Introduction

Within This Page

While the large majority of energy used in the United States still comes from fossil fuels (see EIA for example), there is also tremendous growth in alternative and renewable energy technologies. In this context, alternative energy refers to energy not derived from traditional fossil fuel sources (coal, natural gas, petroleum) through conventional processes. Renewable energy is a subset of alternative energy; according to the National Renewable Energy Laboratory (NREL), "Renewable energy resources—such as wind and solar energy-are constantly replenished and will never run out."

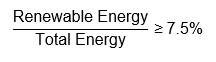

Both market and regulatory forces are driving increased adoption of renewable energy. The Energy Policy Act of 2005 (EPACT), for example, calls for federal agencies to obtain at least 7.5% of their electricity from renewable sources. To stimulate development of new renewable energy projects, Executive Order 13693 requires federal agencies to explore on-site renewable energy generation at their facilities. Many states around the nation have implemented renewable portfolio standards (RPS) mandating a minimum fraction of renewably generated energy in all electricity sold. The Database of State Incentives for Renewables and Efficiency (DSIRE) has information on some of these RPS's.

In conjunction with regulatory requirements for renewable energy, costs of fossil fuels remain rather high and costs of some renewable and alternative energy technologies are coming down. This article focuses on several such energy sources, with a primary focus on electricity generation. The practical use of these systems varies with the specific technology, application, location, cost of energy, and other factors. While many of the technologies are becoming more cost-effective, alternative energy generation is not a substitute for reliable energy efficiency strategies. Implementing efficiency strategies first is still the best approach to meet most energy goals.

Description

Wind

For centuries, people have harnessed energy in the wind—historically this has been used as mechanical energy for milling or water pumping. Wind-powered water pumps are still used in remote areas of the U.S., but harnessing the wind to generate electric energy has become much more common. In modern wind turbines, kinetic energy in the wind is converted to rotational energy and then to electrical energy. This electricity is then conditioned and—in most cases—sent into the utility grid.

In some parts of the country, wind energy has become cost-competitive with conventional sources of electricity generation. There are a growing number of wind generators available with capacities ranging from a few hundred watts (powering small off-grid homes, sailboats, etc.) to several megawatts (for utility-scale generation). The physical size of these generators has a similar range&mdsh;diameters from 3–4 feet to 300–400 feet.

Wind generators are certainly most effective in areas with consistent, high-speed winds. Trees, buildings, and topography can slow winds down tremendously. In the United States, the best wind resources are generally near the coasts (off-shore) or on the Plains. DOE, NREL, and others have developed wind resource maps for the country and some states have developed more detailed maps.

Proper location of wind turbines is critical. Because there can be wide variations in wind speed over small distances, best practices often call for monitoring wind resources at a site (or several potential sites) for a year or more. With smaller generators (several kilowatts), turbines should typically be mounted 30–50 feet above the next highest object in a 500-foot radius (trees, buildings, etc). Larger generators are centered 100 feet or more off the ground where wind speeds are higher and less turbulent.

Because most electric energy is used in buildings, many people have explored mounting wind turbines on top of buildings. This is often not a viable strategy because of the weight, vibrations, torque, and noise of the generators. To get access to higher wind speeds, generators should be positioned well above nearby buildings. There are some wind generator products, however, specifically designed for mounting on buildings. They are usually small (typically 2000 Watts or less) and are still subject to wind speed and turbulence limitations.

Wind turbines mounted on an apartment building in the Bronx, New York

Photo credit: Steven Winter Associates, Inc.

A wind turbine at a Massachusetts school

Photo Credit: Northern Power Systems

While small, building-mounted turbines can be appealing to designers, larger turbines (located far above buildings and other obstructions) are much more effective with respect to electricity generation.

Biomass

Biomass power generation typically refers to the combustion of plant material to power turbines which—in turn—generate electricity. The term biofuel generally refers to a fuel derived from plant material (biomass) that can be used in lieu of conventional fossil fuels.

An efficient wood stove in a new home

Photo Credit: Steven Winter Associates, Inc.

