Introduction

Within This Page

In many construction projects, building materials are evaluated and selected based on performance, aesthetics, and cost. With "green" or environmentally preferable products, these selection parameters are expanded to include both health and environmental impacts. Environmentally-preferable products (EPPs), as defined by the federal government in Executive Order 13101, are those that have "a lesser or reduced effect on human health and the environment when compared to competing products that serve the same purpose." As currently addressed by designers and manufacturers alike, green products are those with reduced life-cycle impacts (as defined through life-cycle analysis) and which reduce or eliminate harmful chemical content.

The growing popularity of green buildings and green building rating systems such as LEED®, Green Globes, the WELL Building Standard, the Living Building Challenge, and others, has expanded both the demand for and availability of, green products. Just as important is the increased availability of detailed environmental and health-related materials information—often referred to as product transparency data. While these developments are providing greater opportunities to improve the "green" characteristics of many building products, assessing the health and environmental impacts of materials is a complex process, involving new skill sets and vetting processes. Fortunately, an expanding number of resources and tools are available to streamline the evaluation process and assist project teams in making appropriate, informed selections.

Brock Environmental Center—Virginia Beach, Virginia. In this LEED Platinum building, natural materials from the U.S. Southeast (wood, uncoated metals) reinforce a sense-of-place, while reducing chemical constituents. Material ingredients were documented to ensure no LBC red-list chemicals were included. Products were locally sourced (500 km radius for dense materials) and the majority of materials, like wood siding, zinc shingles, drywall, lighting, mechanical systems, appliances, and finishes are US-made. Salvaged building products were used extensively and celebrated within the design. All virgin (non-recovered) wood was FSC-certified.

Photo Credit: Prakash Patel Photography, courtesy of SmithGroupJJR

Description

While the most comprehensive method to assess green materials is through the use of product transparency data (reviewed further in the sections below), the most common indicators of green products are one or more of the following health and/or environmental attributes:

- They promote good indoor air quality (typically through reduced emissions of VOCs and/or formaldehyde);

- They are durable and have low maintenance requirements;

- They incorporate recycled content (post-consumer and/or post-industrial);

- They have been salvaged from existing or demolished buildings for reuse;

- They are made using natural and/or renewable resources;

- They have low "embodied energy" (the energy required to produce and transport materials) and corresponding low embodied carbon emissions;

- They do not contain CFCs, HCFCs, HFCs or similar chemicals that result in ozone depletion or high global warming impacts;

- They do not contain highly toxic compounds, and their production does not result in highly toxic by-products;

- They are obtained from local resources and manufacturers;

- For wood or bio-based products, they employ "Sustainable Harvesting" practices;

- They can be easily reused (either whole or through disassembly);

- They can be readily recycled (preferably in a closed-loop "circular" recycling system);

- They are biodegradable at the end of their service life.

West façade of the University of Washington Life Sciences Research Center. The project received an AIA COTE Top Ten Award and a UL listing. The design emphasizes resourceful use of materials that enhance the broader campus ecology. The design team implemented solutions to improve indoor air quality during and after construction, ensuring that adhesives, sealants, paints, flooring, and composite wood had low or no VOCs. Ten percent of the building materials were recycled and 10% were locally sourced.

Photo Credit: Kevin Scott

The characteristics of green products vary significantly depending on the material type. With concrete, for instance, the most impactful issues involve the high embodied carbon inherent in the production of Portland cement; a "greener" version of concrete often includes the use of ground granulated blast furnace slag (a pre-consumer recycled material), recycled glass pozzolans, or other supplementary cementitious materials that utilize recycled resources and reduce the amount of Portland cement in the mix. The green attributes of an interior paint, by contrast, might focus on low VOC content and the reduction of harmful chemical content. It is also not uncommon for specific materials to have positive attributes under some sustainability or wellness categories, but negative attributes in others.

Because of these degrees of variability and complexity, the evaluation of green products requires a working knowledge of:

- Relevant health and environmental life-cycle issues associated with different material types;

- Government, industry, and third-party standards for green products, where they exist; and

- Available green products in the marketplace, including their specific green attributes, performance profiles, appearance, and costs.

