by Nicholas A. Silver and Wolfgang Gaebel for the Director, Corrosion Policy & Oversight (DCPO), (DASD) [Materiel Readiness]

Updated: 09-23-2021

INTRODUCTION

Within This Page

Environmental severity is defined as the corrosivity of the local environment of a given location or region. Environmental severity contributes directly to the occurrence of corrosion. The effects of corrosion and the rate at which they occur are consequences of the corrosion system, which is comprised of a material or physical system, the environment, and operational conditions. Corrosion can occur in many different forms including uniform/general, galvanic, crevice, pitting, de-alloying, intergranular, fatigue, erosion/flow-assisted, fretting, stray current, and stress corrosion cracking. The Department of Defense (DoD) designs, operates and manages a vast array of facilities in a variety of environments with varying levels of corrosivity, which makes protecting against and mitigating the effects of these corrosion mechanisms an on-going and ever-present engineering challenge. In accordance with DoDI 5000.67 , the DoD has a requirement to implement Corrosion Protection and Control throughout the life cycle of all facilities. As such, Environmental Severity Classification (ESC) could assist in the planning, design, and engineering of DoD Facilities when applied in the appropriate manner.

Description

Environmental severity is rarely uniform and can vary widely across different locations and regions. There are many factors that contribute to the severity of a given environment, including climatological, geographical, biological, and human. These factors can vary within a given location and can change year-to-year based upon usage, natural weather patterns, and economic development. The specific environmental factors considered by the environmental severity characterization methods evaluated by this study, either directly or indirectly, can include temperature, humidity/atmospheric moisture, precipitation, salinity, topography, UV, winds, chloride deposition, sulfur dioxide deposition and other pollutants. Recognizing the effects these factors have on the corrosion susceptibility of facilities and prioritizing the mitigation of these effects can significantly impact not only life cycle cost but readiness and safety as well. Characterization of environmental severity for DoD locations and operational environments can aid in minimizing these risks.

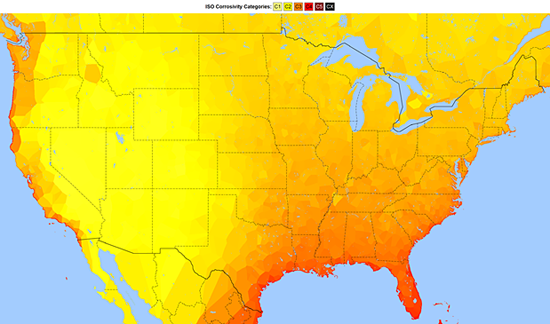

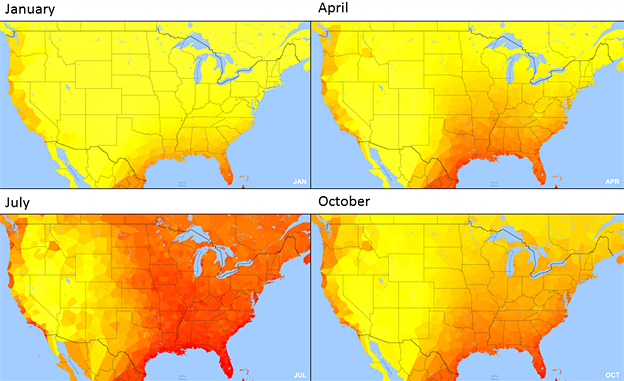

Several environmental severity characterization methods and corrosion monitoring and evaluation efforts have been undertaken over the years. After evaluating the options, it was determined that the ISO Corrosivity method and ESC factors could potentially provide the best basis for evaluating environmental severity for facilities. Figure 1 below shows a corrosivity heat map of the U.S using the ISO Corrosivity and ESC factors methodology. This map was calculated using five years of National Oceanic and Atmospheric Administration (NOAA) environmental data (2010 - 2014).

Classification of environmental severity, using ESC factors and ISO Corrosivity classification, may provide designers, planners and decision makers with tools for making more informed decisions based on their atmospheric environments, such as selection of materials and systems that have appropriate levels of durability in that environment. The preferred methods for determining ISO Categories are:

- Corrosivity Determination based on one-year corrosion mass loss or penetration of standard specimen. When one-year corrosion, mass loss, or corrosion penetration data is available, this method should be used as it provides a direct corrosion measurement. ISO Corrosivity Categories determined for various locations using this method can be found in Appendix C of the Facilities ESC Study report. Specifics regarding this method can be found in ISO 9223, section 7.

