by Joseph C. Dean, P.E. and Steve Geusic, P.E., for the Director, Corrosion Policy & Oversight (DCPO), (DASD) [Materiel Readiness]

Updated: 10-13-2021

Introduction

Within This Page

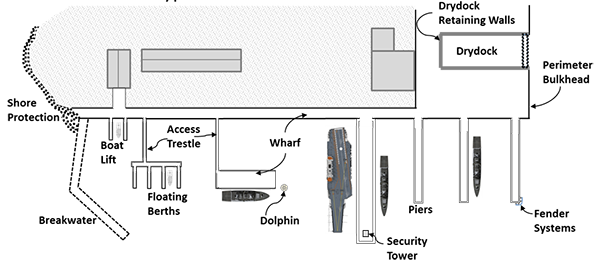

Waterfront structures such as piers and wharves serve as the transition point between seagoing vessels and the infrastructure that supports them while they are in port. Once seagoing vessels are attached to shore-based power, waste collection and other utilities support, the waterfront becomes a vibrant and dynamic city extension. Bulkheads, pilings, structural framing, decks, utility trenches, dolphins, compressed air, electric (power), steam, water, waste, and fuel lines and fender systems are additional facilities associated with waterfront and coastal structures. Because the waterfront interface is an extremely corrosive environment, a thorough understanding of that environment and the associated stresses placed on waterfront and coastal structures is vitally important to ensure mission support, safety, readiness and prevention of environmental contamination. Those corrosion factors should be reflected in planning, design, construction and sustainment processes. Photo 1 provides an aerial view of one of many configurations that can be found at a waterfront complex. The Facilities Corrosion Impacts on Operations and Missions Table provides additional insights on how these facilities can be impacted by corrosion.

Photo 1: Aerial view of a waterfront complex showing wharves, piers lay down areas, waterfront facilities, and drydock areas.

Source: MC 1st Class Christopher B. Stoltz / U.S. Navy via Reuters

Piers and wharves are defined as:

-

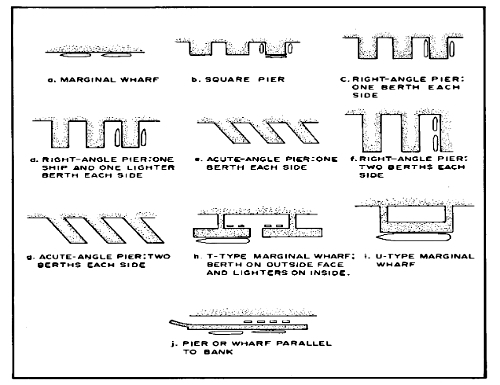

A pier is a structure that projects out from the shore into the water. A pier is oriented either perpendicular to or at an acute angle with the shore. It may be used on both sides, although only one side is sometimes used because of site conditions or because there is no need for additional berthing (Source: UFC 4-152-01 Design: Piers and Wharves) (See Figures 1 and 2).

-

A wharf is a structure oriented approximately parallel to the shore. Ships can only be moored at the offshore face of a marginal wharf. When water depths close to shore are not adequate to accommodate deep draft ships, the wharf, consisting of a platform on piles, is located offshore in deeper water and is connected to shore along its length or at one or more points by pile-supported trestles, usually at right angles to the wharf (see UFC UFC 4-152-01 Design: Piers and Wharves). A wharf is normally connected to the shore along its full length, and a retaining structure is used to contain earth or stone placed behind the wharf. This retaining structure is often referred to as the quaywall or bulkhead (Source: UFC 4-150-07 Maintenance and Operation: Maintenance of Waterfront Facilities) (see Figures 1 and 2).

Figure 1: Pier and Wharf Examples and Configurations

Source: UFC 4-150-06 Types of Berthing Layouts, Figure 5-15

Figure 2: Typical Waterfront Structures

Source: Steve Geusic, P.E.

Description

Corrosion Prevention and Control (CPC) for piers and wharves and associated supporting structures requires the interaction of many engineering disciplines such as structural, electrical, environmental, mechanical, civil, and specialty engineering areas such as cathodic protection, geotechnical, material selection, and paints and coatings. Each discipline has an essential role to play in ensuring that the waterfront infrastructure is designed, constructed and sustainable.

