Overview

Within This Page

The Firing Range space types are special indoor facilities used to train and certify federal law enforcement personnel in the use of handguns, shotguns, rifles, etc. Firing Range space types include backstops, shooting booths or firing points/positions, target carrier systems, firing range control centers, spaces related to the use, cleaning, and storage of firearms—which may require special ballistic, hazardous material, and security measures—and toilet and shower facilities.

Indoor firing range

Space Attributes

The four main considerations for indoor ranges are shooter needs, type of shooting activity, number of firing points, and number of users. The design, operation, and maintenance of indoor Firing Ranges also require consideration of a number of safety and health factors. For example, ammunitions contain explosives and other hazardous components, such as lead. Adequate volume and direction of air movement are necessary to avoid inhalation of health hazardous lead fumes and dust and carbon monoxide released during firing. In addition, metal fragments from spent bullets must be controlled to avoid ricochets in the direction of shooters. Acoustical controls must be installed to protect firing range employees and users from hearing loss due to hazardous noise levels created by discharging weapons. Typical features of firing range space types include the list of applicable design objectives elements as outlined below. For a complete list and definitions of the design objectives within the context of whole building design, click on the titles below.

Officers participating in a close target range training.

Functional / Operational

- Occupancy: Occupancy Group Classification is Storage Group S Incidental Use in Group A, B, E, I, M, or R Occupancy Classification, with sprinklered Type IB construction and separation from other occupancies by 2–hour partitions.

- Ventilation and Lead Exposure Mitigation: When guns are loaded with lead ammunition and fired at close range, they release lead vapor and lead fumes as well as lead dust and other toxins. The ventilation system must control exposure to lead in accordance with 29 CFR 1910.1025, Lead Exposure. The supply and exhaust air system is critical to the operation of an indoor range and the health of building inhabitants. The design must include a positive exhaust system for removal of airborne lead. A slight negative air pressure must be maintained on the range, which can be achieved by exhausting typically 3 to 7 percent more air than is supplied. The optimum air supply across the firing line is 75 FPM with a minimum acceptable airflow of 50 FPM with airflow maintained at 2-30 FPM at a point halfway between the firing line and the bullet trap. Supply and exhaust fan systems must have control interlocks to ensure simultaneous operation. All doors into the negative pressure area must have air locks. Armories are typically designed to have 15-minute Class M emergency vault ventilators and ventilator ports per UL 680 Emergency Vault Ventilators and Ports and allow for the supply of 10 CFM of outside air per 100 SF. A ventilator port provides a minimum of 2 SF of openings in case of power failure. Lead sensors are recommended at supply ducts in adjoining spaces to assure the ventilation systems are working correctly. Typically, 100% exhaust is provided from firing lane areas, ammunition storage areas, and weapons cleaning areas. For more information on air decontamination strategies, see WBDG Air Decontamination.

- Noise Exposure Mitigation: Noise reduction in the range, and noise transmission out of the range, are different design considerations. Mass and limpness/flexibility are two desirable attributes for a sound transmission barrier. Unpainted heavy masonry walls provide mass. Absorptive acoustical surfacing will reduce the noise level in the range but will have little effect on the transmission outside the range. Noise levels in the range should not exceed 85 decibels, and should be considerably less to improve communication between shooters and the range official. Conventional acoustical treatment can be used on surfaces behind the firing line.

- Special Lighting: Energy-efficient light fixtures should be used to provide ambient and targeted lighting in the Firing Range. Fluorescent fixtures should have VDT-compatible parabolic lenses to concentrate light on the horizontal plane and reduce glare on wall surfaces. Lights are controlled by a firing range control system to vary lighting schemes for different shooting and emergency situations. Light baffles shall protect all lights within 40' downrange of the firing line.

- Communication Systems: Provide a two-way intercom communication system from each shooting booth to the range master with a visual call indicator light.

Secure / Safe

- Protective Construction: Materials—typically steel, plywood, and concrete—used for sidewalls, baffles, overhead containment, bullet traps, and other areas where a bullet could impact, must ensure that the bullet is deflected downrange and not towards the firing line. Ricochet control must be considered when positioning brackets used for baffles, positioning bolt heads, and selecting protective construction. For example, to prevent ricochets and trap bullets, bullet backstops made of core-filled CMU with sacrificial cladding and with no openings in the zone directly behind the firing lanes are provided. Shields at all non-ballistic walls and canopies are typically constructed of 1/4"; steel plate with 1/2"; sacrificial plywood cladding. Range floor construction is generally 8"; thick reinforced concrete with 1/4"; slope per foot from firing line to target line with a secondary slab located on neoprene cushioning.

