Introduction

Within This Page

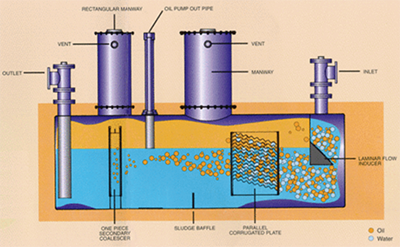

Oil-Water Separators are multi-chambered devices used to remove oil from water. Oil-water separation applications include industrial processes, such as the petroleum industry, metal working industry, bilge water from ships and the food industry which would include fats, oil, grease (FOG), and others. Oil-water separators may also be used as pretreatment prior to primary treatment at a water resource recovery facility, or as treatment for storm water runoff from areas where hydrocarbon products are handled or spills are likely such are vehicle wash areas or fueling stations. In addition to collecting oil, oil-water separators collect sediment.

There are two primary types of oil-water separators: gravity and coalescing plate. Generally, oil-water separators consist of three chambers: a forebay, a separator section, and an afterbay. As the oil-water mixture progresses through the system, the oil naturally separates from the water and floats to the surface where it is removed. With proper design, good maintenance, and a limited use of certain chemicals, oily water can be effectively and economically treated.

Diagram of the oil-water separation process

Description

Gravity Separators

Gravity separators are often called API oil-water separators as they are designed in accordance with standards published by the American Petroleum Institute. In the first chamber of a gravity separator, the wastewater enters the system where a baffle slows flow, reduces turbulence, and allows sediment to fall to the bottom. The second chamber traps and holds oil as it separates and rises in the water and allows for additional sediment to collect at the bottom and oil to collect at the surface for removal. The final chamber provides relatively oil-free water before being discharged. This type of oil-water separator works efficiently for most wastewater as long as certain characteristics (oil droplet size, water temperature, etc.) are met.

Coalescing Plate Separators

Coalescing plate separators also consist of three chambers and use the same principles as gravity separators but introduce inclined parallel plates that increase the effective surface area of the system, allowing for the same oil removal with a smaller footprint. Although more efficient, the parallel plates require additional maintenance to prevent fouling, increasing the cost of this system.