by Joseph C. Dean, P.E. and Nicholas A. Silver for the Director, Corrosion Policy & Oversight (DCPO), (DASD) [Materiel Readiness]

Updated: 09-30-2021

INTRODUCTION

Within This Page

This page is intended to help Facility Planners, Managers, Architects and Engineers understand and be able to assess and plan for facilities CPC requirements and to make informed decisions at the appropriate time in the facilities life cycle to ensure that the desired levels of durability and sustainability are achieved. The creation of project documentation and preliminary estimates must address appropriate CPC considerations such that sufficient funding is included. This will ensure that the acquisition process, including design and construction, will have the necessary life cycle CPC features in the completed facility. This will result in reducing CPC deficiencies before they cause failure with the resulting impact on sustainment costs and life cycle.

DESCRIPTION

The Department of Defense (DoD) acquires, operates, and maintains a vast array of physical assets that include vehicles, aircraft, ships, materiel and facilities such as wharves, buildings, and other stationary structures and infrastructure. All these assets are susceptible to corrosion. Corrosion affects mission readiness, facility capacity and downtime, personnel productivity, and asset employment as well as safety, health, and quality of life that directly impacts morale. Corrosion is most often associated with "rust" on steel and the oxidation of other metals. However, 10 U.S.C. § 2228 defines corrosion is, "the deterioration of a material or its properties due to a reaction of that material with its chemical environment." It is inclusive of the deterioration of all materials, which can be caused through sun exposure, mold and mildew, wind, and other environmental elements.

The method and rate by which this reaction occurs are directly affected by the severity of the local environment. Several methods for classifying and quantifying the corrosive effects of atmospheric environments and service conditions have been developed over the years.

Environmental Severity describes the corrosivity of the local environment of a given location or region and contributes directly to the occurrence of corrosion. The effects of corrosion and the rate at which it occurs are consequences of the corrosion system, which is comprised of a material or physical system, the environment and operational conditions. Corrosion can occur in many different forms including uniform or general, galvanic, crevice, pitting, de-alloying, inter-granular, fatigue, erosion and flow-assisted, fretting, stray current, and stress corrosion cracking. See the Corrosion Science Knowledge Area for more information.

Facilities assets affected by corrosion are extensive. They include pipelines, tankage, pavements, roofs, transformers, switchgear, electrical boxes, HVAC equipment, water towers, fire hydrants, motors, compressors, bridges, wharfs, piers, connectors, fencing, steam and water distribution lines, boilers, ladders, stairways, wash racks, fire sprinkler systems, and airfield pavements. The effects of corrosion often remain unseen or unnoticed until failure occurs. For example, incorrect selection or application of a coating to a structure such as a bridge or a tower where corrosion ultimately affects the structural integrity, or when designers or constructors fail to consider design geometrics that ultimately trap water or other corrosive materials causing roof or structural failures.

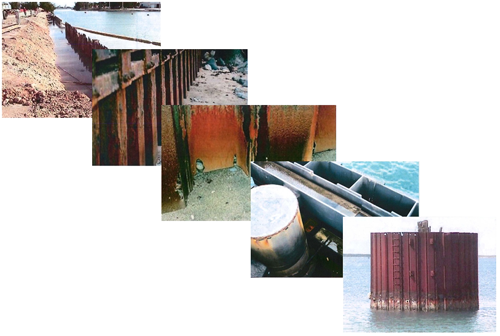

Photo 1: Examples of waterfront corrosion

Source: Waterfront Pictures - Steve Geusic P.E, LEIDOS

Photo 2: Examples of site corrosion

Source: The Facilities and Infrastructure Corrosion Evaluation Study 2013

The Planning Process and Corrosion

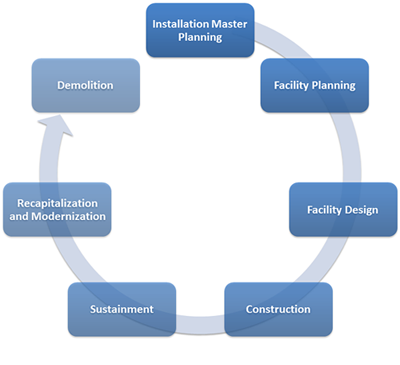

To be effective, CPC must be considered in the planning process for new or renovated facilities to achieve required life cycle durability and sustainability levels. This formal process engages facilities professionals with experience in the facilities life cycle.