The oldest use of biomass energy is burning wood to keep warm. This is still quite common in homes today, and there are also more advanced boiler systems that burn wood to heat water for use in homes or larger buildings. Some of these devices are designed to burn wood pellets rather than larger pieces of wood. Wood pellets are small (less than one inch) pieces of processed biomass from a variety of sources (wood chips, sawdust, waste from wood processing, etc.) Pellet-burning appliances typically have hoppers that feed the fuel to the firebox at a controlled rate—making pellet burning easier to control than some other types of biomass appliances. More information on this and other wood burning technologies for buildings is available through ENERGY.GOV Energy Saver pages.

On larger scales, many timber and agricultural industries burn wood and agricultural waste to obtain useful heat—the heat can be used directly or used to power turbines to generate electricity. When the biomass fuel is inexpensive—especially when it is a waste product—such power generation can be very cost-effective.

As with burning of fossil fuels, burning biomass releases carbon dioxide and other pollutants. Because the carbon in biomass has quite recently been absorbed from the atmosphere, if the biomass resource is managed sustainably there may be little net-emissions of carbon dioxide. This closed carbon cycle, however, does not necessarily include any energy needed to cultivate, harvest, and process the biomass. In addition to pollutants, opponents of biomass generation cite potential effects on regional agriculture or forestry. With growing demand for biomass, there may be pressure to harvest resources in less sustainable ways.

Biofuels

Fuel pump with 20% biodiesel (B20), 85% ethanol, and standard unleaded fuel with 10% ethanol.

Photo Credit: Charles Bensinger and Renewable Energy Partners of New Mexico

As described above, biofuels are fuels derived from biomass that can be used in place of conventional fossil fuels. The two most common biofuels are ethanol and biodiesel. Ethanol is currently used in gasoline mixtures to power many automobiles. Most of this ethanol comes from the fermentation of sugars found in food crops, primarily corn. Federal incentives make this cost-effective, but there is growing concern that using ethanol derived from fermentation of corn sugars is not sustainable; there may be more energy needed to cultivate, harvest, and process the material than is contained in the final fuel produced. Other ethanol production strategies—using cellulosic material rather than sugars—can derive ethanol from wood chips, leaves, agricultural waste, and similar material. These show promise with respect to sustainability, but they currently have substantially higher costs (see EERE Newsletter for more information).

Biodiesel is made by converting natural oils—usually vegetable oils—into usable fuels. The fuel can be used in many engines or combustion appliances designed for diesel or no. 2 fuel oil. The appliances typically need no or minor adjustments, though sometimes a blend of biodiesel and petroleum results in best operation. The manufacturing process is well understood and quite environmentally benign. The chief limitation of biodiesel manufacture is a cost-effective, sustainable source of vegetable oils.

Waste oils were one of the first targets for biodiesel manufacturers. In some areas, restaurant managers—who used to pay substantial fees to dispose of waste cooking oils—found new consumers who were willing to take waste oil at no charge, or even to pay for the used oil. While truly sustainable, such waste oil results in a very small volume of biodiesel. Most fuel is generated from virgin vegetable oils, especially oils from soy or rapeseed. Most experts agree that biodiesel manufacture is much less energy-intensive than conventional ethanol production—i.e. much less energy is used to create the fuel than is contained in the final fuel product.

Solar Energy

Solar energy systems in buildings include systems that capture heat (such as solar water heating systems and passive heating), and systems that convert solar energy into electricity. The latter is done primarily through photovoltaic (PV) systems. PV technology has seen dramatic improvements—and cost reductions—since its first applications in the space program in the 1960's. While the technology is still not inexpensive, from 2006 to 2010, installed costs of PV systems have dropped 30–40%. This drop—combined with higher energy costs, government and/or utility incentives, and time-of-use electric rates—have made PV cost-effective in a growing number of applications.

