Introduction

Within This Page

Water conservation technologies and strategies are often the most overlooked aspects of a whole-building design strategy. However, the planning for various water uses within a building is increasingly becoming a high priority. This is due to a number of reasons, namely that new and existing water resources are becoming increasingly scarce in a number of regions throughout the country; per capita water consumption is increasing annually; water and sewer rates have increased dramatically over the last decade (100–400%); and new water supply options are too costly or altogether unavailable—often resulting in stringent water use requirements in new construction applications. In addition, there is the increasing recognition of the water, energy, and O&M savings that can be realized through the implementation of water saving initiatives.

Within the federal sector alone it is estimated that expenditures for water and sewer services reach up to $1 billion annually. Further, it is estimated that through moderate gains in water efficiency the federal government could save as much as $240 million per year. Water savings at these levels, approximately 40%, could provide enough water to supply a population of approximately 1.8 million. This water savings potential is enormous with relatively low cost expenditures. There are also significant energy cost savings associated with water efficiency measures. For example, federal facilities use approximately 60 billion Btu of energy annually to process and use water. Over ninety-eight percent of this energy is used for water heating, further illustrating that water conservation measures are an integral part of a facility's overall energy management plan. A general definition of water efficiency planning is as follows:

Water efficiency is the planned management of water to prevent waste, overuse, and exploitation of the resource. Effective water efficiency planning seeks to "do more with less" without sacrificing comfort or performance. Water efficiency planning is a resource management practice that incorporates analysis of costs and uses of water; specification of water-saving solutions; installation of water-saving measures; and verification of savings to maximize the cost-effective use of water resources.

Description

A. Water Conservation Strategies

There are a number of strategies that can be employed to reduce the amount of water consumed at a facility. In general terms, these methods include:

- System optimization (i.e., efficient water systems design, leak detection, and repair);

- Water conservation measures; and

- Water reuse/recycling systems.

More specifically, a wide range of technologies and measures can be employed within each of these strategies to save water and associated energy consumption. These include:

- Water-efficient plumbing fixtures (ultra low-flow toilets and urinals, waterless urinals, low-flow and sensored sinks, low-flow showerheads, and water-efficient dishwashers and washing machines)

- Irrigation and landscaping measures (water-efficient irrigation systems, irrigation control systems, low-flow sprinkler heads, water-efficient scheduling practices, and Xeriscape)

- Water recycling or reuse measures (Gray water and process recycling systems), and

- Methods to reduce water use in HVAC systems.

The following list of measures describes the technologies, strategies, and techniques that can be specified in the design phase of a new construction project to reduce facility water use. The measures are commensurate with the U.S. DOE's Federal Energy Management Program's "Guidance to Establish Water Efficiency Improvement Goal for Federal Agencies", which details "Best Management Practices" that all federal facilities must consider for implementation per Executive Order 13693.

B. Best Management Practices

1. Public Information and Education Programs

U.S. Department of Energy, Federal Energy Management Program

While not a design specification or technology option, obtaining the participation of building inhabitants in the water conservation program is a key to achieving water use reduction goals, and is often one of the simplest and most cost-effective strategies to employ. One of the first steps in implementing a water conservation program is to train employees on the use of new water-efficient technologies, as well as maintenance staff on O&M procedures; technologies that are not properly used or maintained will not achieve their maximum savings potential. For example, double flushing of ultra-low flush toilets may result in more water consumption than older, conventional devices. The following bullets summarize some of the activities that can be incorporated into a public information and education program:

- Establish hot line or other reporting mechanisms to report leaks and waste;

- Place signs on new equipment on how to use;

- Initiate a suggestion or incentive program;

- Distribute flyers and pamphlets to increase awareness of the facility's water management plan and educate inhabitants on wise water use practices; and

- Develop a display on water management highlighting the practices in use at the facility (i.e., Xeriscape, ULF toilets, water reuse, etc.) and its resultant savings and benefits and place in a highly visible area of the building.

The human factor is critical to obtaining the desired results from water conserving strategies, and development of an information and education campaign can help your facility in making the human factor work in favor of water conservation initiatives.