Figure 1: The Facilities Life Cycle

Source: Office of the Assistant Secretary of Defense for Energy, Installations, and Environment

Planning can be defined as a "detailed scheme or method for attaining an objective or a proposed idea" before fully pursuing a project. The DoD utilizes various planning approaches to ensure that only the most essential facilities are constructed. During that planning process, much is considered including functional requirements, available budget, specialized design features, suitability of the proposed site, durability expectations and many other important aspects affecting the project, the installation, the mission supported, the regional influences, and the environmental severity at that location. To ensure that new weapons programs are supported, detailed analysis via an Integrated Product Support (IPS) and Integrated Logistics Assessment (ILA) may be conducted. Planning for key supportability requirements are considered during this analysis such as operations, training, maintenance, and supply. DoD Instruction 4165.70, Real Property Management , requires that "Base master plans or comprehensive plans shall be developed for all installations," and "shall:

Be developed by the DoD Component having management responsibility for the installation. Be based on a strategic assessment of the operational mission and expected use of the installation. Cover at least a 10-year period and be updated every 5 years (more often if necessary). Include a specific, annual listing of all construction to include military construction, military family housing, non-appropriated fund construction, commissary surcharge construction, appropriated fund construction for a non-DoD agency, and construction privately financed over the time period covered by the plan. Include a specific, annual listing of all major repair and sustainment projects, as well as restoration and modernization projects needed within the time period covered by the plan. Include current and projected peacetime as well as mobilization requirements.

NOTE: Military Construction (MILCON), as defined in 10 U.S. Code § 2801, is "Any construction, development, conversion, or extension of any kind carried out with respect to a military installation, whether to satisfy temporary or permanent requirements, or any acquisition of land or construction of a defense access road (as described in Section 210 of Title 23)." A Repair Project is defined in 10 U.S. Code 2811 as a project to restore a real property facility, system, or component to such a condition that it may effectively be used for its designated functional purpose; or (2) to convert a real property facility, system, or component to a new functional purpose without increasing its external dimensions.

Figure 2: Army Master Planning Presentation

Source: Public Works Digest, January/February 2007, U.S. Army Installation Management Command

See FIM Program Areas for specific guidance on preparing Master Plans and the associated impacts on an installation and the mission it supports. Consistent with this guidance, UFC 2-100-01, Installation Master Planning, was developed to facilitate reduction in maintenance costs and minimize overall lifecycle costs. The UFC states that: "Planners will evaluate the natural environment with a particular focus on those elements that may create significant limitations on the operation, construction, or sustainment of buildings, roadways, utility systems, runways, training ranges, airfields, and other facilities." The UFC 1-200-01, DoD Building Code, requires corrosion related considerations for DoD Installations.

While these requirements and programs address facilities and infrastructure "planning," that effort generally occurs way in advance of actually developing a design for the specific facility. Often, these project plans and the associated documentation may not be detailed enough to allow for the inclusion of CPC requirements unless the planning initiative is focusing on a specific facility or group of facilities to be constructed or sustained in a high corrosion area such as Guam (C4 and C5) or a waterfront (C4 or C5) location. (These environmental severity categories are based on/in accordance with ISO 9223:2012, Corrosion of metals and alloys - Corrosivity of atmospheres - Classification, determination and estimation. ISO Corrosivity Categories range from C1 (very low) to C5 (very high) and CX (extreme). CX is generally reserved for offshore environments). Those details are often left to be resolved during or even after the development of the RFP and the award of the contract, which includes plans and specifications. Corrosion vulnerability and the potential effects of corrosion need to be fully evaluated as a requirement and part of project planning, design, construction, durability assessment and sustainment phases and activities. Facilities Corrosion Impacts on Operations and Mission provides insights related to CPC that should be considered by planners during the 1391 development.

Whether it is a small project (such as the application of a coating to mitigate the deterioration of a surface) or one that is more complex (such as the construction of a facility in a highly corrosive environment), the basic tenets of planning and programming apply. Assessment of project requirements must include mission demands, facility operations tempo, life cycle and durability expectations, and the environment where the project is to be located. For the project to be successful through the phases of design, construction, and ultimately sustainment, these factors must be considered and appropriately described in project documents and included in the cost estimate.

CPC presents a more challenging problem for already existing facilities. With limited budgets, sustainment, restoration, and modernization (SRM) actions must address the most urgent deficiencies while maintaining material condition consistent with the operational readiness requirements of the installation. SRM processes may require planning, programming, design, engineering, and acquisition, each of which has corrosion-related decision events that affect both service life, durability and life cycle costs.