To assist those just beginning to undertake this process, the sections that follow define key terms, suggest methods for assessing materials for their environmental and heath characteristics, and introduce key available resources.

A. Definitions

As suggested from the above description, a wide range of terminology has developed in the field of green products. The following definitions represent a sampling of terms that are integral to the discussion on environmentally preferable materials.

Certified or Sustainably Harvested Wood—Wood products obtained from "well-managed forests," usually certified through third-party organizations. While there is currently no industry consensus on what constitutes sustainable forest management, several organizations have established criteria, most notably the Forest Stewardship Council (FSC). In general, well-managed forests conserve biological diversity, water resources, soils, and the overall ecosystem of the forest.

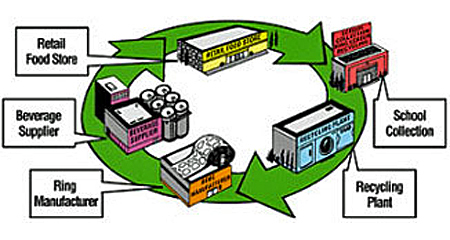

Circular Economy—As defined in the US EPA's National Recycling Strategy, a circular economy is an industrial system that is restorative or regenerative by design. It is a change to the linear model from which resources are mined, made into products, and then thrown away. A circular economy reduces materials use, redesigns materials and products to be less resource intensive, and recaptures "waste" as resources to manufacture new materials and products. Materials in a circular economy system are similar to those in a "closed loop" recycling process (a recycling process in which a manufactured product is recycled back into the same or similar product without significant deterioration of the quality of the product). However, a circular economy approach emphasizes whole systems thinking to create efficiencies and benefits throughout the entire material life cycle.

Embodied Energy and Embodied Carbon—The total energy required to produce a finished product, including the energy used to grow, extract, manufacture, and transport it to the point of use. Embodied carbon similarly refers to the carbon emissions produced through a product's life cycle, expressed as CO2e. This includes the emissions that occur during the manufacture, transport, construction process, and end-of-life aspects of a product and its components.

Emissions Testing—A process in which a product sample is subjected to a standardized laboratory test procedure that measures the emissions of targeted chemicals (typically VOCs—see definition below) from the product over a specified period of time. Green building rating systems such as LEED and WELL refer to specific industry test procedures, most commonly the California Department of Public Health (CDPH) Standard Method . The product emission test results are typically compared to maximum VOC threshold concentrations (defined in the CDPH Standard Method) to determine if the product "passes" the emissions test. Most manufacturers who perform emissions testing on their products will provide certificates or reports issued by the testing agency that verify the testing results.

Environmental Product Declaration (EPD)—A transparent, objective report that communicates what a product is made of and how it impacts the environment across its entire life cycle. EPDs satisfy all of the requirements of Product Category Rules (PCR) and follow international standards, including ISO 14044, ISO 14025, and ISO 21930.

Health Product Declaration (HPD)—A document that provides a detailed disclosure of the potential chemicals of concern in products by comparing product ingredients to a set of priority "hazard" lists based on the GreenScreen for Safer Chemicals and additional lists from other government agencies. An HPD is intended as a standardized format for product disclosure and does not necessarily mean a product is "healthy." HPDs can be used, however, to compare the content of hazardous chemicals that may be included in various products. For more information see the Health Product Declaration Collaborative.

Indoor Air Quality (IAQ)—According to the U.S. EPA and the National Institute for Occupational Safety and Health, the definition of good indoor air quality includes: (1) the introduction and distribution of adequate ventilation air; (2) the control of airborne contaminants; and (3) the maintenance of acceptable temperature and relative humidity. IAQ is one aspect of Indoor Environmental Quality (IEQ), which includes other important issues such as lighting quality, daylight and view access, thermal comfort, and acoustical quality.