- Calculated ISO Categories using the ICCET, which is based on detailed environmental information. Pre-calculated ISO Categories for DoD locations using the ICCET can be found in Appendix D of the Facilities ESC Study report. Specifics regarding this method can be found in section 5.3 of the Facilities ESC Study report.

For the majority of DoD sites that do not have the direct corrosion data necessary for Corrosivity Determination, the ICCET provides a quick and easy baseline severity based on best available data without having to do on site long term corrosion testing. This tool helps bypass the need to collect the necessary environmental data and performing the calculations separately. The ICCET can be found in the WBDG Tools section.

It is important to note that, while environmental severity classification may be a useful tool for the characterization of local environments, it is not indicative of absolute corrosion potential or total environmental corrosivity. No classification method can accurately cover all situations that occur in natural environments and service conditions. In addition, the actual environment that affects a specific material or system correlates directly to the conditions of the micro-environment that it experiences (the "local environment" that occurs on the surface of the material or system), which can vary even over small distances.

Figure 1 - U.S. ICCET Corrosivity Heat Map

Source: Map Data© 2016 Google, INEGI

For full versions of this image, visit the Corrosion Toolbox on the WBDG.

It is important to note that classification of the corrosivity of atmospheres can be a useful tool for the characterization of environmental severity of local environments, but it is not indicative of absolute corrosion potential or total environmental corrosivity. No classification method can accurately cover all situations that occur in natural environments and service conditions. The actual environment that affects a specific material or system correlates directly to the conditions of the "micro-environment" that it experiences (the "local environment" that occurs on the surface of the material or system), which can vary even over small distances. Micro-environments with differing environmental severity can occur within a given environment or zone.

In addition, environmental severity classification cannot account for some component, service, or situational specific corrosion issues that can occur regardless of the local environmental severity category. This includes crevices and water traps that contribute to prolonged surface wetness (crevice corrosion), galvanic connections, corrosion of interior components (condensation on piping and other surfaces or improper venting of corrosive particulates in industrial applications), and building orientations or design geometries that result in specific localized areas of corrosion. Environmental severity classification is also specific to atmospheric corrosion (between the thermosphere and the surface of the earth, but generally focusing on the troposphere where weather occurs and where facilities are located) and does not account for subterranean or submerged environmental situations, such as soil corrosivity and submerged structures.

ISO Corrosivity Classification Standards

The ISO Corrosivity Classification method is contained in ISO 9223:2012. This method consists of corrosivity categories defined by first-year corrosion effects on standard specimens as specified in ISO 9226. ISO Corrosivity Categories can be assessed in terms of the most significant atmospheric factors that influence the corrosion of metals and alloys. In this sense, ISO Corrosivity Categories characterize the corrosivity of the atmospheric environment and can provide a basis for the selection of materials and systems that are subject to the demands of the specific application and its required service life.

The ISO Corrosivity Classification table defines six corrosivity categories (C1 - very low, C2 - low, C3 - medium, C4 - high, C5 - very high, CX - extreme) based on one-year corrosion mass loss or penetration of steel, zinc, copper, and aluminum coupons. It is important to note that CX generally covers the most extreme environments - usually offshore environments. Corrosivity Category determination based on corrosion rate measurement of standard specimens table can be found in ISO 9223, Table 2. Examples of typical environments and their relation to corrosivity categories can be found in ISO 9223, Annex C.

The ISO Corrosivity Category method is preferable for a variety of reasons, including current DoD policy mandating use of Non-Government Standards (NGOs), correlation to other environmental severity methods, applicability of existing metal corrosion data, and applicability and correlation of available and easily accessible environmental data. DoD standards are mandated to use NGOs to the extent possible by the Defense Standardization Program, pursuant to DoDI 4120.24 Defense Standardization Program (DSP) .

ESC Factors - ISO Corrosivity Category Estimation Tool (ICCET)

The ISO Corrosivity Classification method was developed using data obtained from the ISOCORRAG International Atmospheric Exposure Program, in which one-year corrosion rate samples were exposed at 53 sites in 13 different countries. In addition, the DoD also has employed corrosion monitoring efforts over the years and has obtained similar one-year corrosion rate data at DoD locations around the world. From these efforts, a hybrid tool using existing modeling and mapping solutions was developed called the ISO Corrosivity Category Estimation Tool (ICCET).

The ICCET is a web-based, automated tool that combines corrosion estimation models with National Oceanic and Atmospheric Administration (NOAA) environmental data and mapping technology to provide a quick, easy-to-use method for estimating ISO Corrosivity Categories for given locations. This method simply provides an easy, alternate method for estimating ISO Corrosivity Categories. This tool and the methodology on which it was developed is referred to as ESC Factors.

The ICCET uses three estimation models that were developed to estimate corrosion mass loss and ISO corrosivity categories. Each model is based on a separate salinity value, a measure of relative distance to saltwater:

- Model 1: less than or equal to 1 mile

- Model 2: greater than one mile but less than or equal to 6 miles

- Model 3: greater than 6 miles

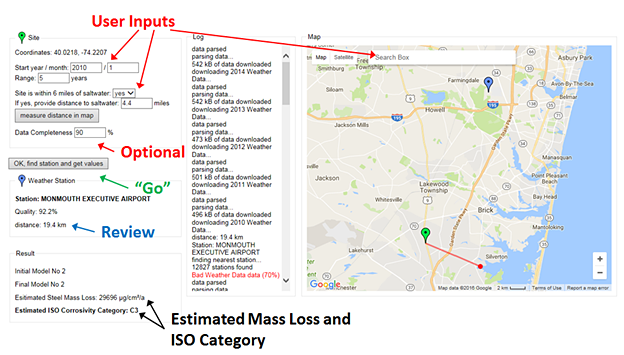

The ICCET is designed to be straightforward and easy to use. The user simply inputs:

- Location (via google map interface)

- Starting year/month and range (in years, at least five years is suggested)

- Salinity (> six miles, between six miles and one mile, and less than one mile)

- Data completeness (optional, default is 90%)

Figure 2 below shows an example of the ICCET Interface.

Figure 2 - ICCET Interface

Source: ICCET

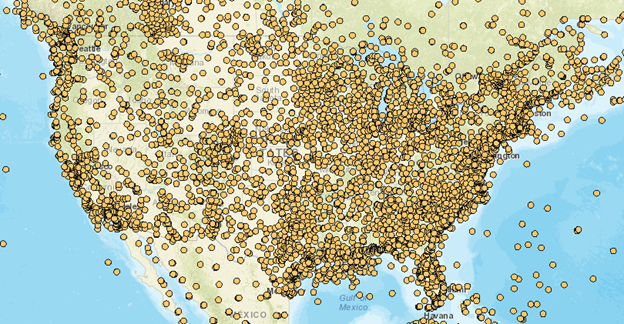

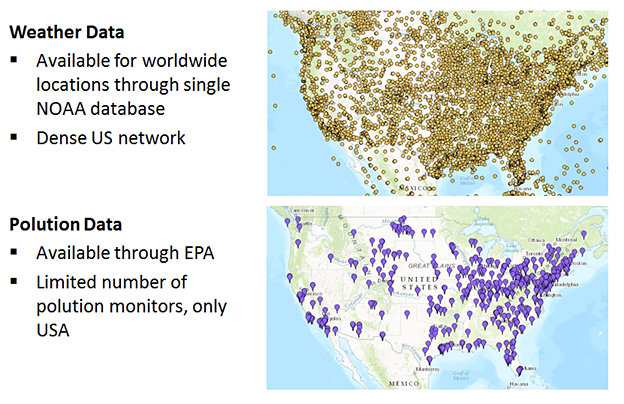

After all desired parameters have been entered, the user clicks the "OK, find station and get values" button. Using the NOAA database and Google Maps API, the ICCET automatically finds the nearest weather station and evaluates the weather data for completeness within the given data completeness range. If the data is not sufficient, the tool will find the next nearest weather station. Figure 3 below shows the density of weather stations of for which hourly environmental data exists on the NOAA National Centers for Environmental Information (NCEI) database used by the ICCET.

Figure 3 - NOAA NCEI Hourly Observational Data Map

Source: NCDC-NOAA

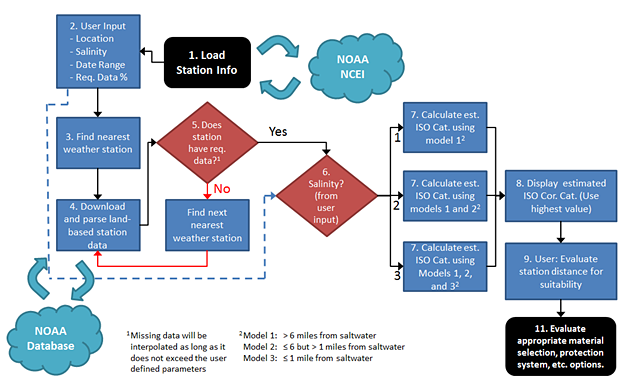

Once a suitable station is identified, the tool calculates the estimated ISO Corrosivity Category using the user-defined salinity and displays it in the results box. Figure 4 below shows the algorithm used by the ICCET to calculate estimated ISO Corrosivity Categories.

Figure 4 - ICCET Process/Algorithm

Source: Facilities Environmental Severity Classification Study, 16 February 2017

The ICCET uses hourly environmental data to perform the calculations. The environmental factors that affect the rate of corrosion change constantly throughout the year. Because of this, it is necessary to use the most detailed and up-to-date environmental data available. As noted by Dr. Dave Rose in his Cumulative Corrosion Damage Model PhD Dissertation, the "principle advantage of using hourly data/calculations is that the effects of diurnal and seasonal temperature cycles and related changes to relative humidity are explicitly considered." Figure 5 below shows seasonal variation in corrosivity.

Figure 5 - Environmental Severity Seasonal Variation (10 Year Monthly Avg. 2007-2016)

Source: Map Data© 2016 Google, INEGI

Classifying Environmental Severity for DoD Locations

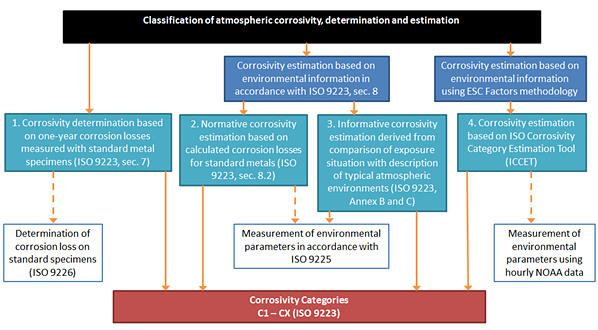

With the ISO Corrosivity Standards and the ICCET, four methods for calculating or estimating ISO Corrosivity Categories were identified using ISO and ESC methodology - three of which are contained within ISO 9223:2012:

- Corrosivity Determination:

- Based on one-year corrosion mass loss or penetration of standard specimen. ISO Corrosivity Categories determined for various locations using this method can be found in Appendix C of the Facilities Environmental Severity Classification (ESC) Study report. Specifics regarding this method can be found in ISO 9223, section 7. Appendix D provides a quick view of the results of those calculations by installation.

- Normative Corrosivity Estimation:

- Based on calculated corrosion losses for standard metals, dose-response function using environmental factors to estimate one-year corrosion mass loss/penetration.

- Informative Corrosivity Estimation:

- Based on comparison of exposure situations with descriptions of typical atmospheric environments, uses tables in Annex B and C of ISO 9223 to determine ISO corrosivity category.

- ISO Corrosivity Category Estimation Tool (ICCET)

- A new classification tool developed as part of this study. Uses the methodology provided in the ISO Corrosivity Classification standards. Pre-calculated ISO Categories for DoD locations using the ICCET can be found in Appendix D of the Facilities ESC Study report. Specifics regarding this method can be found in section 5.3 of the Facilities ESC Study report.

Figure 6 below shows the relationship between the ISO classification methods and the ICCET.

Figure 6 - Methods for Determining and Estimating ISO Categories

Source: Facilities Environmental Severity Classification Study, 16 February 2017

The preferred methods for identifying ISO Corrosivity Categories are Corrosivity Determination (option 1) and the ICCET (option 4). The Corrosivity Determination method is considered measured ISO Corrosivity Category classification as it is directly based on of one-year corrosion mass loss values. At present, one-year mass loss data suitable for application with the ISO Corrosivity Classification method is only available for around ~152 locations. This method should be used when available, as it provides a direct corrosion measurement. The ICCET tool is considered calculated ISO Corrosivity Category Determination. This tool can be used for locations that do not have direct one-year corrosion measurements, or at locations where users would like to identify an ISO Corrosivity Category at a different part of a large installation that may span more than one environmental severity category. To access the ICCET tool, visit the Tools Section of the WBDG.

Limitations of Environmental Severity Classification

The atmospheric environment itself is a variable that constantly changes with time and condition. Classification of environmental severity provides designers, planners and decision makers with tools for making more informed decisions based on their respective atmospheric environment, but cannot provide a one-stop shop for assessing absolute corrosion potential or corrosive attack. Below are some of issues and gaps faced by environmental severity characterization methods:

- No method can cover all situations that occur in natural environments and service conditions. None of the available methods establish severity indices for all of the materials and components used in DoD weapon systems and facilities (e.g., metals and alloys degrade differently than electrical components when exposed to the same environmental stressors).