The DD Form 1391 is the principal project justification document to express the user's facility-related needs, request authorization through the service's chain of command, and apply for authorization and funding from Congress. A DD Form 1391 must include detailed, informative statements as to why the project is needed. It must also identify every primary and supporting facility required to complete the construction, as well as the unit of measure, unit quantity, and unit cost for each facility. For projects that require congressional authorization, 10 USC 2853, establishes legal requirements for staying within the project scope of work identified by a DD Form 1391.

The DD Form 1391 includes only minimal technical details. This restriction extends to information related to corrosion, unless the project consists of facilities inherently more vulnerable to the effects of corrosion. For example, a steel water storage tank construction project may call out protective coating and cathodic protection requirements. The focus of the DD Form 1391 is on functional requirements and may include only a brief description of CPC requirements. The CPC costs are included as part of the overall engineering discipline costs (electrical, structural, etc.), except when specialized CPC work is required, and the project document includes separate line items for CPC costs.

Planning and programming of MILCON projects generally follows standard military service or DoD submission and approval processes. The installation or service agency, such as the OSD Tricare Management Activity (TMA) for the Guam Hospital (Figure 4), determines the requirements during the planning stage and prepares DD Form 1391 project documentation for review and prioritization by the chain of command, with the eventual submission for OSD, service, and ultimately congressional approval. It should be noted that project planning documents for the Guam Hospital acknowledged the effects of the harsh tropical environment, and pre-design charettes resulted in a basis of design that noted numerous design criteria documents that contain references to corrosion prevention and control. Specific CPC requirements were identified during the design phase.

Photo 3: U.S. Naval Hospital Guam (opened 2014)

Source: U.S. Navy photo by Jesse Leon Guerrero/Released

For projects that are below the MILCON threshold, the timeline for accomplishment is normally shorter. These projects should be part of a master facilities investment plan as well, but in some cases, they maybe maintenance and sustainment actions that are part of a shorter plan. In that case, the "planning" process for these projects definitely should be more thorough and inclusive of CPC requirements.

Facility sustainment is defined by DoD Financial Management Policy and Procedures (DoDI 7000.14), Volume 2B, Chapter 8. Sustainment includes regularly scheduled maintenance as well as cyclical repairs or replacement of components over the expected service life of facilities. Because of obsolescence, sustainment alone cannot extend the life of a facility indefinitely. Insufficient funding for sustainment results in a reduction in service life and durability. Repair or replacement required earlier than expected because of a lack of sustainment is known as restoration.

Restoration and modernization (RM) involves the renovation or reconstruction activities needed to keep existing facilities modern and relevant in an environment of changing standards and missions. RM extends the service life of facilities, restores lost service life, or updates and alters a facility for adaptive reuse. RM includes restoration, modernization, or replacement of facilities, but not the acquisition of new facilities. RM may also include the demolition of deteriorated facilities if demolition is part of the renovation process. Repair of facilities is defined in 10 USC 2811, as "a project to restore a real property facility, system, or component to such a condition that it may effectively be used for its designated functional purpose." The section provides language on prohibitions related to new construction additions and delineates congressional notification requirements.

Successful execution of SRM programs by the military services is essential to ensure that facilities continue to meet mission requirements. CPC represents a very large area of SRM focus. Identifying CPC deficiencies, then determining how and when to resolve those deficiencies, is a major challenge for the facilities community. Consequently, CPC management is an essential part of the ongoing initiative to sustain DoD's facilities and installations. Table 1 should help the facilities Planner place these requirements with the associated risks and mission impacts in perspective when considering the scope of a new project.

Selecting the appropriate acquisition strategy is an essential aspect of a mature planning process. Knowing whether a design-bid-build, design-build or simplified acquisition is to be utilized will help the planner know the extent of CPC to be included in project justifications.

- The term "acquisition" refers to the acquiring, by contract and with appropriated funds, of supplies or services (including construction) by and for the use of the federal government through purchase or lease, whether the supplies or services are already in existence or must be created, developed, demonstrated, and evaluated. The term "acquisition" throughout the report is in reference to facilities and infrastructure.

- Indefinite delivery, indefinite quantity (IDIQ) contracts are widely acknowledged as a good mechanism for single discipline project work (such as painting, HVAC, roofing, roads, and electrical). Some installation representatives commented they have IDIQs developed for each major SRM area. IDIQs allow quick delivery order award (within hours, as opposed to months). Many organizations expressed an interest in blanket IDIQ contracts that could be shared by multiple installations or even by multiple services.