2. Distribution System Audits, Leak Detection, and Repair

Performance of a water distribution system audit is not limited to existing, aged buildings. Water system leaks can occur in new construction from improper installation of piping and fixtures, or impacts to piping systems during the construction process. Therefore, during the design process it is essential to develop a water budget for the new building, and commission the water distribution system as part of the overall building commissioning process. If estimated water consumption is greater than 10% of the baseline water budget established during the design process, then a leak detection study may be warranted. Contact your local water utility for assistance, as many perform the service for free or a minimal fee. Water system leaks that are not repaired immediately can damage building structures, since even a small leak can result in the loss of large quantities of water over time. In addition, un-repaired leaks will result in increased water bills. Metering of individual facilities is a water saving measure that should be given serious consideration. With un-metered service, leaks go undetected; water is wasted; and there is no accountability and therefore, no incentive to save.

3. Water-Efficient Landscaping

Landscaping water usage can easily account for 20% or more of facility water consumption, and is a key area to target for water use savings. There are three major components to designing a water-efficient landscape for a new facility: 1) reduce the amount of turf and other irrigated areas 2) ensure water-efficient design of irrigation systems, and 3) specify native or climate appropriate landscape materials (Xeriscape). Reducing the amount of turf grass and overall irrigated areas will reduce water consumption and associated costs, and will result in time and dollar savings from mowing, fertilizing, waste removal, and maintenance. Remaining landscape areas that require irrigation should utilize water-efficient irrigation systems (low-flow sprinkler heads, efficient system design and layout, and optimized irrigation schedules and controls) to minimize water use and maximize plant health. Utilizing Xeriscape strategies whenever practicable will save on water, fertilizer, pruning, maintenance, labor, and overall costs.

Colorado Springs Utilities, Xeriscape Demonstration Garden Colorado State University Cooperative Extension

Xeriscape is the use of native or climate appropriate plants that are adapted to the local climate, and thus require less water, are more likely to survive drought conditions, and are more pest and disease tolerant. A complete Xeriscape strategy also considers the climate appropriate plant's growth patterns, maintenance requirements, and their interaction with local climate and soil conditions.

4. Toilets and Urinals

Toilet and urinal flushing typically account for nearly one-third of a building's total water consumption, and this end-use is one of the simplest and lowest cost areas to target for significant water and sewer savings. Federal law requires that commercial toilets manufactured after January 1, 1997 must use no more than 1.6 gallons per flush (GPF) and urinals must use no more than 1 gpf. Some earlier versions of ultra-low flush (ULF) toilets designed to meet this standard did have some operational problems and were prone to clogging or required double flushing.

The Waterless Company Waterless Urinal and American Standard ULF Toilet

Newer ULF toilets have alleviated these problems, and surveys indicate a consumer satisfaction level of greater than 80%. ULF toilet products are offered in three classifications: 1) flush valve, 2) pressure-assisted, and 3) gravity toilets. In general, the flush valve and pressure-assisted ULF toilets perform better than gravity toilets since they use the water system pressure to assist in their operation. ULF urinal products are typically offered in four categories: 1) siphonic jet, 2) washout and washdown, 3) blowout, and 4) waterless. These various ULF product offerings' effectiveness varies widely based upon frequency of usage; some are designed for low volume traffic, others for high volume traffic (see GSA's Water Management GuideDownload waterguide_new_R2E-c-t-r_0Z5RDZ-i34K-pR.pdf for more information). Waterless urinals have gained widespread acceptance, as they are made of a urine-repellent surface; have no flush handles or moving parts; and virtually require no water. They do utilize a trap containing liquid that separates the urine from indoor environment which requires periodic replacement. Additional savings in the area of toilets and urinals can be achieved by utilizing non-potable water for flushing, or utilizing composting or incinerator toilets where sewer service is not available.