Acceptable indoor air quality is defined by ASHRAE Standard 62.1-2019 as "air in which there are no known contaminants at harmful concentrations as determined by cognizant authorities and with which a substantial majority (80 percent or more) of the people exposed do not express dissatisfaction."

Life Cycle Analysis (LCA)—A methodology for assessing the environmental impacts associated with all the stages of the life cycle of a commercial product, process, or service. According to ISO 14040, LCA is defined as the following: LCA studies the environmental aspects and potential impacts throughout a product's life cycle (i.e. cradle-to-grave) from raw materials acquisition through production, use and disposal. The general categories of environmental impacts needing consideration include resource use, human health, and ecological consequences.

Pre-Consumer Recycled Material—A material that is removed from production processes (including scrap, breakage, or by-products) and reused in an alternative process before consumer distribution. Example: mineral (slag) wool, a by-product of the steel blast furnace process, used for mineral fiber acoustical ceiling panels.

Sustainably harvested wood flooring at GAP Headquarters

Courtesy of EcoTimber

Post-Consumer Recycled Material—A reclaimed waste product that has already served a purpose to a consumer, and has been diverted or separated from waste management collection systems for recycling. Example: used newspaper that is made into cellulose building insulation. Refer to definitions—ISO 14021 - Environmental labels and declarations - Self-declared environmental claims (Type II environmental labeling).

Recycled cotton/polyester insulation and cellulose insulation are viable alternatives to hazardous fiberglass insulation.

Courtesy of Green Building Resource Guide

Latex paint can be sent to a paint recycler and reprocessed into quality paints.

Courtesy of Amazon Paint

Safety Data Sheet (SDS)—OSHA-required documents supplied by manufacturers of products containing hazardous chemicals. SDSs contain information regarding potentially significant levels of airborne contaminants, storage and handling precautions, health effects, odor description, volatility, expected products of combustion, reactivity, and procedures for spill cleanup.

Third-Party Certification—The certification of a specific product or process performed by an organization independent from those who produce the product or process. Certification is often used to substantiate the environmental attributes of specific products (such as the percentage of recycled content) or processes (such as a sustainable harvesting operation for forests).

Volatile Organic Compound (VOC)—Chemicals that contain carbon molecules and have high enough vapor pressure to vaporize from material surfaces into indoor air at normal room temperatures (a process known as off-gassing). While most VOCs are relatively inert at typical indoor concentrations, they can react with oxidants such as ozone and possibly nitrogen oxide and nitrogen dioxide to form reactive species and possibly strong irritants, including various acids and aldehydes. VOCs may cause eye and upper respiratory irritation, nasal congestion, headache, and dizziness. Examples of building materials that contain VOCs include, but are not limited to, solvents, paints, adhesives, carpeting, and particleboard.

Application

Making Selections

Given the wide range of issues involved in evaluating and identifying environmentally preferable materials, an initial question for many may be, "How do I start?" While there is not one definitive process for selecting green materials, practitioners will inevitably employ the following strategies to varying degrees:

-

Become familiar with the industry tools and resources. There is a large and growing number of available resources, many of which are essential to making informed material selections. The Tools and Resources section below is a listing and description of key information sources to begin this process.

-

Develop a systematic research and vetting process that begins at a manageable level and then grows the system further as expertise is developed. The following sections suggest approaches at both Beginner and Advanced Levels.

Beginner Level

- Define the scope:

-

As previously noted, there are many sustainability and health characteristics that apply to building materials, and the issues can vary significantly based on the material types. To make the process manageable, start by defining the highest priority material types you intend to address. An initial scope may include:

-

Commonly-used flooring, wall, and ceiling finishes. The initial focus for these products may be health and wellness considerations since building occupants are most directly exposed to these materials.

-

Major structural materials including concrete, steel, masonry, and wood. These high mass materials typically represent the highest embodied carbon elements in a project (wood being the exception), so the initial focus may be on characteristics that can reduce their carbon footprint, such as recycled content and local procurement. In structures that are predominantly wood, sustainable sourcing of the forest products will typically be the focus.