UFC 4-150-06 states: "The majority of materials utilized in coastal construction are quite similar to those used in dry-land construction. However, their introduction into the marine environment results in a need for the designer to expand [the] view of material degradation methods. In addition to the increased corrosive environment and possible freeze-thaw cycles, they must withstand relentless wave pounding and marine organisms that can attack most materials in a variety of ways. Primary material selection criteria are physical properties and strength, durability, adaptability, cost, availability, handling requirements, maintenance requirements, and environmental impact."

Planning and design of piers and wharves from the CPC perspective requires a thorough understanding of the many aspects of the dynamic and complex area where it is constructed and maintained. Waterfront areas are essentially industrial areas, utilizing a wide variety of infrastructure materials (concrete, wood, composites, steel, etc.) that perform a variety of missions while being exposed to a wide variety of industrial conditions, such as chemicals, and operational wear and tear.

Factors affecting waterfront facilities can include:

- Environmental Severity Classification (ESC)

- Sun exposure (ultraviolet radiation (uV))

- Salt-water impacts on materials and structures

- Geotechnical (e.g., soil corrosivity)

- Sea-level rise

- Waves, tides, freeze-thaw and ice effects

- Pressure sources (earthquakes, winds, etc.)

- Friction and material interactions

- Effective applications and usage of paints and coatings

- Ponding (water accumulation without the ability to drain)

- Marine-concrete principles to include concrete cover for reinforcing steel

- Cathodic protection system design and maintenance

- Design geometry to prevent unnecessary corrosive situations

- Design relationships of ship-to-pier and ship-to-wharf interactions to include transition structures such as fenders and camels

- Hotel service and utility connections and positioning (e.g., potable water, steam, collection of sewage and oily waste, compressed air, electricity, fuel, etc.)

- Material selection to achieve the required life cycle and service requirements

- Mooring and ship positioning creating friction and wear promoting corrosion

- Maintenance requirements and designs to make those tasks more productive

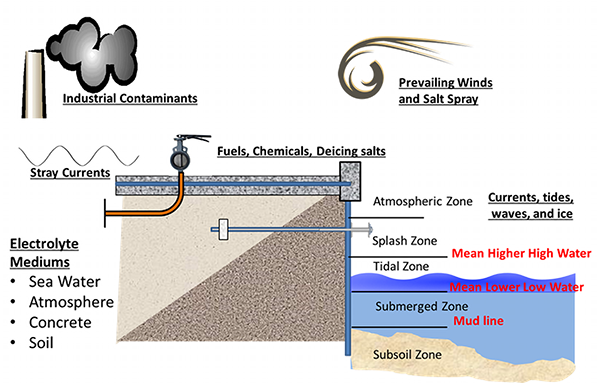

Because of the diverse environment found at the waterfront, it is not unusual to find all forms of corrosion working in concert to degrade a marine structure:

-

Uniform corrosion can often be found in the atmospheric zone.

-

Crevice corrosion due to oxygen concentration cells can be found in the submerged areas and at connections and penetrations such as sheet steel bulkhead tieback systems.

-

Erosion corrosion is commonly found at or just above the mud line on steel piling, sheet pile, and riser chains of moorings.

-

Marine Biological organisms accelerate corrosion by changing the normal environment. For example, organisms may create differential oxygen levels in the electrolyte, can create corrosive products through their metabolism or decomposition, and may remove the protective film from metal surfaces.

Figure 3 shows typical corrosion stressors of the waterfront environment and the various waterfront zones.

Figure 3: The Waterfront Environment

Source: Steve Geusic, P.E.

Recent changes to UFC 1-200-01 DoD Building Code, "Corrosion Prevention and Control," provide very specific guidance for design, construction and sustainment actions related to CPC. The UFC identifies the waterfront and coastal locations as a corrosion prone environment and requires the following: "For structures proximate or at the waterfront, in addition to atmospheric corrosion, design for the presence of hydrostatic forces, wind, salt spray, currents, tides, waves, ice, marine borers, insects, and pollution from waterfront operations." UFC 1-200-01, Appendix, ESC for DoD Locations, identifies the ESC Zone for each of the DoD Installations around the world, which then drives the types of materials and processes to be used for corrosion-prone locations. Because UFC 1-200-01 is more recent than many of the UFCs and UFGSs mentioned here, that guidance becomes especially important.

The environmental severity increases dramatically with proximity to the coastline and other saltwater sources. Since the ESC in UFC 1-200-01 represents the general UFC of the installation, it is important to insure that the ESC is representative of the severity at the project site. ESC superscripts and corresponding notes found in the Appendix A ESC Tables help to identify ESC proximity to a saltwater source. In general, if the facility or system is located on the shoreline, design for the most severe ESC.