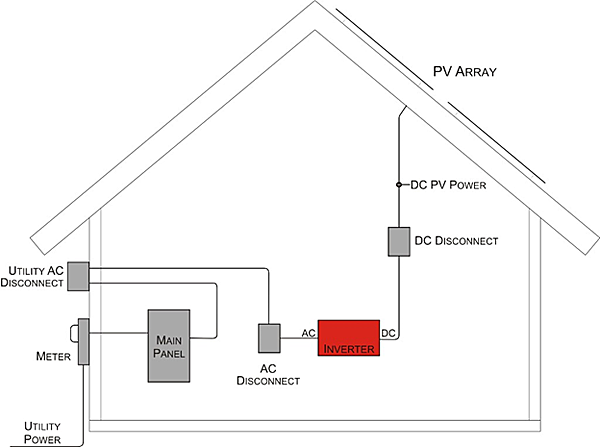

The heart of PV technology is in the semi-conductors (mostly silicon-based) used in the PV modules themselves. The modules convert sunlight to direct current (DC) energy; the DC energy is typically then converted to alternating current (AC) energy via inverters. From the inverters, energy is typically fed into a building's electric system or exported to the utility grid.

Simple schematic showing the main components of a PV system and how it is typically incorporated into a building—in this case a home.

The amount of electricity that a PV system generates depends upon the amount of sun received and many other installation parameters (tilt, orientation, shading, etc.). A simple and accurate tool for predicting generation is PVWatts, developed by NREL.

As PV collectors need direct sun, they are often mounted on roofs. While not extremely heavy, structural factors must be taken into account in planning a roof-top installation. Designers need to be aware of mounting requirements, ballast, and wind loads. Any roof penetrations (for mounting or electrical) need to be planned for and detailed properly. Panels should face south (in the northern hemisphere) and shade (from trees, other buildings, roof-top equipment, etc.) should be minimized. In some cases, PV collectors can be incorporated as part of the roof or building envelope; see the Building-Integrated Photovoltaics page for more information.

While most PV collectors are mounted in stationary positions, some free-standing arrays use devices to track the path of the sun across the sky. This can increase electricity generation substantially (20% or more), but it also adds cost and complexity to the system. PV modules themselves are very durable and have no moving parts; most warrantees are 20–30 years. Inverters are usually shorter-lived; these warrantees are typically 5–10 years.

PV system on a mail processing center in Los Angeles. PVs are one of the most reliable renewable energy technologies, and building integration can be straightforward.

Photo Credit: Bill Golove

PVs can also be mounted on the ground or auxiliary structures. These collectors provide shade for parked cars at MCAS Miramar.

Photo Credit: MCAS Miramar

Geothermal

Temperatures at the bottom of the Earth's crust—some 5–40 miles below the surface—are typically over 1000°F. In a few locations, these high temperatures reach closer to the surface resulting in volcanic activity, hot springs, geysers, and the opportunity for geothermal electricity generation. Geothermal plants tap relatively shallow pockets of steam; the steam is used to operate turbines that generate electricity.

Clearly, geothermal generation is very location dependent. According to Department of Energy sources, there is approximately 3,000 MW of geothermal electricity generation capacity in the United States. Researchers say, however, that there is potential for 100,000 MW of generation using the latest technologies. At some locations where the accessible geothermal resources are not at sufficient temperature to generate electricity cost-effectively, the heat can be used directly (for industrial processes, space heating, etc.) In the United States, nearly all generators—and most potential sites—are located in the western part of the country (see map).

The term "geothermal" is also sometimes used to refer to ground source heat pumps (GSHPs). While not a means of generating renewable energy, GSHPs can be part of an efficient HVAC system.

Cogeneration

When a fuel—fossil-based or otherwise—is converted to electricity, there is also a substantial amount of heat generated. Usually the quantity of heat generated is far greater than the quantity of useful electricity; typically 30–40% of energy in a fossil fuel is converted to electricity using conventional technologies. Cogeneration or combined heat and power (CHP) is a strategy whereby both useful heat and electricity are obtained from processing a fuel.

These cogeneration units provide electricity to meet some of the base load in a New York City apartment building. While the up-front and maintenance costs are significant, the cost of the natural gas used to generate electricity is less than the cost of electricity purchased from the utility. The thermal energy the engines provide—used for water heating—results in additional natural gas savings of over $10,000 per year.

Photo Credit: Steven Winter Associates, Inc.

The concept itself is not new. For nearly as long as people have been burning fuel to generate electricity, people have been looking for ways to utilize the excess heat generated. Newer technologies, combined with higher energy rates, allow smaller-scale, distributed cogeneration to be more cost effective in some buildings or campuses.