-

- BuildingGreen's "12 Product Rules" is also a useful guide for making material prioritization decisions. Ultimately, it is important to consider the aspects of the materials procurement process that are particularly important to you, your client, and the users of the project. Social equity, for instance, can be an important factor in evaluating the companies and products that come under consideration.

-

- Lean on the rating systems:

- The Green Building Rating systems were developed over many years and draw on the expertise of many building professionals. The criteria these systems have established for materials provide the most direct way for practitioners to "jump start" the process of using green products, regardless of whether an actual certification is being pursued. Once familiar with the rating system criteria, use the sources identified in the Tools and Resources section to identify actual products that meet the sustainability and/or wellness requirements.

- Become familiar with product transparency information sources:

- The disclosure of detailed product transparency data is increasingly becoming the norm for building product manufacturers. Practitioners need to become familiar with documents such as EPDs, HPDs, emissions test reports, and other resources as described in the Definitions and Tools and Resources sections of this resource page. As an initial step, request product transparency data for the prioritized products in your project, even if you are not ready to use the information for optimization purposes. Requesting the data signals the importance of having this information to the manufacturers and allows practitioners to start processing the information and identifying differences among products.

- Become familiar with green product listings and certifications:

- Many manufacturers provide product transparency and other sustainability/wellness information directly on their websites. However, it is generally more efficient to use the specialized green product websites such as Mindful Materials or UL Spot to find multiple products with comparable green building information. Becoming familiar with these resources, and the differences in the information they provide, can help streamline the process of finding appropriate products. Most of the certification websites, such as Cradle-to-Cradle or SCS, also provide listings of products that have achieved their certifications.

- Develop initial green product specifications:

- While product vetting is a key aspect of incorporating green materials into a project, it is important to also define green performance criteria in the project specifications. Many projects allow "or equal" substitutions to be made for products that are listed in the construction documents, so it is critical that contractors understand the green performance criteria that must be met, as well as the supporting documentation that must be provided. As a first step, focus on the prioritized material types identified at the beginning of the project. Look to the specification resources listed below as models for green specification language.

Advanced Level

In addition to expanding the scope of material types under review, advanced materials research involves the use of more sophisticated tools and optimization assessments. Considerations can include the following:

- Utilize "Red Lists" for product screening:

- As referenced in the Tools and Resources section, programs such as the Living Building Challenge, Cradle-to-Cradle, Declare, GreenScreen Certified, and Six Classes use the concept of chemical "red lists" to prioritize the harmful ingredients that should be excluded from products. While these programs each have an approach that differs somewhat from the others, the overall intent is consistent, and there is overlap among the programs. Advanced users can use product transparency data and certifications such as C2C, Declare, and GreenScreen Certified as a basis to vet products and create listings of reduced-toxicity options.

- Use product transparency data to make "deep dives" into key material types:

-

In the Beginner Level section, it was noted that product transparency data such as EPDs, HPDs, and emission tests should be requested for all key material types. Advanced users can begin using this data as a basis for comparing products and looking for optimization opportunities. As noted under the Red List section above, transparency documents such as HPDs can be used to vet products against established Red Lists of harmful chemicals. HPDs can also be very useful in identifying the most common compounds used in certain material types and the percentages of each compound in the product (e.g., the percentage of pvc or other polymers in a carpet backing, the percentage of recycled gypsum in wallboard, the type and quantity of surface coating treatments in a resilient flooring product). This level of information can provide meaningful insights when comparing similar product types.

EPDs focus on the life-cycle impacts of a product and are particularly useful in assessing the embodied carbon differences among similar products. EPD comparisons must be done carefully, however, to ensure that the scope and reporting methodologies (PCRs) are consistent among manufacturers and products. LEED offers a credit associated with embodied carbon optimization reports or action plans prepared by product manufacturers as supplementary documents to their EPDs—the intent is to have manufacturers provide validated research that identifies their optimized products.

- The tools described in the following section can further assist teams in the "deep dive" process.