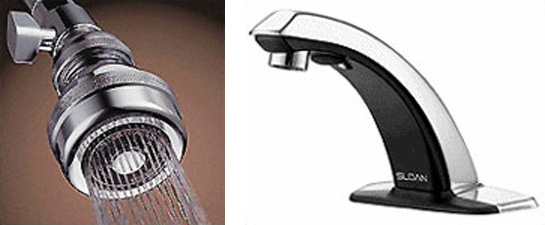

5. Showerheads and Faucets

Federal legislation passed in 1992 (EPAct) requires that all U.S. plumbing manufacturers and importers meet or beat the following water-efficiency standards for new fixtures: showerheads—2.5 gallons per minute; and faucets—2.5 gallons per minute. Through the specification of water-using fixtures that meet or exceed these standards, significant amounts of water and the associated energy used to heat water can be saved. New showerheads that are designed to the federal standards typically incorporate a narrower spray area and a greater mix of air and water than older showerheads. As a result, less water is used while no discernible difference in quality or comfort is perceivable by the user. Newer models and features of these low-flow showerheads include: 1) atomizers that deliver water in small but abundant droplets that cover larger surface areas, 2) pulsators that vary spray patterns with pauses between spurts or through pulsating between strong flow and light mist, and 3) aerators which mix water droplets with air to cover the desired surface area. Low-flow faucets also employ the use of aeration technology, as well as sensors, to achieve water savings at equivalent comfort levels to older, more consumptive fixtures. Examples of newer low-flow faucet technologies include: 1) metered valve faucets that deliver a preset amount of water and then automatically shut off (the federal standard for this fixture type is 0.25 gallons per cycle); 2) self-closing faucets that are spring-loaded to shut off the faucet a few seconds after the user turns it on, and 3) ultrasonic and infrared sensor faucets that automatically activate the faucet when hands are detected beneath it, and automatically shuts off the water when the hands are removed. It is important to note that with each of these technologies the water system pressure should be between 20-80 PSI; pressures below this range will result in low-flow devices not operating properly, and pressures above this range will result in reduced water savings.

Sloan-o-matic Low Flow Showerhead and Sloan Automatic Faucet with Infrared Sensor

6. Boilers and Steam Systems

Boilers and steam generators are used in large heating systems, institutional kitchens, and in facilities that require large amounts of processed steam. Many of these systems use large amounts of water to make hot water and/or steam that is then subject to losses from leaks and "blow-down". Water consumption rates vary for boiler and steam systems depending on system size, steam requirements and amount of condensate return, and the cost of make up water is relatively small compared to the cost of energy and chemicals required to heat and treat the water. However, these ancillary savings can be significant in themselves. Strategies to achieve water and cost savings from boiler and steam systems are highly site specific, but may include: 1) properly sizing boiler and steam units (and possibly downsizing units by reducing facility heat and steam requirements—and thus reducing makeup water requirements), 2) specifying the most life-cycle cost-effective system option, and not just the lowest first cost option, 3) installing a small summer boiler or distributed system for reheat or dehumidification requirements instead of inefficiently running a large boiler at part load, and 4) considering alternative technologies such as heat pumps for small loads.

7. Single-Pass Cooling Equipment

Single-pass, or "once-through", cooling equipment circulates water one time through a piece of equipment to cool it, then the water is discharged (often to the sewer line). Single pass cooling equipment is often specified for such end-uses as: CAT scanners, degreasers, hydraulic equipment, condensers, air compressors, welding machines, vacuum pumps, ice machines, x-ray equipment and air conditioners. Using water for only one cycle and then discharging it results in significant waste, and this process can be avoided in many instances. Strategies to reduce waste from single-pass cooling include: 1) specifying multi-pass, closed loop, or air-cooled equipment options (note that some equipment types may not function properly if other than single-pass is specified, be sure to check with equipment manufacturer first) to arrive at the most water- and energy-efficient cooling system, 2) specify an automatic shut-off valve to the cooling system to eliminate usage when equipment is not running (to be used only on equipment where indoor air quality is not a concern), and 3) find alternative uses for single-pass effluent such as landscaping, boiler or cooling tower make-up water, toilet flushing, etc. (ensure that effluent does not contain any waste stream such grease or chemical agents).

8. Cooling Tower Management

Cooling towers assist in regulating indoor air temperature of a building by either rejecting heat from air-conditioning systems or by cooling hot equipment, and require vast amounts of water to perform these functions. The thermal efficiency, proper operation, and longevity of the water cooling system all depend on the quality of water and its reuse or recycling potential. Cooling tower water is lost through evaporation, bleed-off, and drift. To replace this lost water more make-up water must be added. To displace the use of potable water used in cooling towers, sometimes water used for other purposes within a facility can be recycled and reused as make-up water with little or no pre-treatment, including: 1) water used in a once-through cooling system, 2) pretreated effluent from other processes, provided that any chemicals used are compatible with the cooling tower system, and 3) high-quality municipal wastewater effluent or recycled water (where available). Additional measures that improve the efficient utilization of water in cooling towers include:

- Installing a sidestream filtration system composed of a rapid sand filter or high-efficiency cartridge filter to cleanse the water. These systems draw water from the sump, filter out sediment, and return the filtered water to the tower, enabling the system to operate more efficiently with less water and chemicals.