- Personnel Safety Features, Signage: Hazard and caution signage are installed at suite entrance; and room identification signage is mounted beside the door with ADAAG compliant tactile Braille signage modules. The gun cleaning area is equipped with an eyewash station. A range alarm system, to notify users that an open door unsafe condition exists, is provided.

Typical sign denoting hazard within firing range.

Sustainable

- Air Quality: The optimum air supply across the firing line is 75 FPM with a minimum acceptable airflow of 50 FPM; maintain airflow at 2–30 FPM at a point halfway between the firing line and the bullet trap. Minimize dust by exhausting pre-filtering auto-advance rolling filter with an average synthetic dust arrestance of 83% and HEPA or equivalent filter.

- Walls: Use Low or No-VOC semi-gloss enamel paint with vinyl cove base.

- 29 CFR 1910.1025, Lead Exposure

- Department of Justice, Immigration and Naturalization Service/National Firearms Unit, Firing Range Design Standard

- PBS-P100 Facilities Standards for the Public Buildings Service, GSA, July 2018.

- ICC IBC International Building Code

- Navy Environmental Health Center Technical Manual NEHC-TM IH 6290.99-10 Rev 1, Indoor Firing Ranges Industrial Hygiene Technical Guide , May 2002.

- National Park Service, Managing Firing Range Waste

- National Institute for Occupational Safety and Health (NIOSH) Technical Information #76-130, Lead Exposure and Design Considerations for Indoor Firing Ranges. NTIS #PB266-426.

- U.S. Air Force, ETL 11-18 Small Arms Range Design and Construction

- U.S. Army, ER 210-3-2 Army Range Programs

- U.S. Department of Energy, Office of Health, Safety and Security, Range Design Criteria , June 2012.

- U.S. Navy, MIL-HDBK-1027/3B Range Facilities and Miscellaneous Training Facilities Other Than Buildings

- National Shooting Sports Foundation—Provides firing range facility information on the web site, under Shooting > Resources for Ranges.

Example Program

The following building program is representative of Firing Range space types.

FIRING RANGE

| Description Tenant Occupiable Areas |

Qty. | SF Each | Space Req'd. | Sum Actual SF | Tenant Usable Factor | Tenant USF |

|---|---|---|---|---|---|---|

| Range | 5,594 | |||||

| Bullet Stop | 8 | 90 | 720 | |||

| Firing Lane | 8 | 337.5 | 2,700 | |||

| Shooting Line | 8 | 45 | 360 | |||

| Scoring Tables | 2 | 90 | 180 | |||

| Work Bench | 8 | 22.5 | 180 | |||

| Range Control | 1 | 150 | 150 | |||

| Cleaning Room | 8 | 25 | 200 | |||

| Storage | 1 | 300 | 300 | |||

| Mechanical | 1 | 300 | 300 | |||

| Male Staff Toilet | 1 | 60 | 60 | |||

| Male Staff Showers | 1 | 20 | 20 | |||

| Male Staff Lockers | 1 | 112 | 112 | |||

| Female Staff Toilet | 1 | 60 | 60 | |||

| Female Staff Showers | 1 | 20 | 20 | |||

| Female Staff Lockers | 1 | 112 | 112 | |||

| Housekeeping | 1 | 120 | 120 | |||

| Tenant Suite | 5,594 | 5,594 | 1.10 | 6,143 | ||

| Tenant Usable Areas | 6,143 |

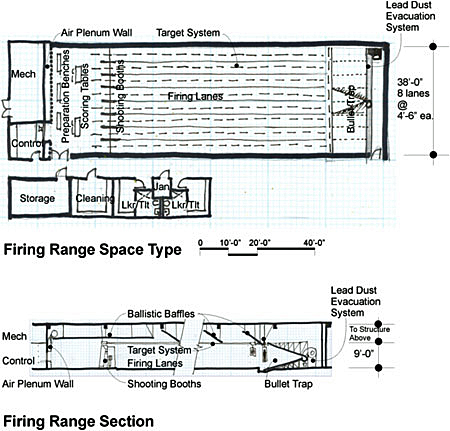

Example Plans

The following diagrams are representative of typical tenant plans.

Example Construction Criteria

For GSA, the unit costs for firing range space types are based on the construction quality and design features in the following table . This information is based on GSA's benchmark interpretation and could be different for other owners.

Relevant Codes and Standards

The following agencies and organizations have developed codes and standards affecting the design of firing ranges. Note that the codes and standards are minimum requirements. Architects, engineers, and consultants should consider exceeding the applicable requirements whenever possible: