Introduction

Within This Page

Americans spend nine out of ten hours indoors; and indoor air commonly contains higher concentrations of airborne chemical contaminants and pathogenic microbes than outdoor air. Biological and chemical terrorism, sick buildings, cruise ship disease outbreaks, toxic molds, and epidemics of asthma and allergies, all have made the issue of healthy air critical. Removing biological pathogens and toxic chemical compounds from air—air decontamination—has been a recognized need for decades and has mostly been accomplished through ventilation. Airflow and ventilation are already key factors in worker comfort, health and productivity, building design, and energy efficiency. Air security is the next frontier, and can also improve the health of the day-to-day air in a modern facility.

This Resource Page presents both the scientific fundamentals of clean air, vis-à-vis filtration and UV, and the benefits and obstacles associated with these technologies. It also briefly discusses a number of other technologies that have been offered as solutions. This Page was written to provide a general understanding of air decontamination technologies for practitioners that may be new to this field, as well as provide updated codes and resources for those who wish to gain more in depth knowledge. Since the field is in considerable flux, a number of source documents from government and professional association websites where up-to-the-minute information can be obtained are also provided.

Description

In the report "Review of Health and Productivity Gains from Better IEQ" written by William J. Fisk of the Indoor Environment Department at Lawrence Berkeley National Laboratory, increased indoor air quality could result in the following monetary savings:

- estimated potential annual savings and productivity gains of $6 billion to $14 billion from reduced respiratory diseases;

- between $2 to $4 billion savings from reduced allergies and asthma;

- $10 to $30 billion in savings from reduced sick building syndrome symptoms; and

- $20 to $160 billion can be saved from direct improvements in worker performance that are unrelated to health.

The economic and public health benefits combined with today's interest in protecting the population from weapons of mass destruction have prompted renewed interest in methods of removing infectious or allergenic microorganisms from the air we breathe in indoor environments. Active decontamination technologies such as ultraviolet light (UV) and high efficiency particulate air (HEPA) filters have previously been used for germicidal air cleansing in infectious disease wards and laboratories. However applying these decontamination processes or other experimental technologies to the high airflow ventilation systems of modern office buildings presents a new set of challenges. It requires a fundamental rethinking of many elements of HVAC design, from the location and security of air ducts, to the integrity and protection of air controls, and the organization, layout, and construction of the active decontamination components for the systems themselves.

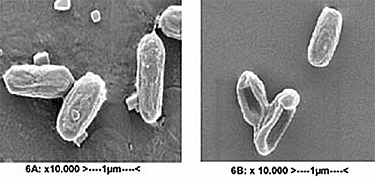

A. Air Filtration

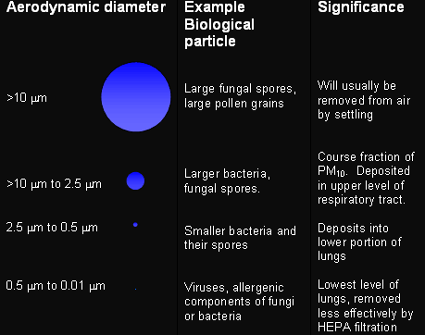

The simplest solution to disinfecting the air is to capture offending particles in a filter mesh of some kind. The development of high efficiency particulate air (HEPA) filters has made it possible to efficiently clear the air of particles down to 0.3 µm (micrometers) in size, with smaller particles captured to varying degrees. Viruses are the smallest, ranging in size from 0.01 µm to 0.4 µm, while fungal spores are at the upper end of the range and can be larger than 20 µm. Bacteria range in size from 0.5 to 10 µm. Deadly pathogens like the bacterial Bacillus Anthracis spore powder used in the anthrax cases generally range from 1 to 6 µm. The relevant size measurement used in aerosol science is the aerodynamic diameter. This diameter is usually different from the actual particle size of microorganisms, and accounts for the non-spherical nature of the cells. This parameter is more useful for predicting aerodynamic behavior of a particle in air.

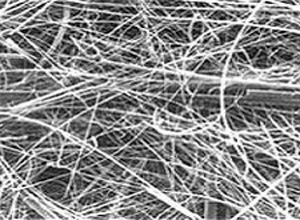

Figure 1. HEPA filters are made from numerous synthetic fibers that are laid down in overlapping, random order.

