by Joseph C. Dean, P.E., Robert J. Evans, Jr., P.E. (AFCEC), Lean-Miguel San Pedro (NAVFAC). Rebekah Wilson (CERL), and Steve Geusic, P.E. for the Director, Corrosion Policy & Oversight (DCPO), (DASD) [Materiel Readiness]

Updated: 11-09-2021

Introduction

Within This Page

The Corrosion Prevention and Control (CPC) Checklists Tool contains three editable checklists for use by planners, design engineers and architects, and sustainment professionals in the planning, designing, and constructing of facilities, with CPC requirements included. This includes creating:

- CPC project plans

- Coordinating CPC actions with the RFP

- Developing a design that includes CPC

- Establishing Quality Assurance (QA), Contractor Quality Control (CQC), Commissioning (Cx) Programs for CPC requirements in the Request for Proposal (RFP) and Design

- CPC Design Review (both for inhouse and contractor) Plans

- CPC sustainment programs

These Checklists are meant to provide a guide on how to evaluate a project for appropriate CPC and should be tailored to meet the specific project scope and circumstances. These lists should be coordinated with contract requirements to ensure that they are consistent and do not overreach. Use of these checklists can help validate each process step to ensure inclusion of appropriate CPC requirements. If the Checklists are to be used for inhouse projects where government employees are actually performing the work, they can be used to assist in project planning, work execution and project closeout.

The Checklists can be an essential part of meeting both CPC project planning and contract expectations. Ensuring that the Checklist is described in the Contract RFP will set expectations for the completed project.

The CPC Checklists can be found in the WBDG Tools section (Checklists 1—3 including checklist questions, organization, and references) are intended to serve as an assist for facilities professionals (government and contractor) in addressing CPC contract requirements. It is not intended to be complete or apply in every situation (contract, SRM action, RFP). The user must apply good engineering judgement and practice in developing an appropriate checklist that applies to the specific contract and project (procurement, in-house job). Research into every applicable reference is necessary to ensure compliance with the contract and project. The UFC 1-200-01 DoD Building Code lists Environmental Severity Zones for each DoD location. These Zone designations must be adhered to in developing a design and in selecting appropriate CPC materials and building element corrosion mitigating requirements. Addressing micro-environments will apply in specific areas (swimming pool enclosures, chemical storage, etc.).

Description

The CPC Checklists were developed in response to questions from facilities professionals' request for assistance in evaluating corrosion programs, either at the contract, project, or in-house evaluation levels. The Checklists incorporate CPC into facilities programs. They attempt to serve as an assist, or reminder, for the facilities professional emphasizing timing, expectations, qualifications, and specific technical requirements.

The phrases "you do not know what you do not know," and, "if you have not seen it before, you will not know what it is" applies here. Increasing knowledge and awareness with the assistance of these Checklists will increase the facilities professional's chances of addressing CPC at the level necessary to achieve design and life cycle expectations. By leveraging the Checklists, many years of expertise and insights are instantly at the fingertips of the Facilities Professional. Knowing when to engage, with the right question (and knowledge) will improve the project, SRM/Repair Program, and the life cycle performance. For example, selecting the appropriate coating based upon ESC Zone (including micro-environments) or a cathodic protection system during the planning and early stages of the design will facilitate getting those requirements into the contract and the constructed facility.

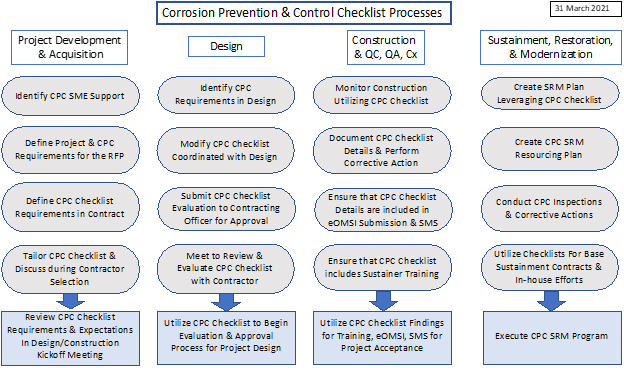

Figure 1 illustrates the high-level processes delineated in the Checklists within the four process areas of Project Development and Acquisition; Design; Construction including Quality Control, Quality Assurance, and Commissioning; and Sustainment (including Repair), Restoration, and Modernization.

Figure 1 Corrosion Prevention & Control Checklist Processes

Source: J.C. Dean, P.E.

Each Checklist in the WBDG Tools section is tailorable to the specific program or project requirements. The following summaries apply:

-

Checklist 1 Corrosion Prevention and Control (CPC) Checklist Organized by Facility Life Cycle Steps is intended to be focused on a higher level for project and program planning. It does show the full life cycle and is intended to assist with "beginning with the end in mind."