-

-

Begin using tools such as EC3, Pharos, and others:

In addition to reviewing individual product transparency documents, the use of online tools and other specialized software can assist project teams in performing more advanced product vetting.

-

The Embodied Carbon in Construction Calculator (EC3), for example, allows users to make embodied carbon comparisons of many major material types. Based on the user's selection criteria for a material under consideration (e.g., gypsum wallboard), the EC3 tool uses an extensive database of verified EPDs to define a range of embodied carbon intensities per standardized unit (e.g., kgCO2e embodied per 1000 SF of wallboard). The range reflects the variations in the industry, and the tool further defines a baseline level of performance as well as a suggested "achievable" embodied carbon target. Users can also access EPDs for specific products directly through the EC3 tool and see where these products rate within the established embodied carbon range.

-

To understand whole building LCA impacts, use software tools such as Tally, One Click LCA, and ATHENA. These programs allow users to quantify the various materials used in a building and aggregate their combined impacts to establish a whole building profile. Users can adjust various design factors of the building and/or select alternative materials to see how these strategies impact the overall LCA numbers. Rating systems such as LEED and BREEAM offer credits for performing whole building LCA assessments.

-

For assessing chemical content in products, the online Pharos tool provides a number of useful features for practitioners and researchers alike. Practitioners are most likely to use the Pharos listing of "Common Products", which provides detailed breakdowns of the compounds/chemicals used in "generic" versions of commonly-used materials (e.g., mineral fiber acoustical ceiling panels). For each of the identified ingredients, Pharos provides a hazards rating based on the GreenScreen hazards identification system. These profiles can provide a useful baseline for practitioners when evaluating individual product HPDs. Pharos also informs the HomeFree website, which provides recommendations for lower-toxicity materials in a number of product categories.

-

-

Review emerging initiatives such as biomimicry and social equity:

While much of the information related to environmentally preferable materials focuses on eliminating or reducing negative impacts, there are other initiatives to consider that address positive measures in material design and production, as well as in the operating policies of the manufacturers.

-

Biomimicry refers to a process in which organisms and systems in the natural world are observed and "mimicked" as inspiration for human engineering. The idea is to adopt solutions that have been proven based on the evolutionary processes in nature. While biomimicry concepts can be applied to many fields (energy, agriculture, fashion, architectural design, etc.), a growing number of building materials are being developed based on biomimicry, including adhesives, coloring agents, and coatings for bird-safe glass. The Biomimicry Institute provides information on the concepts, as well as ongoing implementation examples.

-

Social equity is gaining attention as an important material vetting consideration. The concept typically applies at the product manufacturer level, rather than at the product level, and addresses company operating policies and production processes from the standpoint of social health and equity.

Equity issues are often addressed in manufacturers' annual Environmental, Social and Governance (ESG) or Corporate and Social Responsibility (CSR) reports. Manufacturers typically report on specific initiatives undertaken or benchmarks achieved based on their internally-developed goals.

From the standpoint of third-party standards, a Supplier Code of Conduct in compliance with the International Labor Organization (ILO) conventions can be provided as evidence of a company's social equity commitments. The ILO code addresses eight fundamental issues organized under the following 4 headings:

- Equality (including Non-discrimination and Equal Renumeration)

- Freedom of Association

- Abolition of Forced Labor

- Elimination of Child Labor.

Currently, LEED offers a Pilot credit based on selecting products from companies that comply with the ILO conventions.

The Mindful Materials library includes a reporting section specifically on Social Health and Equity; however the reporting standard for this topic is still under development at the time of this report.

Also, the JUST disclosure tool developed by the International Living Future Institute (the same organization that manages the Living Building Challenge) is an initiative designed to help organizations of all types - including product manufacturers - report on social equity, diversity, employee heath and benefits, stewardship, and equitable purchasing. While the program has been adopted primarily by design professionals and construction firms, it is expected that more manufacturers will adopt the system over time.