While the following UFC and UFGS highlights list is not all-inclusive, it does contain insights into the magnitude of design, construction and maintenance of waterfront structures, especially in corrosion-prone locations. Considering and addressing these issues will assist in achieving CPC such that the design supports the mission and meets life-cycle expectations. It will also ensure that all design choices are made to account for the realities of waterfront dynamics. Environments are evolving, with more intense storms, temperature changes, and higher sea levels. Therefore, decisions on structure placements, the extent of splash-zone coverage, orientation of facilities, and material selection will have a direct impact on the extent of corrosion and CPC measures required to keep facilities operationally ready.

-

Steel may be used when protected against corrosion. Corrosion protection options for steel include concrete encasement/encapsulation, bituminous or plastic (epoxy) coatings, galvanizing, flexible membrane / tape wrappings, and weathering steels.

-

Cathodic protection. See UFC 4-152-01 and UFC 4-151-10 for additional corrosion protections for steel in the waterfront environment.

-

Concrete has proven to be the best material for pier and wharf construction, and, when properly designed and constructed are highly durable in the marine environment. (Source: UFC 4-152-01)

-

"Concrete enhanced with fly ash and corrosion inhibitors has demonstrated superior performance and should be used whenever possible. UFGS 03 31 30 Marine Concrete contains the latest developments in marine concrete." (Source: UFC 4-152-01)

-

Corrosion of prestressed concrete pile reinforcement can be controlled with "proper mix design and, extreme cases, by epoxy coating reinforcement." (Source: UFC 4-152-01)

-

Aluminum members are useful for deck-supported structures and for piping and conduit support. That said, aluminum should be electrically isolated from adjacent materials. (Source: UFC 4-152-01)

-

Fiberglass-reinforced plastics (FRP), ultra-high molecular weight (UHMW) plastics, and high-density polyethylene (HDPE) are being increasingly used in waterfront construction." (Source: UFC 4-152-01) The UFC mentions the disadvantages of composite materials which include low strength, uV light deterioration, long term durability and high cost. In non-shaded applications ensure the resins are formulated to enhance UV resistance and specify ASTM D4329 Standard Practice for Fluorescent Ultraviolet (UV) Lamp Apparatus Exposure of Plastics to specify UV performance.

-

See UFC 4-152-01 for Pile Cap design recommendations.

- For Dockside Utility Design guidance see UFC 4-150-02.

- Where salt-spray exposure is severe, add corrosion protection for hangars

- In marine environments, a Cathodic Protection System (CPS) can greatly extend the life of the submerged zones of steel waterfront structures. For buried and submerged structures, a CPS in conjunction with other protective measures such as material thickness incrementation, protective coatings and encasement is recommended for:

- Steel sheet piling bulkheads

- Steel Bearing piles for piers

- Steel fender piles for piers

- Mooring components

The splash and atmospheric zones will require reapplication of coatings and encasements for maximum system service life.

- A qualified corrosion engineer must be provided for CPS. [See the UFC for specific wording and requirements]

- Provide CPS and protective coatings for:

- Petroleum, Oils and Lubricants (POL) pipelines

- Oxygen pipelines

- Underground POL and gasoline storage tanks

- Underground hazardous substance storage tanks

- Water storage tanks

- Other systems as defined

- The UFC is very specific about qualifications of engineers and corrosion specialists engaged in the design and construction of these systems.

- Provide CPS and protective coatings for:

- Delineates specific requirements, concerns and materials selection and use where salt or brackish waters are present.

- Addresses location of collecting sewers, pump stations and utility trenches for increased functionality and reduced corrosion.

- UFC 3-570-01 Cathodic Protection and UFC 3-570-06 Operation and Maintenance: Cathodic Protection Systems

- Delineates mandatory use of CP on "new waterfront structures" as well as POL, utilities, etc.

- The Waterfront Structures section lists several areas requiring CP systems such as steel bearing piles, sheet pile bulkheads, fender piles, and submerged mooring components.

- "Active [i.e., impressed-current] cathodic systems are difficult to design, construct, and maintain properly, therefore, passive [i.e., galvanic or sacrificial-anode] systems are preferred." (Source: UFC 4-152-01)

- Requires evaluation for the use of CP on existing waterfront structures.

- The UFC provides extensive information and guidance on specific systems, locations and related information.