- Installing covers to block sunlight penetration and inhibit algae growth

- Installing automated chemical feed systems on large cooling tower systems (over 100 tons). These systems minimize water and chemical use while optimizing control against scale, corrosion, and biological growth.

While potable water savings may be significant through implementation of these measures, additional cost savings may also be accrued through ancillary reductions in energy and chemical usage.

9. Miscellaneous High Water-Using Processes

Numerous site-specific processes requiring high water use are found within federal facilities. These processes and/or end uses include kitchens and food processing, vehicle washing stations, laboratory uses, cleaning/laundry facilities, fish hatcheries, treasury production, and more. Each of these end uses and their application within federal facilities presents site-specific opportunities and challenges for reducing water usage. For new facility design, each high water-using process should be identified and estimated usage quantified—and then reviewed and analyzed for potential energy and water savings measures. Some processes may require outside expert assistance to identify the most applicable and beneficial water savings options.

Water Recirculation System at Mora National Fish Hatchery and Technology Center

10. Water Reuse and Recycling

Many facilities have water use requirements that may be met with non-potable water. Using non-potable water to meet these requirements can result in significant water and dollar savings from avoidance of potable water purchases and sewerage costs. The use of non-potable water resources is often more cost-effective if applicable end-uses are identified early on in the building design process. There are four general strategies that can be employed for utilizing reused or recycled water.

On-site water reuse or recycling: this process relies on reusing water from the same purpose at the same location, and usually involves minimal treatment or filtration to make it acceptable for its intended reuse. Examples include rinse water that is filtered from car washing and laundry uses and then used in the next wash cycle.

Reclaimed/treated water: this non-potable water resource is developed by treating used water to wastewater treatment standards and then redistributed for on-site use. This strategy can be costly, but may still be cost-effective due to offsets of potable water purchases and sewerage costs. Non-potable water meeting wastewater treatment standards can be used for end uses such as landscape irrigation, decorative fountains, cooling tower makeup water, toilet flushing, fire sprinkler systems, and other on-site industrial processes.

Gray water: this resource is derived from water captured from uses such as showers, baths, sinks, and laundries (excluding diaper washing and food processing) and then filtered to remove solids. Gray water may be used to serve such end uses as landscape irrigation (preferably subsurface) and toilet flushing.

Water catchment systems: this resource includes non-potable water captured from rainwater sources or from rivers, lakes, ponds, and wells that have not been treated to meet potable standards. Rooftop rainwater collection systems are becoming increasingly popular, and the captured water can be stored in architecturally aesthetic cisterns. End uses that can be served by this resource include landscape irrigation, single pass cooling, and toilet flushing.

For each of the strategies described above, it is imperative to review all applicable federal, state, and local standards and permitting requirements for treating and utilizing non-potable water resources. For example, many jurisdictions do not allow gray water use due to health concerns.

Planters with copper piping beneath delivering gray water at the Society for the Protection of New Hampshire Forests.

Rainwater catchment system with cisterns at Philip Merrill Environmental Center, Annapolis, Maryland.

C. Accessible

With the exception of plumbing fixtures, none of the strategies described in this section fall under ADA requirements. Applicable plumbing fixtures are available in ADA compliant models.

D. Aesthetics

All of the strategies detailed in this section are equally or more aesthetic than conventional options. Many water conservation options may be aesthetically superior to conventional water-using strategies (i.e., Xeriscape, plumbing fixtures, and cisterns).

E. Cost-Effective

Cost savings are provided by the reduction of utility potable water purchases and sewerage costs. In addition, many water conservation strategies also reduce hot water and/or water treatment requirements resulting in cost savings from reduced energy and chemical usage. Some strategies can be cost-effective based on these ancillary savings alone.

Reducing water requirements also provides greater predictability of utility water and sewer costs, and reduced vulnerability to utility price volatility.