-

- Develop advanced vetting and specification criteria:

-

While the specification tools noted in the Resources section provide a good starting point for developing green specifications, the types of advanced "deep dive" research reviewed in this section necessitate equally advanced specifications. Advanced vetting and specification criteria tend to be customized per product type, and often include refined listings of red list chemicals (those most applicable to the material at hand), embodied carbon limits, and maximum emission levels and/or VOC limits that are more stringent than the standards used in the green building rating systems. Additional bespoke criteria may also be developed to address issues ranging from product circularity to social equity reporting.

These types of specifications will continue to evolve as more information becomes available and more research is performed, and as manufacturers continue to refine their products and processes. It is likely that more sophisticated tools will also be developed over time to assist project teams in incorporating these more detailed and complex requirements.

-

Considerations at All Levels

Selecting environmentally preferable materials requires research, critical evaluation, and common sense. In addition to the various sustainability and wellness characteristics that are subject to review, traditional issues such as durability, code compliance, warranties, and the performance "track record" of green products (particularly newly introduced materials) must be carefully considered. Specifiers should expect that some green products may be subject to limited availability or long lead times. Finally, users should be wary of environmental claims (both positive and negative) that have not been substantiated by independent sources.

The most successful applications of environmentally preferable materials are those that extract multiple benefits from the products selected. With careful selection and analysis, products can be identified which combine attributes such as high durability and high use of recycled content (e.g., carpet tiles with recycled content fiber or backings, or reduced embodied carbon), or rapidly-renewable materials that also have low emissions (e.g., straw fiber board that is formaldehyde-free). When this combination of results occurs, the "green" material selection can potentially be more cost-effective than a typical product. This creates a win-win situation with other key product criteria.

Relevant Codes and Standards

- ASHRAE 189.1

- Executive Order 13693, "Planning for Federal Sustainability in the Next Decade"

- Executive Order 14057, "Catalyzing Clean Energy Industries and Jobs Through Federal Sustainability"

Tools and Resources

A wealth of information has been developed (and continues to be developed) pertaining to green building materials. To effectively evaluate and specify green products, designers and specifiers must familiarize themselves with a number of these resources. The topics below represent a wide range of green product information, from broad concepts (guiding principles that define sustainability goals for materials), to project specifics (product listings and specification guides).

The "Application" section above provides further guidance on how to assimilate this information into a workable materials selection process.

Guiding Principles for Sustainable Materials

Several organizations and private companies have defined principles based on the concept of sustainability to be used as long-term guidelines in the development of new or reformulated products. These guidelines define goals such as closed-loop recycling and the elimination of products with bio-accumulative toxins. Although there are limited products that currently meet the full sustainability goals of these programs, the criteria are useful for assessing current materials in comparison to an ideal, rather than in comparison to other available products. Examples of guiding principles can be found at:

- Building Green's 12 Product Rules

- Cradle-to-Cradle methodology

- GreenScreen methodology from Clean Production Action

- Living Building Challenge Materials Petal

- Six Classes Approach to reducing chemical harm

Life-Cycle Assessment (LCA) Tools

Related to, but not to be confused with life-cycle economics, LCA is a methodology for evaluating the environmental impacts of a material through its entire "life cycle"—from its initial production through to its eventual reuse, recycling, or disposal. LCA attempts to identify and quantify all relevant environmental impacts for materials so that comprehensive comparisons can be made. Although LCA reports are often complex and technical in nature, tools such as the following can be used:

- LCA process documents as defined through ISO Standards such as 14025, 14044, and 14071. These standards include sections on Product Category Rules, which help manufacturers define consistent LCA parameters for specific material types.

- Environmental Product Declaration (EPDs) which provide LCA data for individual products or material types.

- The Embodied Carbon in Construction Calculator (EC3), which includes a database of EPD-based information to allow for material comparisons.

- Whole building software tools used by the design industry including:

These programs allow design teams to build mock-ups of their building designs to understand which systems and materials have the greatest environmental impacts. Alternates can be run to assess the most effective paths to reduce embodied carbon and other environmental factors.

