Introduction

Within This Page

- Introduction

- Description

- Application

- Operation and Maintenance

- Special Considerations

- Additional Resources

THIS PAGE SUPPORTED BY THE

Biogas is the gas produced by the biological breakdown of organic materials. Fermentation, or anaerobic digestion, is the most common process that breaks down the organic materials. The organic materials are then oxidized and create energy, which dates back to ancient Persians who observed that rotting vegetables produce flammable gas. Anaerobic digestion is a process that uses microorganisms to break down the organic material in the absence of oxygen, which creates energy. An anaerobic digestion plant was built to process sewage in Bombay in 1859, and has been used in the United Kingdom since 1895.

The types of organic materials include biomass, landfill waste, sewage, manure, and plant material. The most common gases produced are methane and carbon dioxide. Other common gases that can be formed include hydrogen, nitrogen, and carbon monoxide. Methane, hydrogen, and carbon monoxide can be combusted to create heat and electricity. When biogas is created from existing waste streams, it reduces odors and methane emissions and creates two renewable resources. Sewage sludge and animal slurries usually end up as fertilizer, so it is better to obtain fuel from them first, while preventing runoff and methane emissions at the same time. Biogas is not a widely used renewable energy technology for most new construction or major renovation projects since most buildings do not have a large source of organic material. However, projects located near a landfill or contained animal feeding operation may want to consider this option since it can provide low-cost energy.

Methane is a very potent greenhouse gas—more than 21 times stronger than carbon dioxide—and is a key contributor to global climate change. The U.S. Environmental Protection Agency (EPA) Landfill Methane Outreach Program estimates that a landfill gas energy project will capture roughly 60% to 90% of the methane emitted from the landfill, depending on system design and effectiveness. As of December 2010, there are 541 operational landfill gas energy projects in the United States and approximately 510 landfills that are good candidates for projects.

This overview is intended to provide specific details for Federal agencies considering biogas technology as part of a major construction project. Further general information is available through the U.S. Department of Energy (DOE) Office of Energy Efficiency and Renewable Energy (EERE) Anaerobic Digestion Energy Basics.

Description

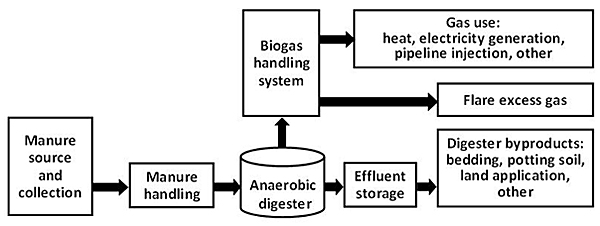

There are two primary methods of recovering biogas for use as energy. The first process is to create an anaerobic digestion system to process waste, most commonly manure or other wet biomass. The second process is to recover natural biogas production formed in existing landfills. Once recovered, biogas can be converted to energy in a number of methods.

Anaerobic Digestion

An anaerobic digestion system is made up of several key components, including:

- Manure collection systems

- Anaerobic digesters

- Biogas handling systems

- Gas use devices.

A manure collection system is needed to gather manure and transport it to the digester. Existing liquid/slurry manure management systems can readily be adapted to deliver manure to the anaerobic digester. Anaerobic digesters, commonly in the form of covered lagoons or tanks, are designed to stabilize manure and optimize the production of methane. A storage facility for digester effluent, or waste matter, is also required. In the biogas handling system, biogas—a product of the decomposition of the manure, typically comprising about 60% methane and 40% carbon dioxide—is collected, treated, and piped to a gas use device. Biogas can then be used to generate electricity, as a boiler fuel for space or water heating, upgraded to natural gas pipeline quality, or for a variety of other uses. Flares are also installed to destroy extra gas and as a back-up mechanism for the primary gas use device.

The stages of the anaerobic digestion process.

Anaerobic digesters are made out of concrete, steel, brick, or plastic. All anaerobic digestion system designs incorporate the following same basic components:

- A pre-mixing area or tank

- A digester vessel

- A system for using the biogas

- A system for distributing or spreading the effluent.

Batch digesters and continuous digesters are the two basic types of anaerobic digesters. Batch-type digesters are the simplest to build. Their operation consists of loading the digester with organic materials and allowing it to digest. The retention time depends on temperature and other factors. Once the digestion is complete, the effluent is removed and the process is repeated.

In a continuous digester, organic material is constantly or regularly fed into the digester. The material moves through the digester either mechanically or by the force of the new feed pushing out digested material. Unlike batch-type digesters, continuous digesters produce biogas without the interruption of loading material and unloading effluent. There are three types of continuous digesters: vertical tank systems, horizontal tank or plug-flow systems, and multiple tank systems.

Proper design, operation, and maintenance of continuous digesters produce a steady and predictable supply of usable biogas, which is better suited for large-scale operations.

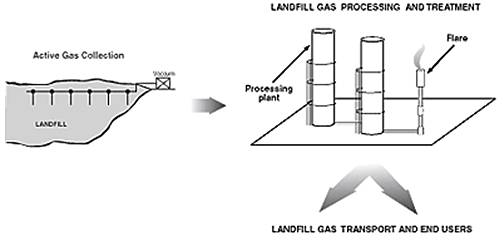

Landfill Gas Recovery

A landfill gas treatment station with blower and flare.

The same anaerobic digestion process that produces biogas from wastewater and animal manure occurs naturally underground in landfills. The waste is covered and compressed by the weight of the material that is deposited above. This material prevents oxygen exposure, thus allowing chemical reactions and microbes to act upon the waste, and encouraging an uncontrolled process of biomass decay. The rate of production is affected by waste composition and landfill geometry. Landfill gas is about 40% to 60% methane, with the remainder consisting mostly of carbon dioxide.

Landfill gas is extracted from landfills using a series of wells and a blower/flare system. According to the Landfill Methane Outreach Program, the system directs the collected gas to a central point where it can be processed and treated depending upon the ultimate use for the gas. A landfill gas collection system includes the following components:

- Landfill gas well

- Landfill gas wellhead

- Landfill gas processing and treatment

- Landfill gas flare.

Diagram of a landfill gas system.

Application

Biogas is most efficiently used in heating applications since the heat from combustion can be directly used. This requires the site to have a constant heating load throughout the year, which is common in building types such as hospitals and residential buildings. Biogas can also be used to operate a fuel cell or generator in order to make electricity. Where a facility does not have a consistent year-round heating load, such as a hospital or residence, electricity production may be the most valuable use of biogas.

Biogas can also be used for commercial electricity generation and direct combustion. Commercial electricity generation systems that use biogas consist of an internal combustion engine, a generator, a control system, and an optional heat recovery system. In addition, fuel cells can make use of biogas for electricity production. Direct combustion of biogas on-site in a boiler or forced air furnace can provide seasonal heat to facilities. More information on these applications is available from the Renewable Energy Institute.

See the Fuel Cells Resource Page for additional information on fuel cells.

Anaerobic Digestion

Farms and ranches are common places where anaerobic digestion can make sense since there are typically large quantities of organic material available. Digesters effectively eliminate the environmental hazards of dairy farms and other animal feedlots. The environmental reasons typically motivate farmers more often than the digester's electrical or thermal energy generation potential does. Other potential common uses are zoos or any facility located near a continuous source of biomass such as a contained animal feeding operation.

EPA's AgSTAR program provides an array of information and tools designed to assist producers in the evaluation and implementation of these systems. In general, the system needs to be large, such as a contained animal feeding operation or a zoo. Federal agencies located near such facilities may want to investigate the possibility of a partnership to provide ongoing biogas to the facility.

Landfill Gas Recovery

When a Federal facility is located adjacent or near a landfill with either an existing gas recovery system or with the potential for landfill recovery, the agency may want to investigate the potential of a partnership with the landfill or work with a developer to create a biogas recovery process that would provide reliable renewable gas to the Federal facility.

Economics

The following economic factors should be considered for anaerobic digestion and landfill gas recovery systems.

Anaerobic Digestion

Anaerobic digester system costs vary widely, especially since these types of systems can be put together using off-the-shelf materials. There are also a few companies that build system components. The design of these systems is critical, and they need to be carefully designed by experts to ensure that the process will actually digest the waste material under various operating conditions at the site. Before installing an anaerobic digester—also known as a biodigester—on a farm or ranch, it is recommended that the system's economic value and potential benefits be explored.

A biodigester usually requires manure from more than 150 large animals to generate electricity in the most cost-effective way. Anaerobic digestion and biogas production can also reduce overall operating costs where costs are high for sewage, agricultural, or animal waste disposal.

In the United States, the availability of inexpensive fossil fuels has limited the use of digesters solely for biogas production. However, the waste treatment and odor reduction benefits of controlled anaerobic digestion are receiving increasing interest, especially for large-scale livestock operations such as dairies, feedlots, and slaughterhouses. In many cases, the economics of a system are not based on lowest energy cost; but if a project can combine the on-farm benefits of a digester with a long-term contract for the biogas, the economics may make sense to either a farm or a developer.

Landfill Gas Recovery

As stated by EPA's Landfill Methane Outreach Program, current regulations under the Clean Air Act require many larger landfills to collect and combust landfill gas. There are several compliance options, including flaring the gas or installing a landfill gas use system. Only landfill gas energy recovery gives communities and landfill owners the opportunity to reduce the costs associated with regulatory compliance by turning pollution into a valuable community resource.