Figure 2. HEPA filter fibers

The idea is not to restrict particle passage by capturing target pathogens between closely spaced threads, but to divert and convolute the passageways of airflow. As airflow twists and turns through the overlapping threads, heavier objects—such as bacteria, spores, virus particles, or toxins that are in particle form—will not be able to keep up due to their greater inertia in relation to air molecules. The slower particles will hit the threads and be stopped. Since the synthetic fibers are designed to be "sticky," these particles lodge into the filter elements and are captured. Because HEPA filters capture the microorganisms, health effects caused by live microorganisms (infectious disease), and those effects that can be caused by live or dead microorganisms, such as allergies, are both mitigated. HEPA filters are widely used in clean rooms and in portable room air purification units.

There are a number of limitations with HEPA filters that make it essential to combine filtration with other technologies in order to ensure effectiveness in a ventilation system. First, HEPA filters will work well (99.97% efficiency) for particles down to about 0.3 µm. Because the aerodynamic diameter of a virus ranges down to 0.01 µm, many viral agents will not be removed at a high efficiency. Secondly, even a tiny puncture in a filter, or a manufacturer's bad quality batch, can significantly reduce performance and endanger an entire building's population. Thirdly, installation quality is of critical importance, and leaks or poorly fitting frames can destroy the integrity of the filtration system. Finally, the installation of HEPA filtration in the plenums of major building HVAC systems has a significant impact both on airflow throughput and energy consumption. Additional costs to consider are the replacement and disposal of the filters. Handling is especially important if there are suspected pathogens in the fibers of the filters.

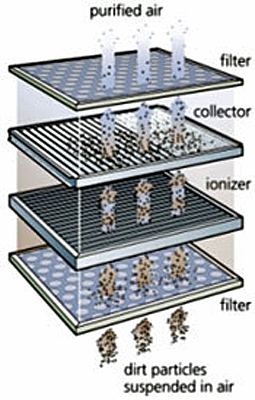

Another well-known filtration technology is based on electrostatic precipitation. Electrostatic filters precipitate particles out of the air by passing contaminated air through a highly charged field (ionizer). Particles are charged and then captured on electrode plates with the opposite charge (collector). Three key factors make this a good home technology but less effective in large buildings: 1) electrostatic systems need to slow the air flow substantially to allow all particles to be charged—an issue which is possible with exhaust pollutants but may be impossible to achieve in big HVAC systems; 2) these filters require large amounts of energy per volume of air decontaminated; and 3) a by-product of the process, ozone is itself a dangerous pollutant with significant risks. Ozone will be produced in large quantities in any industrial electrostatic application. Recently, bacteria and fungi removal has been tested in smaller ozone free electrostatic precipitators. For the precipitators tested, the maximum removal efficiency was 81%. Smaller size microorganisms were more difficult to remove, making the use of this technology more tentative for virus removal.

Figure 3. An electrostatic precipitator contains two components, an ionizer and a collector. The ionizer gives a positive charge to dirt particles in the incoming airstream, which then adhere to a negatively charged collector. The resultant outgoing air is cleaned and purified.

Source: Precision Graphics

B. Ultraviolet Irradiation

The ability of UV radiation—a portion of the electromagnetic spectrum from 100nm-400nm—to inactivate biological pathogens has long been known. UV radiation works by damaging the DNA and other cell components of a microorganism to the point that the cell cannot replicate. Cells that have been exposed to UV may still be viable, they just cannot replicate, and therefore they are not infectious. In 1903, one of the first Nobel Prizes in Medicine was awarded to a doctor from Denmark, Niels Ryberg Finsen, for recognizing and using the UV bactericidal effect of the sun in treating infectious skin disease. In the 1930s, Westinghouse developed UV bulbs, and since then a great deal of experimental work has been done to prove their germicidal efficacy. Ultra Violet Germicidal Irradiation or UVGI generally refers to UV wavelength of 254.7 nm. The wavelength is near optimal for damaging nucleic acid (DNA, RNA). UV irradiation by itself does not clean air. The microorganisms are still there, and in the case of some microorganisms, may still contain the ability to cause noninfectious (e.g. allergenic) disease. While there is potential for UV to destroy allergenic sites on the surface of a bioaerosol, this ability has not been documented or quantified.

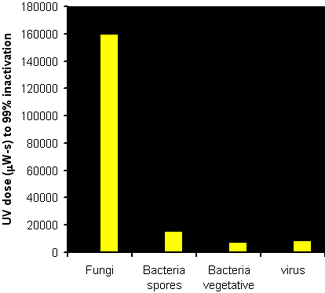

Figure. 4. UV germicidal dose required to inactivate 99% of microorganisms at 50% relative humidity in air. Dose value is for known UV-resistant species of each organism type. Aspergillis versicolor1 is used for fungi, B. subtilis spores2 for bacterial spores, B. subtilis3 for vegetative bacteria, and Adenovirus4, 5 for viruses.

UV irradiation is commonly used in the disinfection of drinking water. Although to a lesser extent, UV has also been used in the disinfection of air, mostly in health care settings. Anecdotal health information as well as laboratory research suggests it is an effective technology for inactivating airborne viruses, bacteria and their spores. However, there is a significant difference between addressing disease-causing organisms in a laboratory setting, and ensuring that deadly biological warfare pathogens are completely removed from an airstream. Installation, construction, and design of UV systems must be of paramount importance, and a focus of air decontamination must now include securing air streams in ducts and HVAC systems from outside infiltration. Since the threat of this kind of terrorism has only recently been realized, independent scientific investigators have begun to do fundamental research into the biological decontamination of airstreams to update this science. In November 2002, a major research study funded in part by the U.S. Department of Energy titled "Defining the Effectiveness of UV Lamps Installed in Circulating Air Ductwork" attempted to determine the effectiveness of UV germicidal radiation in inactivating bacteria and spores in a "typical" HVAC duct environment. The results are encouraging. The inactivation effectiveness can be very high (greater than 90%) for bacteria, although efficacy is less so for more resistant bacterial and fungal spores. Viruses were not tested in the study but research in the author's laboratory indicates that a highly UV-resistant virus (bacteriophage MS2) is less resistant to UV radiation (in air) than bacterial Bacillus Subtilis spores (regarded as the most resistant bacteria to UV radiation). Inactivation rates used for the design of UVGI systems should be determined from experiments where the microorganism has been aerosolized. Rates derived from agents suspended in water or irradiated on agar plates generally underestimate the airborne inactivation rate. In many cases, this may provide a desirable factor of safety. In other cases, it may lead to the expensive over-engineering of a system or unwarranted increases in operational costs. Laboratory research has also determined that air temperature, relative humidity, flow rate, lamp design, and ballast engineering have significant impacts on the effectiveness of these systems. Furthermore, the location of the decontamination UV array is of crucial importance because of the potential for air eddies and corners of ducting to allow some of the flow to pass through untreated. HVAC systems designers and control contractors will have to factor these components into their plans, and base decontamination systems designs on tested parameters in order to ensure maximum effectiveness. Because of the constant airflow in modern ventilation systems, making this work in an HVAC system requires coordination between dampers (in order to slow the passage of the air enough to allow all particles to receive a sanitizing ray of UV light) and the UV light itself. While this kind of attention to detail might not be necessary in installations primarily concerned with improving the day-to-day healthiness of air, in order to control the spread of a deadly bio-terrorist pathogen (such as anthrax or smallpox) the design of a UVGI system is of critical importance.