-

Checklist 2 Corrosion Prevention and Control (CPC) Checklist Organized by Facility Program Management Categories focuses on the project management details to include requirements for management, technical qualifications, training, safety, quality control, and Sustainment Management System (SMS) data management. It addresses the non-technical aspects of the project. By reviewing and selecting the appropriate requirement entry into the RFP, the government will be assured of seeing these actions become a realty during the project and, obviously, sets contractor expectations.

-

Checklist 3 Corrosion Prevention and Control (CPC) Design and Construction Checklist Organized by Facility System is the most extensive and requires a great deal of planning and understanding of the ESC Zone, the applicable criteria, and design expectations. These requirements must be delineated in the contract such that they will be realized in the completed project. It should be clear that the Checklists are intended to stimulate ideas as to the extent of CPC mitigation and prevention required in the completed contract. There are a number of entries referring to readiness and availability. The facilities professional on a military installation should always have that focus in mind. The obvious example is a pier, corrosion control facility, or runway. If those facilities are dysfunctional then a ship cannot tie up and receive hotel services, essential aircraft maintenance cannot be performed, or aircraft cannot land. Perhaps not as obvious is the HVAC system in a barracks. If it is not working and the squadron members cannot sleep, their ability to provide aircraft maintenance in a safe manner will be at risk.

It is essential that the facilities professional include the CPC Subject Matter Experts (SME) in project planning. It is also critical that the design process for each location include the SME in project development and quality assurance actions. The designer of record and the SME both have obligations to collaborate to ensure that the project meets expectations and life cycle requirements. Making certain that the completed project is maintainable should also be an objective.

Lessons Learned from the field include the following topics which should be addressed when editing the applicable Checklist:

-

Prior to construction, identify the CPC survey schedule no less frequently than mandated by each specific Service and develop the survey template using minimum requirements as a guide. This time period should be audited as necessary dependent on corrosion impact post construction.

-

During the planning period identify the funding levels required after construction to ensure support for sustainment.

-

Reviewing the UFC 1-200-01 DoD Building Code and ensuring specific Military Service and Component CPC requirement/guidance. This includes the AR 420-1 Facilities Engineering: Army Facilities Management, and AFI 32-1054 Civil Engineer: Corrosion Control

-

Identify and seek the assistance of the Corrosion SME who will be the POC for the planning, RFP development and construction phases.

-

Establish who will be responsible for ensuring that CPC requirements have been met on site and who is the Corrosion SME POC in their service (Army, Navy, Air Force) that will serve as backup support.

-

Ensure that the appropriate Corrosion SME reviews project specifications for CPC compliance. It should be noted that SMEs catch a lot of issues during reviews in areas such as cathodic protection and paint/coatings sections of a job specification, identifying incorrect coatings systems, lack of QA/QC/Inspections, and design issues with CP systems.

-

For instances where the Corrosion SME review does not occur there is a high probability for field failures where dissimilar metals, for example, are specified even though UFC 1-200-01 covers this. Due to lack of understanding of CPC Science, dissimilar metals are selected and placed into service with the associated accelerated corrosive behavior.

-

Ensuring that building components that have been identified as high corrosion risks are flagged in the Sustainment Management System (SMS) along with other condition reports ensuring that these risk areas are monitored at the appropriate levels for follow-on corrosion maintenance actions.

Summary

Several facilities CPC experts contributed to the development of the three CPC Checklists. The Checklists have been created to provide an easily accessible, editable document to help facilities professionals develop and put in place the most appropriate design solutions consistent with life cycle requirements, creating a more sustainable and durable project. Facilities professionals, including program managers and planners, may not be aware of all the CPC mitigation technology available to them. The Checklists are a starting point and will assist in asking and addressing their CPC questions. By leveraging the Checklists, CPC life cycle requirements and mitigation techniques will be improved.

Additional Resources

WBDG

- Unified Facilities Criteria Program

- UFC 1-200-01 DoD Building Code

- Corrosion Prevention and Control Source

- Tools

Military Services

- AR 420-1 Army Facilities Management

- AFI 32-1054 Corrosion Control

- Marianas Navy and Marine Corps Design and Construction Standards (MDACS), September 2017

Checklist Examples

(Note that some of these are not CPC related. They provide a format for creating a focused checklist and insights into the associated thought process.)

- GSA Commissioning Guide

- Design Review Checklists

- CPC Checklist Tool

- AIA Alternate Care Sites Preparedness

- SSPC/NACE JOINT STANDARD PRACTICE SSPC CPC-1/NACE SP21412-2020 Corrosion Prevention and Control Planning

- Corrosion Prevention and Control Checklist