-

UFC 3-190-06 Protective Coatings and Paints provides guidance for coating steel waterfront structures.

- UFGS-09 97 13.26 Coating of Steel Waterfront Structures, Zero VOC, (SZC) Splash Zone Coating

- Addresses requirements for coating new or existing steel-sheet piling and other steel waterfront structures may also be used for repairing and coating aged surfaces. A coating condition survey (CCS) is required for maintenance coating designs.

- The UFGS addresses qualifications and certifications requirements for the third-party protective-coating specialist, the coating-inspection company, coating contractors, testing laboratory, individuals applying coatings, and other relevant parties.

- The remainder of the UFGS provides extensive requirements on the coating system, execution, including surface preparation and application, inspection and quality control.

- The complexity of the application of these coatings and the associated process is consistent with the dynamics of the waterfront zone and the life cycle requirements for the facility.

-

UFGS-31 62 13.20 Precast/Prestressed Concrete Piles states, "Cement type and quantity of cement required in mix design is dependent upon the environment, soil conditions, need for corrosion protection, and location of piling" and in the Reinforcing Steel section, "Minimum cover for reinforcing steel in concrete structures is dependent upon the environment, soil conditions, need for corrosion protection, and location of piling." Similar wording can be found in UFGS-31 62 13.24 Concrete Cylinder Piles.

-

UFGS-31 62 16.16 Steel H-Piles addresses CPC in the marine environment. CPC for steel H-piles includes splash zones, seawater protection, the use of coating systems, cathodic protection and steel encasement or metal jacketing.

- UFC 4-150-07 Maintenance and Operation: Maintenance of Waterfront Facilities contains many references to corrosion and the appropriate mitigating actions. A thorough inspection program that includes identification of corrosion-related issues is essential to maintaining and sustaining waterfront facilities.

- This UFC provides extensive descriptions of corrosion damage, inspection tables (see the Figures for waterline steel structures checklists), guidance for inspection of materials and facilities (e.g., quay walls) and the associated inspection report format.

- The UFC also addresses corrosion in supporting structures such as foam-filled fenders.

- In addition to inspections, the UFC provides insights into repairing corrosion damage and recommended materials for use in the waterfront zone.

- For example, the UFC recommends specific procedures for installing cathodic protection systems to protect steel sheet piles.

- This is an excellent document for design engineers for waterfront structures. Through understanding the corrosion risks and associated deterioration processes, designers will be able to mitigate potential corrosion damage, thereby extending facilities’ service life.

Photo 2: Foam-Filled Fender System (Figure 5-5 UFC 4-152-01 Foam-filled fender, concrete fender piles, steel frame and polyethylene rub strips). Also observe waterfront utilities, camels, and pier structure in this photograph.

Source: Marine Fender Systems, by T.E. Spencer, ASCE PORTS 2004

Summary

Facilities constructed and sustained in the waterfront coastal zone endure high levels of corrosion-related stresses made worse because of waves, wind, tides, temperature, and ice. In this ever-aggressive corrosion environment, designers and maintainers must be vigilant to ensure that the best materials, construction processes and sustainment practices are utilized. In addition to the piers, quay walls, bulkheads and wharves, supporting structures such as bollards, dolphins, camels and fenders must be designed to meet life-cycle and durability requirements to ensure that the entire system of fixed and movable structures acts as a unified whole to guarantee availability for the operating forces when needed.

While not all of the references under "Relevant Codes and Standards" below may include the word “corrosion” or CPC terminology, they each have several common threads:

- Environmental impacts

- Material selection

- Design and sustainment of cathodic-protection systems

- Treatments (e.g., coatings and galvanizing) of materials and structures

- Designing to withstand the hostile impacts in the coastal zone

- Sustainment actions

Waterfront structures make up a challenging area of design, construction and sustainment. They require close attention to detail and good judgment to meet durability and operational needs.