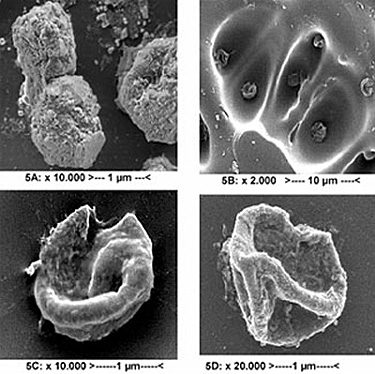

The effectiveness of UV light as a germicidal agent has resulted in two other techniques for decontamination. Pulsed UV (PUV) involves pulsing UV lamps at high power at regular intervals. This technology is being increasingly applied for air and surface sterilization and decontamination due to the powerful use of advanced UV light lamps and efficient energy consumption. This is a procedure, which appears to have certain advantages of very high inactivation rates for most known microorganisms. PUV is also effective on very hazardous and "hard-to-break" toxic organic compounds and odors from water, air, or surfaces without producing ozone at a very high speed. These systems use mercury-free flash lamps that emit pulses at such high energy that the cells are actually physically destroyed. To have this mechanism work, the rate of the energy deposition into a microorganism (the fluency rate) must be higher than its rate of cooling to a surrounding media. In this case, a microorganism undergoes momentous overheating and disintegration. It is shown that only the Pulsed UV light of a broad spectra can effectively do this work while Pulsed White Light (PWL) plays no role. Because of this disintegration action on a microorganism, this pulsed UV sterilization method is named as the Pulsed UV Disintegration (PUVD). Advantages and limitations of this method are compared with those of other established sterilization methods. Pulsed UV can sterilize and disinfect by producing greater than 6 log kills of microorganisms spores and organic compounds.

Figure 5A. Untreated spores of A. Niger. Figure 5B. Spores of Aspergillus Niger treated to two pulses at 33 kw/cm². Note craters around spores formed by sinking of heated spores into the PET substrate.1 Figure 5C. A single spore treated to two pulses of 33 kW/cm². Note how the spore top was ruptured by an escape of the overheated content of the spore. Note also the crater around the spore. Figure 5D. A single spore treated to 5 pulses of 5 kw/cm² each, open lamp.2

Photos courtesy of Dr. Alex Wekhof

Another technique that has been suggested in building design is to use the natural UV component of sunlight to treat air. This process is called passive solar decontamination. In this scenario, buildings would be constructed with UV transparent walled air passages that surround the outside of the structure. Filtered air would rise through many stories and receive lethal UV (solar) doses of natural sunlight as it passed up the columns. After being decontaminated by sunlight, it would enter the building's HVAC system and be cooled (or heated) and distributed throughout the building. This is an intriguing possibility, however, because ozone in the earth's atmosphere filters out the most effective germicidal portion of solar radiation, inactivation rates from sunlight are quite slow (even in Arizona). In the case of spores, sunlight is not an effective disinfectant. Indeed, spores have evolved to withstand harsh environments and contain tremendous DNA repair capabilities.

The EPA has issued several warnings concerning UVGI companies that make unsubstantiated claims as to the effectiveness of their technology. For example, be careful of reports by sterilization and decontamination companies making claims such as "the simultaneous emission of ultrasound or ultrasonic waves and ultraviolet light complement each other and can effectively sterilize either organic or inorganic items in a non-liquid environment." No white paper or peer reviews have ever been published confirming these claims. The public is advised to use proven methods of controlling indoor air pollution.

C. New/Experimental Technologies

A number of other technologies, new or at a more experimental stage, may be useful for decontaminating air in buildings.

One process is called ozonation. Ozone is piped into an air chamber where it is thoroughly mixed with air. Ozone reacts with organic particles and pathogens, oxidizing microorganisms and other chemical toxins. While there may be applications in decontaminating a room, this technology is not applicable to flow in a ventilation system. Additionally, ozone generation is energy intensive. Removing the ozone from the airstream is complex, and involves the use of synthetic catalytic compounds that lose effectiveness over time as they are saturated with the gas molecules. While there have been successful water sterilization systems developed using ozone, the process has yet to be tested on airborne pathogens. The EPA lists ozone as a priority air pollutant and warns that levels of ozone required to inactivate airborne microorganisms would be in excess of the current ozone standards. The EPA publication, Ozone Generators that are Sold as Air Cleaners: An Assessment of Effectiveness and Health Consequences, states: "Available scientific evidence shows that at concentrations that do not exceed public health standards, ozone has little potential to remove indoor air contaminants. If used at concentrations that do not exceed public health standards, ozone applied to indoor air does not effectively remove viruses, bacteria, mold, or other biological pollutants."

Another decontamination technique related to filtration is air purging. This is the process of flooding a building with clean outside air in order to expunge and dilute contaminated air. This can be an effective procedure in the aftermath of a biological attack, but requires vacating the building; opening all windows, doors, and access ways; and then forcing massive quantities of outside air into the facility. This can be an effective post-incident response, but does nothing to secure a facility during an attack, or on a day-to-day basis.

