Overview

Within This Page

Wet Laboratory space types are defined as laboratories where chemicals, drugs, or other material or biological matter are tested and analyzed requiring water, direct ventilation, and specialized piped utilities. Wet Laboratory space types do not include biohazards in Levels BL-2, BL-3, and BL-4 as defined by the 2007 NIH/CDC guideline "Biosafety in Microbiological and Biomedical Laboratories (BMBL) 5th Edition". The Wet Laboratory space types are typically located within a building specifically designed to house them (see WBDG Research Facilities). Offices, General Storage, and Warehouse space types associated with laboratories are covered in their own respective pages.

Clients are pushing project design teams to create laboratories that are responsive to current and future needs; that encourage interaction among scientists from various disciplines; that help recruit and retain qualified scientists; and that facilitates partnerships and development. As such, a separate WBDG Resource Page on Trends in Lab Design elaborates on this model of laboratory design.

One of the state-of-the-art wet laboratories at the Michigan Biomedical Research Laboratory Building, Department of Veterans Affairs. Each lab is used for a variety of medical research, including biomedical, clinical, and animal.

Photo Credit: U.S. Department of Veterans Affairs

Space Attributes

Wet Laboratory space types are unique in that they must accommodate simultaneous and separate ventilation and utility connections at individual lab modules to ensure both the reliability and accuracy of results as well as occupant safety throughout the space. Typical features of wet laboratory space types include the list of applicable design objectives elements as outlined below. For a complete list and definitions of the design objectives within the context of whole building design, click on the titles below.

Accessible

Any new lab project must consider ABA/Section 504/ADA compliance, the 2010 ADA Standards for Accessible Design published by the Department of Justice, and any state or local accessibility guidelines that may apply. The following are primary considerations for accessible design in laboratories:

- Provide some adaptable furniture systems and adjustable-height work surfaces to accommodate people in wheelchairs.

- Provide one ADA fume hood in each lab. An ADA hood is designed with a sash that opens vertically and horizontally.

- Provide one ADA height (34 in.) sink for each lab.

- Provide one ADA workstation/write-up area in each lab.

- Choose emergency shower handles that can be pushed up to stop the flow. Install pullout shelves in base cabinets.

- Install a lightweight fire extinguisher within reach of a handicapped workstation.

The new Accessible Biomedical Immersion Laboratory at Purdue University includes a wet lab and will utilize flexible space in the Discovery Learning Research Center.

Photo courtesy of Purdue University. Photo Credit: Andrew Hancock

Aesthetics

- Surfaces: Resilient surfaces are an integral part of the Wet Laboratory space type design. Use epoxy paint for lab walls and monolithic, seamless, chemical-resistant vinyl flooring with integral coved base and mylar finish.

Functional / Operational

-

Separate Laboratory Modules: A Wet Lab space is typically divided into separate laboratory modules that contain individually controlled connections to HVAC, utilities and safety devices. Modules are defined spatially by floor-to-ceiling structural slab with under-floor plenum divider.

-

Constant and Reliable HVAC: As some equipment and experiments are temperature- and humidity-sensitive, constant conditions are required in Wet Laboratory spaces to ensure that equipment can perform properly and that experiments produce accurate results. Laboratories are usually supplied with variable volume, terminal reheat system with pre-filters and after-filters for 90% efficiency. In general, laboratory spaces have positive pressure relative to other spaces with no return air from the laboratory to the other spaces. For more information, see WBDG High-Performance HVAC.

-

Dust Control: Just as experiments and equipment may be sensitive to changes in temperature and humidity, so might they be to dust and other foreign particulates. For more information, see WBDG Air Barrier Systems in Buildings and Air Decontamination.

-

Gas/Utility Services: Utility connections in Wet Laboratory space types can include vacuum, pneumatic supply, natural gas, O2 and CO2, and distilled water. The fittings and connections for each module are connected to the building distribution system for six nominal piping systems.

-

Fume Hoods: Design Wet Laboratory space types to accommodate one 6'-0" chemical fume hood for each laboratory module, and provide direct 100% exhaust. It is also typical of this space type to include an acid and corrosives vented storage cabinet located under the fume hood, as well storage for emergency equipment.

-

Laboratory Occupancy: Occupancy Group Classification for Wet Laboratory is B2, Sprinkler protected construction, as per IBC, with a GSA Acoustical Class C1 for enclosed spaces and Class C2 for open spaces.

Secure / Safe

-

Design the lab to meet requirements to withstand man-made and natural hazards to optimize occupant safety and prevent loss of resources.

- Provide a security system with one or more of the following attributes:

- Some means of access control, often arranged in layers within the building

- A computerized security management system (SMS)

- Special door hardware locksets or devices that function in unison with the SMS

- A means of visually monitoring sensitive or secure areas.

-

Install a biological safety cabinet (BSC) to allow work with harmful disease agents or infected tissues without risk of infection.

-

Fire and Life Safety: All Laboratory spaces should contain a hand-held chemical emergency fire extinguisher in an emergency equipment cabinet. There is generally one fire alarm pull station by each egress point and an audible and visible (strobe) alarm in each occupiable space (not including closets, storage rooms, or coat racks). Also include toxic gas monitors in each lab module and a gas storage area with audio and visual (strobe) alarms both inside and outside the lab. Eyewash and deluge shower should be located at each module quad. For more information, see WBDG Security and Safety in Laboratories.