- Installation services (sometimes referred to by the sites as base operating support, or base operating support [BOS]-terms are used interchangeably) contracts usually include specific CPC requirements and deliverables, and the contractor must have qualified personnel on staff or must subcontract CPC efforts to qualified personnel. BOS contracts/installation services are widely used across installations because of the need for responsive services.

CPC Planning Best Practices

- Identify potential for tidal and coastal flooding

- Comply with Flood Protection requirements (UFC 2-100-01, Installation Master Planning) - "Hazard areas must be identified during the planning process. E.O. 11988 requires buildings to be constructed above the 100-year flood plain elevation 2009 changes to the IBC require the use of ASCE 24 when designing buildings in a flood hazard area"

- Identify the CPC requirement with specific recommendations

- Engage a CPC subject management expert to advise of any special requirements that should be included in the project plan and description

- Leverage corrosion prevention opportunities in the development and modification of the installations master plan and during project site selection

- Verify environmental conditions and corrosion potential associated with the selected site (tidal and coastal flooding, environmental severity, subsurface contaminants and soil corrosiveness, and prevailing winds)

- Verify proposed building height and orientation mitigates corrosion potential for facilities and structures proximate to salt water

- Identify corrosive impacts from user operations and equipment

- Industrial processes and contaminants

- Electrolytic corrosion from external currents and bonding and grounding of equipment

- Identify industrial processes and contaminants. Locate industrial area and industrial buildings to minimize the impact of chemical/pollution contaminants to adjacent buildings and structures.

- Budget for CPC Features on the DD 1391

- Special foundations and utilities protection (flood and soil contaminants/PH)

- Cathodic Protection if required

- Upgraded materials and coatings for enhance corrosion prevention for sites subjected to higher levels of environmental severity.

- Request input from the facilities manager where the project will be constructed and sustained to ensure that local environmental severity factors are considered.

- Develop the project plan, budget and associated documentation to include the specifications and standards used to provide the details of materials, processes and procedures and identify any verification required for incorporation into the QA/QC processes. Select active CPC features, such as cathodic protection, where needed.

- Plan facility projects to minimize exposure to corrosive environments. Ensure project budgets allow for corrosion prevention and control measures appropriate for the corrosiveness of the environment at the selected project site to ensure that it can reach the intended service life without extensive preventative or corrective maintenance.

- Mitigate the effects of buildings and structures located near salt water and with high environmental severity

- Relocate if possible

- Shelter building or structure with natural protection

- Reduce building height and orient to minimize salt fall exposure

- CPC requirements are often left to the assigned project manager after the project is approved for inclusion in the Request for Proposal (RFP). Good planning principles encourage planners to make certain that the appropriate CPC wording is included in project documentation and associated estimates and mission impact statements.

CPC Planning Summary

Facilities planning encompasses a broad process; it is only as detailed as the planning requirement dictates. Planning considerations for the larger projects may not include CPC unless it has a specific CPC requirement that is over and above the norm. For example, planning for an administrative building would focus on function, the number of inhabitants, and the processes that are carried out, as well as describing at a high level the building envelope and HVAC requirements. Specific coatings would be left to the architect/engineer to specify and, possibly, the contractor to select. A petroleum tank farm should clearly incorporate environmental parameters that would dictate types of coatings, cathodic protection, and containment requirements. A facility located in a highly corrosive environment, such as Guam, Hawaii or on a waterfront, would need to have CPC requirements identified in planning documents to ensure that they are appropriately scoped, designed and constructed for durability and life cycle expectations. Good planning considers all issues to assure meeting the project requirements. The associated budget must be compatible with life cycle, operational, durability and sustainability objectives. Considering and including CPC in that planning analysis makes for good results and ensures that they will be addressed in the RFP and inclusion in the subsequent design and constructed project.

Relevant Codes and Standards

Department of Defense

Unified Facilities Criteria (UFC) and Unified Facilities Guide Standard (UFGS)

- UFC 1-200-01 DoD Building Code (General Building Requirements)

- UFC 2-100-01 Installation Master Planning

- Unified Facilities Guide Specifications - Master list of UFGSs

National Association of Corrosion Engineers (NACE)

International Organization for Standardization

ADDITIONAL RESOURCES

WBDG

- Federal Facility Criteria (FFC)-Extensive electronic library of construction guide specifications, manuals, standards and many other essential criteria documents

- CPC Source - Policy Table

- Unified Master Reference List (UMRL) - Lists publications/Industry criteria referenced in UFGSs

- Corrosion Toolbox

- Corrosion Prevention and Control Checklists Tool