- The rate of corrosion for metals and alloys exposed in the atmospheric environment is not always consistent with the time of exposure. Over time, the surface profile of a material and the accumulation of corrosion product changes.

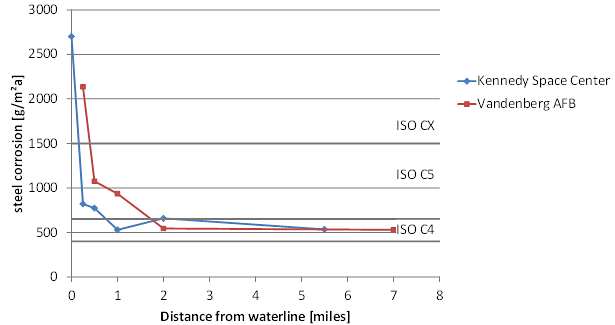

- Application in locations with high corrosivity gradients: Environmental severity can vary within locations with high corrosivity gradients and micro-climates (see figure 7 below, based on similar image from Battelle report). This is particularly true for sites located near large bodies of salt water (i.e., high salinity zone). In some situations, a DoD installation may be large enough to fit into more than one ISO Category. The environment that affects a specific material or system correlates directly to the conditions of the micro-environment that it actually experiences (the "local environment" that occurs on the surface of the material or system).

Figure 7 - Corrosion at Various Distances at KSC and Vandenberg

Source: Facilities Environmental Severity Classification Study, 16 February 2017

- Lifetime prediction of corrosion damage from atmospheric corrosivity is possible, but it is limited by the fact that the environment itself is a variable that constantly changes with time and condition. While the principles of thermodynamics and corrosion kinetics (e.g., Pourbaix Diagrams) can be employed to evaluate the theoretical activity of a given metal or alloy in a corrosion situation, the total chemical make-up of the environment in which the reaction is occurring must be known. At present, this is not possible on a large scale outside of laboratory testing or sites with active environmental or corrosion monitoring solutions. Estimation of lifetime corrosion damage can be accomplished but one must consider that these methods provide only a broad estimation of corrosion over periods of time for specific materials.

- Availability and fidelity of corrosion, weather, and cost data: One of the biggest issues related to environmental severity classification efforts is availability and fidelity of data. Currently, one-year mass loss data suitable for use in ISO only around ~152 locations. In addition, pollution and atmospheric contaminate monitoring solutions only exist for a relatively small number of locations (see figure 8 below).

Figure 8 - Comparing Weather and Pollution Data Availability

Source: Top: Map Data: NOAA; Bottom: Map Data: ArcGIS, EPA

- Variance in weather/climate year-to-year: Environmental factors, such as average temperature, relative humidity, precipitation, wind, can vary month-to-month and year-to-year. Visit the Corrosion Toolbox on the WBDG to see animated maps showing how corrosivity in the U.S. varies over time the ICCET model.

- Variance in weather data gathering methods and equipment: Although there are standard methods for gathering environmental data, not all weather monitoring stations use exactly the same methods, tools, and sensors for gathering weather data.

- Weather station equipment accuracy and calibration: In addition to the above, the equipment, tools, and sensors used by weather monitoring stations must be regularly maintained and calibrated to ensure accuracy. Currently, there is no clear way to thoroughly evaluate this for every station. The NOAA data is considered trustworthy and suitable for use in environmental severity characterization.

Additional Resources

Department of Defense

- DoD Instruction 5000.67 Prevention and Mitigation of Corrosion on DoD Military Equipment and Infrastructure, February 1, 2010

International Organization for Standardization (ISO)

- ISO 9223:2012 Corrosion of metals and alloys - Corrosivity of atmospheres - Classification, determination and estimation, February 1, 2012

- ISO 9226:2012 Corrosion of metals and alloys - Corrosivity of atmospheres - Determination of corrosion rate of standard specimens for the evaluation of corrosivity, February 1, 2012

- ISO/TC 156/WG4 ISOCORRAG International Atmospheric Exposure Program: Summary of Results, Dagmar Knotkova, Katerina Kreislova, and Sheldon W. Dean, Jr., May, 2010

Publications

- A Cumulative Damage Approach to Modeling Atmospheric Corrosion of Steel, Dissertation, University of Dayton, David H. Rose, December, 2014

- Facilities Environmental Severity Classification Study Report, Leidos, February 16, 2017

- Appendix D: Facilities Environmental Severity Classification Study, Supplemental ICCET Master Installation List, (Updated 24 August 2018)