Photocatalytic oxidation is another sterilization technology and is based on the production of several highly reactive short-lived chemical compounds—oxygen-based radicals and ions—that are effective in microorganism disinfection and neutralizing volatile organic compounds (VOCs) or other chemical aerosols. These reactive compounds are produced by applying short wavelength light (sunlight works well) to titanium dioxide (TiO2) coatings. Oxidant coatings can be put in paints on walls or used to coat HEPA filters. The effectiveness of photocatalytic oxidation has been well documented in publish research. Usually the microorganism is completely destroyed. While power consumption is low, high enough efficiency for fail-safe bio-terror applications has not been demonstrated. It is possible that photocatalytic oxidation may have a place in decontamination systems of the future.

Another chemical filtration technology that has been proposed is the use of activated carbon (AC) filters. Carbon adsorption operates by virtue of the large surface area of activated carbon and the tendency for these surfaces to trap and hold onto large organic molecules. A grain of activated carbon has a tremendous amount of surface area. Activated charcoal is charcoal that has been treated with oxygen to open up millions of tiny pores between the carbon atoms. Advances in manufacturing techniques have resulted in highly porous charcoals that have surface areas of 300-2,000 square meters per gram. Activated charcoal is good at trapping other carbon-based impurities ("organic" chemicals), as well as things like chlorine. Many other chemicals are not attracted to carbon at all—sodium, nitrates, etc.—so they pass right through. This means that an activated charcoal filter will remove certain impurities while ignoring others. It also means that, once all of the bonding sites are filled, an activated charcoal filter stops working. At that point you must replace the filter. AC filters can be a breeding ground for microorganisms. While carbon adsorption is a common technology in VOC removal from airstreams its effectiveness in removing biological pathogens in a ventilation application is not known.

Application

It is hard to imagine a location where healthier, cleaner, safer air would not be desirable. While biological terrorism may be an isolated occurrence, protecting airflows in buildings, while greatly improving the health of the occupants from things as simple as the rhinoviruses that cause colds, makes a great deal of sense. The return on investment from upgrading air handling systems far outweighs the costs. At a minimum, modified or newly constructed buildings should be equipped with some type of efficient, low pressure drop filtration system. Secure rooms, safe havens, and highly vulnerable areas like mail rooms and lobbies, should be fitted with second and third stage decontamination systems. At present it appears that UVGI technology when used in conjunction with filtration is an effective option for building managers to consider for cost effectively offering a level of protection from airborne microorganisms within the building envelope and interior systems. When proper measures are chosen for buildings, and integrated into the design process, the result/performance of any upgrade is dependent on the installation, operation, and continuing maintenance. The DoD has established "DoD Minimum Anti-Terrorism Standards for Buildings" that require the limitation of airborne contamination within its buildings. Air decontamination creates a safe and healthy environment for its occupants and has real economic impact because of its dual use from a security and environmental perspective. When designing buildings, value engineering many times compromises health and security risks. Current opinion is that guidelines and standards will be published that will include air decontamination system upgrades or modifications rather than new requirements to the building codes.

The Worldwide web is an important source of further information on this topic. Web information provided by government agencies and professional societies is the most reliable and is usually based on peer reviewed research. Technical peer reviewed research journals are also reliable sources, and focus more on the fundamental science behind each technology. Use caution with data presented on websites that are not substantiated by peer review literature or results from well-documented experiments.

Relevant Codes and Standards

ASHRAE

- ASHRAE Guideline 1.1 HVAC&R Technical Requirements for The Commissioning Process

- Standard 52.2 Method of Testing General Ventilation Air Cleaning Devices for Removal Efficiency by Particle Size

- Standard 62.1 Ventilation for Acceptable Indoor Air Quality

- Standard 90.1 Energy Standard for Buildings Except Low-Rise Residential Buildings

Department of Defense

- UFC 4-010-01 DoD Minimum Anti-Terrorism Standards for Buildings

- FM 3-19.30 Physical Security—Sets forth guidance for all personnel responsible for physical security.

- NAVFAC MIL-HDBK-1013 series

- Tri-Services Unified Facilities Guide Specifications (UFGS)—UFGS, organized by MasterFormat™ divisions, are for use in specifying construction for the military services. Several UFGS exist for sustainability and security/safety-related topics.