Cogeneration is a strategy that includes many types of distributed generation technologies such as turbines, micro-turbines, reciprocating engines, and fuel cells. The most common fuel for these cogeneration technologies is natural gas. A great deal of ongoing research and development focuses on hydrogen fuel cells, but most hydrogen is also currently derived from natural gas. While cogeneration can be considered an alternative energy technology, it is not renewable when it relies on fossil fuels.

Cogeneration is most effective where both electrical and thermal loads are predictable, steady, and coincident. For example, thermal demands for space heating in the winter and electrical demands for space cooling in the summer are not a good match for cogeneration. At the same site, however, there may be steady, year-round thermal loads (e.g. service water) and baseline electrical loads (lighting, equipment, HVAC base loads, etc.). It is possible that a properly sized cogeneration system could cost-effectively meet the base loads while additional heat and electricity would be obtained at lower cost from conventional sources. An accurate knowledge of load patterns—both thermal and electric—is key in designing a good cogeneration system.

Hydropower

Hydropower is one of the oldest and most prevalent renewable energy technologies, accounting for over 10% of all U.S. electricity in 1996 (EIA). By 2009, however, this fraction dropped to below 7%. Hydropower generation itself dropped 22% over this period. While certainly renewable, conventional hydropower is often not sustainable. The effects of dams on river ecologies are frequently dramatic, and working dams have been removed in an attempt to restore riparian ecosystems.

A beta hydrokinetic generator to be installed near Eastport, ME—location of some of the largest tides in the U.S.

Photo Credit: Ocean Renewable Power Company

While it is possible to create sustainable hydropower systems in rivers, these systems tend to be smaller (see EERE resources for more information). Hydropower generation is also moving away from dams towards hydrokinetic systems—systems that use the natural flow of water rather than damming or diverting flow through conventional turbines. There are many types of emerging hydrokinetic technologies; some are designed for rivers, some for ocean areas with strong tidal flows, and some designed to harness energy in ocean waves.

Application

While many alternative energy technologies are becoming more viable and affordable, renewable energy is still often much more expensive than energy efficiency; it is usually much less expensive to save energy than to generate renewable energy. The most cost-effective route to meet the EPAct (or other) renewable energy goals will likely include both increasing the numerator (renewable energy) as well as decreasing the denominator (total energy) in the renewable energy fraction equation:

Understanding total energy use at a facility is also important when exploring appropriate alternative energy systems. Cogeneration systems, for example, should be sized to meet consistent electrical and thermal loads in order to be practical and cost-effective. If power used for space cooling represents a large expense, a PV system sized to reduce this peak can translate into more significant cost savings.

During planning of alternative generation systems, it is critical to consider integration into existing electrical systems and/or the utility grid. Requirements for utility interconnection vary state-by-state and often utility-by-utility. Links to several state regulations can be found at DSIRE; check with local utilities and/or regional authorities for specific permitting and interconnection requirements.

Site considerations are also important during planning. In addition to the obvious (e.g. PV systems should not be shaded, wind turbines should have access to consistent winds), designers should consider aesthetic and noise impacts of the technologies.

Finally, in planning for alternative energy systems, consider ongoing operation and maintenance requirements. O&M requirements for these technologies vary widely. In addition to the costs, make sure the facility or staff has the resources needed to keep the systems operating at peak performance.

Relevant Codes and Standards

- Biodiesel Handling and Use Guide

- Energy Policy Act of 2005 (EPACT)

- Executive Order 13693, "Planning for Federal Sustainability in the Next Decade"

- NFPA 70 National Electric Code®

- North American Board of Certified Energy Practitioners

Additional Resources

Organizations

- American Wind Energy Association

- Geothermal Energy Association

- Geothermal Resource Council

- International Hydropower Association

- National Biodiesel Board

- CHP Association

- Evergreen Solar (National Council for Solar Growth)

Others

- Database of State Incentives for Renewable Energy (DSIRE)

- DOE–EERE Bioenergy Basics

- DOE–EERE Alternative Fuels and Advanced Vehicles

- DOE–EERE Geothermal Technologies Office

- DOE–Marine Energy Projects Database

- DOE–EERE Microhydropower Systems

- NREL Biomass Energy Basics

- PVWatts® Calculator

- Wind Resource Data, Tools, and Maps