Sustainable

- Incorporate energy and water efficient laboratory equipment and technology into the space.

- Use high-efficiency lighting throughout the space.

- Design with certified environmentally-sustainable wood, recycled/recyclable materials, and other green building materials.

- Provide natural daylighting and healthy indoor air quality.

- For information on sustainable design in laboratories, see WBDG Sustainable Laboratory Design and Using LEED® on Laboratory Projects.

Example Program

The following program is representative of Wet Laboratory space types.

-

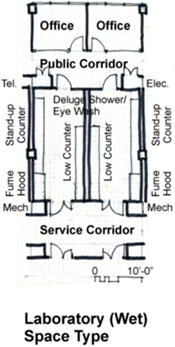

A lab planning module of 12' wide by 24' long, with utility and service closets extending 3' beyond at each end; the 12' width allows 24" deep counters along each side with 24" seating zones in front of each counter and a 36" walkway down the middle of the module and a 1'- 0" chase between modules

-

The lab modules are served by a 5' wide staff corridor on the outside, and a double loaded service corridor 6' wide on the inside

-

The 48' building centerline-to-glass planning module allows a 10' wide band of office, conference, or other support space along the building perimeter

-

The planning module fits within a 24' by 32' column bay, which allows two modules to be joined to form a 24' by 24' lab suite.

Example Plans

The following diagram is representative of typical tenant plans.

Example Construction Criteria

For GSA, the unit costs for Wet Laboratory space types are based on the construction quality and design features in the following table . This information is based on GSA's benchmark interpretation and could be different for other owners. Revolving darkroom doors, clean room ratings, additional exhaust fume hood systems, stable structure and vibration control, interstitial service plenum with walk-on or structured ceiling deck, shielded space, clean power, and additional piping systems including filtered chilled water typical of wet laboratories are not included in the table.

Relevant Codes and Standards

The following agencies and organizations have developed codes and standards affecting the design of research laboratories, including those containing dry labs. Note that the codes and standards are minimum requirements. Architects, engineers, and consultants should consider exceeding the applicable requirements whenever possible:

- 29 CFR 1910.1450: OSHA—Occupational Exposures to Hazardous Chemicals in Laboratories

- UFGS 11 53 00 Laboratory Equipment and Fumehoods

ASHRAE (American Society of Heating, Refrigeration, and Air Conditioning Engineers)

- ASHRAE 110 Method of Testing Performance of Laboratory Fume Hoods

- ASHRAE Handbook—HVAC Applications, Chapter 16, Laboratories

- ASHRAE Laboratory Design Guide

Department of Veterans Affairs

- VA 11 53 13 Laboratory Fume Hoods

- VA 11 53 61 Custom Fabricated Laboratory Equipment

- VA 22 62 00 Vacuum Systems for Laboratory and Healthcare Facilities

- VA 22 63 00 Gas Systems for Laboratory and Healthcare Facilities

General Services Administration

National Institutes of Health

- Biosafety in Microbiological and Biomedical Laboratories (BMBL) 5th Edition, December 2009.

- NIH Design Requirements Manual, 2016.

Additional Resources

Publications

- Architectural Graphic Standards, 12th Edition by The American Institute of Architects, Dennis J. Hall. New York, NY: John Wiley & Sons, Inc., 2016.

- Building Type Basics for Research Laboratories, 2nd Edition by Daniel Watch. New York: John Wiley & Sons, Inc., 2008. ISBN# 978-0-470-16333-7.

- CRC Handbook of Laboratory Safety, 5th ed. by A. Keith Furr. Boca Raton, FL: CRC Press, 2000.

- Design and Planning of Research and Clinical Laboratory Facilities by Leonard Mayer. New York, NY: John Wiley & Sons, Inc., 1995.

- Design for Research: Principals of Laboratory Architecture by Susan Braybrooke. New York, NY: John Wiley & Sons, Inc., 1993.

- Guidelines for Laboratory Design: Health and Safety Considerations, 4th Edition by Louis J. DiBerardinis, et al. New York, NY: John Wiley & Sons, Inc., 2013.

- Handbook of Facilities Planning, Vol. 1: Laboratory Facilities by Theodorus Ruys. New York, NY: Van Nostrand Reinhold, 1990.

- Handbook of Facilities Planning, Vol. 2: Laboratory Animal Facilities by Theodorus Ruys. New York: Van Nostrand Reinhold, 1991.

- Laboratories, A Briefing and Design Guide by Walter Hain. London, UK: E & FN Spon, 1995.

- Laboratory by Earl Walls Associates. May 2000.

- Laboratory Design from the Editors of R&D Magazine.

- Laboratory Design, Construction, and Renovation: Participants, Process, and Product by National Research Council, Committee on Design, Construction, and Renovation of Laboratory Facilities. Washington, DC: National Academy Press, 2000.

- Research Laboratory Design Guide by the U.S. Department of Veterans Affairs Office of Research and Development and the Facilities Quality Office. September 1995.

Others

- GSA Sustainable Facilities Tool (SFTool)—SFTool's immersive virtual environment addresses all your sustainability planning, designing and procurement needs.

- Laboratories for the 21st Century (Labs21)—Sponsored by the U.S. Environmental Protection Agency and the U.S. Department of Energy, Labs21 is a voluntary program dedicated to improving the environmental performance of U.S. laboratories.