Department of Homeland Security

- BIPS 06 / FEMA 426 Reference Manual to Mitigate Potential Terrorist Attacks Against Buildings

- BIPS 07 / FEMA 428 Primer to Design Safe School Projects in Case of Terrorist Attacks and School Shootings

Federal Emergency Management Agency (FEMA)

- FEMA 386-7 Integrating Manmade Hazards into Mitigation Planning

- FEMA 427 Primer for Design of Commercial Buildings to Mitigate Terrorist Attacks

- FEMA 429 Insurance, Finance, and Regulation Primer for Terrorism Risk Management in Buildings

- FEMA 452 Risk Assessment: A How-To Guide to Mitigate Potential Terrorist Attacks Against Buildings

- FEMA 453 Design Guidance for Shelters and Safe Rooms

GSA

- PBS-P100 Facilities Standards for the Public Buildings Service, GSA Mechanical and Air Handling Requirements, Chapter 5

Other Standards

- American Conference of Governmental Industrial Hygienists (ACGIH)—Provides threshold limit values for chemical substances and physical agents and biological exposure indices.

- Occupational Safety and Health Administration (OSHA)

- Code of Federal Regulations, 29 C.F.R. § 1910.1000 "Air Contaminants"—Examines air contaminants, permissible exposure limits.

Additional Resources

Organizations

- American Society of Heating Refrigerating and Air-Conditioning Engineers (ASHRAE)

- ASIS International—Locates security specialists and provides the Crisis Response Resources link to find information related to terrorism and building security

- Building Owners and Managers Association (BOMA)—Information on emergency planning and security assessments

- Centers for Disease Control and Prevention (CDC)—Health guidance for CBR agents

- Central Intelligence Agency (CIA)

- International Facility Management Association (IFMA)—Information on security-related training courses

- Lawrence Berkeley National Laboratory—Website with advice for safeguarding buildings against chemical or biological attack

- National Institute for Occupational Safety and Health (NIOSH)—Health and safety guidance, publications, and training information

- U.S. Environmental Protection Agency (EPA)

- Homeland Security and the Indoor Environment—Provides many links and references to security and air issues

- U.S. General Services Administration (GSA)

Publications

- Anthrax-Contaminated Facilities: Preparations and a Standard for Remediation by the Congressional Research Service. 2005.

- ASHRAE Handbook and Product Directory by American Society of Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE). 1979. Air cleaners. Equipment.

- Building Air Quality: A Guide for Building Owners and Facility Managers by EPA.—Provides procedures and checklists for developing a building profile and performing preventive maintenance in commercial buildings

- PBS-P100 Facilities Standards for the Public Buildings Service by GSA.—Establishes design standards and criteria for new buildings, major and minor alterations, and work in historic structures for the Public Buildings Service. Also provides information on conducting building security assessments.

- NIOSH 2002-139 Guidance for Protecting Building Environments from Airborne Chemical, Biological, or Radiological Attacks.

- Risk Management Guidance for Health and Safety under Extraordinary Incidents by ASHRAE. 2003. This report provides guidance for new and existing buildings regarding the protection of air, water and food systems.

Figure 4 Footnotes

1 [Douglas VanOsdell and Karin Foarde (2002). Defining the effectiveness of UV lamps installed in the circulation air ductwork. Air Conditioning and Refrigeration Technology Institute. Report # ARTI-21CR/610-40030-01.]

2 [Peccia, J. and M. Hernandez. (2001). Photoreactivation of airborne Mycobacterium Parafortuitum. Applied and Environmental Microbiology. 67: 4225-4232.]

3 [Peccia, J., H. Werth, Miller, S. L and M. Hernandez. (2001). Effects of relative humidity on the ultraviolet inactivation of airborne bacteria. Journal of Aerosol Science and Technology, 35: 728-740.]

4 [Jensen, M.M. (1964). Inactivation of airborne viruses by ultraviolet irradiation. Applied Microbiology, 12: 418-421.]

5 [Kowalsiki, W.J., Bahnfleth, WP. (2001). UVGI design basics for air and surface disinfection. IUVA News, 3:4-7.]

Figures 5 and 6 Footnotes

1 [Wekhof, A., J. Trompeter, O. Franken, (2001). "Pulsed UVB Disintegration (PUVBD): A New Sterilization Mechanism for Broad Medical-Hospital and Packaging Applications." Proceedings of the First International Congress on Ultraviolet Technologies, June 15-17, 2001. Washington DC, USA.]

2 [SteriBeam Systems GmbH, Phone: (916) 984-6551.]