Additional Resources

Unified Facilities Criteria (UFC)

- UFC 1-200-01 DoD Building Code

- UFC 3-190-06 Protective Coatings and Paints

- UFC 3-220-01 Geotechnical Engineering

- UFC 3-250-01 Pavement Design for Roads and Parking Areas

- UFC 3-270-01 O&M Manual: Asphalt and Concrete Pavement Maintenance and Repair

- UFC 3-270-08 Pavement Maintenance Management

- UFC 3-570-01 Cathodic Protection

- UFC 3-570-06 Operation and Maintenance: Cathodic Protection Systems

- UFC 4-025-01 Security Engineering: Waterfront Security

- UFC 4-150-02 Dockside Utilities for Ship Service

- UFC 4-150-06 Military Harbors and Coastal Facilities

- UFC 4-150-07 Maintenance & Operation: Maintenance of Waterfront Facilities

- UFC 4-150-08 Inspection of Mooring Hardware

- UFC 4-150-09 Permanent Anchored Moorings Operations and Maintenance

- UFC 4-151-10 General Criteria for Waterfront Construction

- UFC 4-152-01 Piers and Wharves

- UFC 4-159-03 Design: Moorings

- MO-104.2 Specialized Underwater Waterfront Facilities Inspections

Unified Facilities Guide Specifications (UFGS)

- UFGS-03 31 29 Marine Concrete with Service Life Modeling

- UFGS-03 31 30 Marine Concrete

- UFGS-09 97 13.26 Coating of Steel Waterfront Structures, Zero Voc, Splash Zone Coating

- UFGS 26 42 13 Galvanic (Sacrificial) Anode Cathodic Protection (GACP) System

- UFGS 26 42 15 Cathodic Protection System for the Interior of Steel Water Tanks

- UFGS 26 42 17 Impressed Current Cathodic Protection (ICCP) System

- UFGS 26 42 19.10 Cathodic Protection Systems (Impressed Current) For Lock Miter Gates

- UFGS-31 62 13.20 Precast/Prestressed Concrete Piles

- UFGS-31 62 13.24 Concrete Cylinder Piles

- UFGS-31 62 16.16 Steel H-Piles

- UFGS-31 62 19 Timber Piles

- UFGS-31 62 19.13 Timber Marine Piles

- UFGS-35 59 13.14 20 Polymeric Piles

U.S. Army Corps of Engineers - Public Works Technical Bulletin (PWTB)

- PWTB 420-49-29 Operation and Maintenance of Cathodic Protection Systems

- PWTB 420-49-37 Cathodic Protection Anode Selection

U.S. Army Corps of Engineers (USACE) Engineer Manuals

American Society of Civil Engineers (ASCE)

- ASCE 7 Minimum Design Loads for Buildings and Other Structures

- MOP 129 Mooring of Ships to Piers and Wharves

International Code Council (ICC)

Whole Building Design Guide

- CPC Source – Cathodic Protection Knowledge Area

- CPC Source – Corrosion Science Knowledge Area

- CPC Source – Paints and Coatings Knowledge Area

- CPC Source – Asphalt Concrete and Portland Cement Concrete Pavements Knowledge Area

- CPC Source – Petroleum, Oil, and Lubricants (POL) Storage and Distribution Systems Knowledge Area

- CPC Source – Waterfront and Coastal Structures Knowledge Area

- CPC Source – Environmental Severity Classification (ESC)

- CPC Source – Facilities Corrosion Impacts on Operations and Mission

- Waterfront Facilities

- CPC Checklists Tool

- Corrosion Toolbox

Federal Agencies

- Federal Emergency Management Agency (FEMA)

- Maritime Administration (MARAD)

- National Oceanic and Atmospheric Administration (NOAA)

- Naval Facilities Engineering Systems Command (NAVFAC)

- U.S. Air Force Civil Engineer Center (AFCEC)

- U.S. Army Corps of Engineers (USACE)

- U.S. Geological Survey (USGS)

Organizations / Associations

- American Association of State Highway and Transportation Officials (AASHTO)

- American Society of Civil Engineers (ASCE)—Coasts, Oceans, Ports, and Rivers Institute (COPRI) [ASCE]

- Association for Materials Protection and Performance (AAMP) (NACE and SSPC)

- Master Painters Institute (MPI)

Publications

- ASCE Library

- Seismic Guidelines for Ports by S. D. Werner. Reston, VA: ASCE-TCEE, 1998.

- Wharf Design Criteria, Version 4.0 by Port of Long Beach. Long Beach, CA: POLB WDC, 2015

Tools

- Corrosion Toolbox (ICCET)

- NOAA Sea Level Rise Viewer

- NOAA Tides and Currents

- USACE Sea Level Change Curve Calculator

Training

- Corrosion Prevention of Waterfront and Coastal Structures

- Cathodic Protection Basics

- Corrosion Fundamentals

- Coating Fundamentals

- Corrosion Prevention and Control of Utilities and Buried Structures