LCA should not be confused with Life-Cycle Cost Analysis (LCCA), although LCCA can be an integral part of a full life-cycle assessment. Life-Cycle Cost Analysis, which can take into consideration environmental costs, is explained in detail in the LCCA Resource Page linked above.

Green Building Rating Systems

Green Building Rating Systems establish overall environmental performance criteria for entire buildings, interiors, and communities. In the U.S., the leading national green building-rating system is Leadership in Energy and Environmental Design (LEED®) developed by the U.S. Green Building Council (USGBC). The current LEED v4.1 program is available online, with detailed support documents and training available from the USGBC. Additional green building rating systems in use which address green materials as part of the larger process and requirements include:

- Building Research Establishment Environmental Assessment Method (BREEAM)

- Enterprise Green Communities

- Fitwel

- Green Globes

- Living Building Challenge, a program of the International Living Future Institute

- The Sustainable SITES Initiative

- The WELL Building Standard, administered by the International WELL Building Institute

Green Product Standards

To consistently assure the environmental performance of certain material types, several public agencies and private organizations have developed green product standards. These standards define the specific green criteria for various material types. In some cases, a trademarked "green" label can be used for complying products.

Green product standards can range from government regulations and guidelines (e.g., the EPA Comprehensive Procurement Guidelines for recycled content in products) to industry guidelines (The Carpet and Rug Institute's Green Label Plus program for Carpets), to third party certification standards (e.g., Green Seal standards for paints, FSC standards for wood products, NSI Sustainability Standards for natural stone). Because of the detailed criteria spelled out in green product standards, many of them can also assist in the development of project specifications (see Specification Guidelines section below).

While green product standards outline important criteria for different material types, they typically do not review the performance and variations of individual products from specific manufacturers. Some green product standards, however, do include lists of sample products or manufacturers that meet their criteria.

See also:

- Product Certification Services, as defined below; and

- WBDG resource page Green Building Standards and Certification Systems.

Specification Guidelines

Once a green material has been evaluated and selected for a project, it is important to include clear and binding specification language in the construction documents. Some of the most widely-used A/E specification software includes sustainable material language, typically following criteria from the major sustainability rating systems such as LEED.

Green Products Databases

This information profiles individual products from specific manufacturers. Green Material Databases provide listings of available products (typically organized by CSI Sections) with the environmental attributes claimed by the manufacturers.

- EPA Comprehensive Procurement Guidelines—A key component of the government's "buy-recycled" program, the EPA's CPG provides information, specification criteria, and manufacturer's lists for a wide range of recycled content products.

- EPA Environmentally Preferable Purchasing Program—Helps federal agencies procure greener products and services and harness federal purchasing power to green markets.

- GSA Federal Acquisition Service

- Mindful Materials—This Library aggregates product sustainability information while minimizing redundant effort on the part of both manufacturers and designers.

- Sustainable Facilities Tool—Green Procurement Compilation

- UL Environment / UL Spot—Helps businesses align sustainability management and strategic direction and make it easier to track, measure, and share sustainable performance metrics with stakeholders.

Product Certification Services

- Cradle to Cradle (C2C)

- Declare

- Forest Stewardship Council United States (FSC)

- GreenScreen Certified

- GreenSeal

- SCS Global Sevices

Other

- AIA 2030 Materials Pledge

- Biomimicry Institute—Products inspired by nature's genius

- Building Green—A trusted source that helps architects, designers and other sustainability professionals make their projects greener and healthier.

- Construction & Building Materials Directory by Sweets™—Provides manufacturer's product information on numerous construction products.

- GSA Sustainable Facilities Tool (SFTool)—SFTool's immersive virtual environment addresses all your sustainability planning, designing and procurement needs.

- Health Product Declaration Collaborative—The organization that develops and administers Health Product Declarations (HPDs) for the building industry. HPDC has been instrumental in defining the detailed, rigorous, and independent HPD protocol, which provides a consistent format for reporting chemical content and health-related hazards in building products. The HPDC also hosts a repository of thousands of HPDs which can be searched and downloaded.

- Healthy Building Network

- Pharos