Through the reduction of end-use water use requirements it may be possible to reduce the diameter of piping systems or eliminate some piping runs altogether (i.e., water supply line to waterless urinal), thus reducing construction costs. In addition, some water utilities charge customers based upon the diameter of the distribution line at the meter; if this line size can be reduced, further reductions in utility water bills may be achievable.

F. Durable

All of the strategies discussed in this section are of equal or greater durability than conventional technologies. Some water conserving technologies may be even more durable and last longer than conventional technologies.

G. Functional

All strategies and technologies provide equal or greater levels of functionality compared to conventional methods. Some models of water-conserving technologies, such as showerheads, are known to provide an even greater level of performance and quality than conventional technologies. In addition, some early models of water-conserving technologies, such as ultra-low-flush toilets, experienced problems with decreased functionality; however, newer versions of these fixtures have alleviated this concern.

H. Productive

Water conservation strategies are designed based on the principle of "doing more with less" without sacrificing productivity, performance, comfort, or quality. As such, these strategies typically increase productivity per unit of water input.

I. Secure/Safe

Reducing water consumption increases security by minimizing facility impacts from droughts and other water shortage related events.

Health safety may be a concern if utilizing non-potable water resources on-site. Check all applicable federal, state, and local regulations and permit requirements prior to using non-potable water.

J. Sustainable

Reducing potable water requirements through conservation technologies and reclamation/recycling/reuse strategies is a core element of a sustainable facility design initiative. By minimizing water requirements, the facility is reducing the impacts on the entire water infrastructure including reductions in groundwater pumping, water treatment and its associated energy and chemical usage, distribution pumping, and sewer water reclamation and treatment. In addition, reductions in on-site energy use and chemical treatment may be reduced. The result is obtaining the most use from the least amount of water with the least impact, and may also result in reducing or eliminating the need for development of additional costly water resources in the future.

Application

The following case studies provide information on various water conservation strategies employed at a number of federal facility types throughout the country:

- EPA Environmental Management Center Fort Mead, Maryland (water management plan, cooling tower efficiency)

- EPA National Vehicle and Fuel Emissions Laboratory Ann Arbor, Michigan (water management plan, single-pass cooling equipment, cooling tower downsizing, performance contracting)

- EPA New England Regional Laboratory Chelmsford, Massachusetts (water management plan, xeriscape)

- U.S. Department of Energy, Federal Energy Management Program Water Management Awards

Relevant Codes and Standards

Industry Standards

The Energy Policy Act of 1992 requires all U.S. plumbing manufacturers and importers to meet or beat the following water-efficiency standards:

- Faucets: 2.5 gallons per minute

- Metered valve faucets: 0.25 gallons per cycle

- Showerheads: 2.5 gallons per minute

- Toilets: 1.6 gallons per flush

- Urinals: 1.0 gallons per flush

Government Standards

- Executive Order 13693, "Planning for Federal Sustainability in the Next Decade"

- Guiding Principles for Sustainable Federal Buildings

Federal Mandate

Additional Resources

Federal and State Agencies

- California Department of Water Resources, Office of Water Use Efficiency

- U.S. Department of Defense, Air Force Civil Engineer Center

- U.S. Department of Defense, Army Corps of Engineers

- U.S. Department of Defense, Navy

- U.S. Department of Energy, Federal Energy Management Program, Water Efficiency

- U.S. Environmental Protection Agency, Water Management

Associations/Organizations

- American Society of Landscape Architects

- American Water Works Association

- California Urban Water Conservation Council

- The Irrigation Association

- Xeriscape Colorado, a program of Colorado WaterWise.

Publications

- Air Force Water Conservation Guidebook

- UFC 3-240-02 Domestic Wastewater Treatment

- GSA Water Management GuideDownload waterguide_new_R2E-c-t-r_0Z5RDZ-i34K-pR.pdf

- Roadside Use of Native Plants, Federal Highway Administration

- Water Audits and Loss Control Programs by American Water Works Association. AWWA Number M36

Design and Analysis Tools

- GEMI Water Sustainability Tool

- GSA Sustainable Facilities Tool (SFTool)—SFTool's immersive virtual environment addresses all your sustainability planning, designing and procurement needs.

- Watergy—a spreadsheet model that uses water/energy relationship assumptions to analyze the potential of water savings and associated energy savings