/RS warehouses are designed for maximum storage and minimum personnel on site. They are built for lower temperature operation with minimal heat and light needed, but require a tall structure with very level floors.

In the private sector, competition, technology and e-commerce are changing the way distributors move larger quantities of their products more quickly and efficiently to the consumer. Clustering distribution centers in a single geographic area is among the new trends. There is also a move towards transportation specialization, such as companies that depend on substantial parcel air transport, locating near Memphis, Tennessee, while Columbus, Ohio rates higher for companies focused on overland distribution.

Labor availability and technology advances are factors driving many companies to consolidate their distribution systems into fewer but larger, regional facilities. However, not all companies are consolidating their distribution centers: in many areas, the consolidation trend itself produces a new generation of smaller, local distribution centers. Experts say that new logistical handling systems and greater outsourcing—in particular, the increased use of third-party logistics providers—are driving this trend.

"Flex" warehouses in well landscaped industrial park settings for smaller businesses are a growing trend. These buildings accommodate small businesses such as contractors, light industrial fabricators, and mechanics that do not need exposure to heavy retail street traffic. In older industrial areas, small warehouse buildings with low roofs, no longer suitable for large single commercial users, are being repositioned and renovated as multi-tenant "flex" warehouse buildings.

This 85,000 square foot flex warehouse, located on the east side of Baltimore, Maryland, was designed as a shell to meet LEED Silver and Baltimore's Green Building Standards.

Photo Credit: Arium | AE

Relevant Codes and Standards

Warehouses must be designed to meet all local building, fire, and life-safety codes. When in doubt, consult with the local building official. The Occupational Safety and Health Administration (OSHA) also provides guidance for warehouse safety.

- Occupational Safety and Health Act of 1970 (29 U.S.C. § 651 et seq.)

- 29 C.F.R. Part 1903.1 et seq.—Inspections, Citations, and Proposed Penalties of Occupational Safety and Health Act of 1970

The following agencies and organizations have developed codes and standards affecting the design of Warehouse space types. Note that the codes and standards are minimum requirements. Architects, engineers, and consultants should consider exceeding the applicable requirements whenever possible.

- Department of Defense (DOD)

- National Fire Protection Association

- U.S. Access Board

- U.S. General Services Administration

Additional Resources

Organizations

- American Society of Safety Professionals (ASSP)

- Council of Supply Chain Management Professionals (CSCMP)

- Institute of Industrial & Systems Engineers (IISE)

- International Association of Refrigerated Warehouses (IARW)

- International Warehouse Logistics Association (IWLA)

- Occupational Safety and Health Administration (OSHA)

- The International Society of Logistics (SOLE)

- Warehousing Education and Research Council (WERC)

Publications

- Architectural Graphic Standards, 12th Edition by The American Institute of Architects, Dennis J. Hall. New York, NY: John Wiley & Sons, Inc., 2016.

- "Guide to Sizing Warehouse Aisles for Various Types of Lift Trucks" by Edward Brown. WarehouseIQ.com, October 8, 2011.

- Rules of Thumb: Warehousing and Distribution Guidelines, 11th edition by TranSystems, 2010.

- The Time, Space & Cost Guide to Better Warehouse Design, Second Edition by Maida Napolitano and Gross & Associates. August 24, 2017.

- Warehouse Safety: A Practical Guide to Preventing Warehouse Incidents and Injuries by George Swartz. 1999. ISBN: 0865876479

- Warehousing Profitably, Third Edition by Kenneth Ackerman. The Distribution Group, 2011.

Websites

Others

- Building Research Information Knowledgebase (BRIK)—an interactive portal offering online access to peer-reviewed research projects and case studies in all facets of building, from predesign, design, and construction through occupancy and reuse.