Again, the available energy may not be the driving force behind landfill gas recovery, but partnership with a Federal agency that is able to provide a long-term use for the biogas could improve the economics of this type of system.

Assessing Resource Availability

For either an anaerobic digestion or landfill gas recovery system, the following resources need to be assessed.

Anaerobic Digestion

Biogas recovery systems are technically feasible where manure is handled in a liquid, slurry, or semi-solid state, whereas digester systems are technically feasible only on certain farms. The number of animals and the type of manure management system are crucial. Anaerobic digesters are most adaptable to farms that collect large amounts of manure as a liquid or slurry. To determine if a biogas recovery system is right for a specific facility, the following factors must be considered:

- How is the facility's manure handled?

- What is the frequency of manure collection?

- What are the options available for using the recovered biogas?

To find out more information about whether a biogas recovery system is feasible for a specific facility, visit EPA's AgSTAR program.

Landfill Gas Recovery

The key points that need to be investigated to determine whether landfill gas capture is feasible are the age of the landfill, the size, and the types of gases generated. For landfill gas capture, it is best to have a newly capped landfill because the landfill gas production greatly declines after 20 to 30 years. The types of gases that are generated by the landfill can be determined by doing the following test: drilling a hole into the landfill, putting a vacuum on the landfill, and sampling the rate and types of gases being generated. A detailed landfill gas study should be done in order to determine the feasibility of landfill gas use. The EPA estimates that there are approximately 6,000 landfills in the United States. To see where all the existing tapped and candidate landfills are located, visit EPA's Landfill Methane Outreach Program. The website also includes a Landfill Gas Energy Benefits Calculator to estimate direct, avoided, and total greenhouse gas reductions for a particular project.

Procurement Considerations

The following issues should be addressed before a landfill gas request for proposal is issued: public versus private ownership, law and policy, potential financial and non-financial benefits to the municipality, required and available resources, and a preliminary feasibility analysis. Procurement risks include too little or too much value to the municipality, capital and operating costs, access to debt and equity capital, access to Federal grant or Federal investment tax credit, sales prices of Renewable Energy Credits and electricity, and monetized value of carbon credits.

Typically, the source of biogas will not be on Federal property, and a separate ownership arrangement for the biogas system will be warranted. The agency should investigate various renewable energy project funding options for the project.

The Federal Energy Management Program (FEMP)'s Guide to Integrating Renewable Energy in Federal Construction has more information on renewable energy project funding.

Operation and Maintenance

For small-to-medium-sized digesters with electrical generators, operation and maintenance (O&M) costs include daily operator labor to perform routine maintenance and pump the manure. Other factors include expenses for engine oil changes and minor repairs, and maintenance such as engine overhauls and sludge removal. Annual O&M is estimated at 3% of the digester system turnkey cost.

O&M costs for a landfill gas collection system are approximately $25 per acre per month. This accounts for miscellaneous parts, replacements, monitoring, and labor for O&M of the gas collection system.

Special Considerations

The following are important special considerations for biogas systems.

Interconnection

A biogas system that will be used for power production will need to be connected to the local utility grid and must meet interconnection requirements of the local utility. Many states or localities have guidelines that require interconnection of many customer-owned power projects. Some guidelines limit the size of a project that can be interconnected, or place a grid-wide limit on the amount of capacity a utility must interconnect. The local utility for the site is the best resource for interconnection rules.

A Federal agency should confirm early in the discussion with the utility if it can sign the utility interconnection agreement as there have been some cases where utility indemnification clauses prevented an agency from legally signing the agreement.

The Database of State Incentives for Renewables & Efficiency (DSIRE) is a comprehensive source of information on state, local, utility, and Federal incentives and policies that promote renewable energy and energy efficiency.

Environmental Review / Permitting

If the project is located on Federal land or uses Federal funding (besides a tax credit), it must comply with the National Environmental Policy Act (NEPA). Although both anaerobic digestion and landfill gas recovery systems have a net positive effect of removing harmful emissions from the air, they can still face issues with NEPA review. However, if the projects are not on Federal lands and are not owned by the agency, the NEPA process may not be required for certain systems. Consulting with an agency environmental expert on procedures for implementing NEPA is recommended.

Additional Resources

The Renewable Energy Institute has additional information and resources on biogas technologies.

Anaerobic Digestion

The EPA's AgSTAR program is a voluntary outreach and educational program that promotes the recovery and use of methane from animal manure.

Landfill Gas Recovery

The EPA's Landfill Methane Outreach Program (LMOP) is a voluntary assistance program that helps to reduce methane emissions from landfills by encouraging the recovery and beneficial use of landfill gas as an energy resource.