Introduction

Within This Page

A typical laboratory currently uses five times as much energy and water per square foot as a typical office building. Research facilities are so energy demanding for a variety of reasons:

- They contain large numbers of containment and exhaust devices;

- They house a great deal of heat-generating equipment;

- Scientists require 24–hour access; and

- Irreplaceable experiments require fail-safe redundant backup systems and uninterrupted power supply (UPS) or emergency power.

In addition, research facilities have intensive ventilation requirements—including "once through" air—and must meet other health and safety codes, which add to energy use. Examining energy and water requirements from a holistic perspective, however, can identify significant opportunities for improving efficiencies while meeting or exceeding health and safety standards. Sustainable design of lab environments should also improve comfort and worker productivity.

Chilled beams are an excellent opportunity to use new technology to reduce air change rates but not jeopardize safety. NIH conducted a two year study and determined that chilled beams were the best value for the second phase of their neuroscience facility. The image to the right is from Oklahoma Medical Research Facility (OMRF) with chilled beams installed. The square shaped panel in the ceiling is the chilled beam.

Another approach gaining popularity in the last few years is a chemical sensor system to manage air change rates more efficiently. The Texas Children's Hospital has been up and running since the beginning of 2011. With the chemical sensors the entire building as been running at slightly less than 4 air change rates for the entire year This is a significant savings and the cost of the system had a payback of slightly less than a year.

Description

The key aspects of sustainable laboratory design include:

- Increased energy and water conservation and efficiency

- Reduction or elimination of harmful substances and waste

- Improvements to the interior and exterior environments, leading to increased productivity

- Efficient use of materials and resources

- Recycling and increased use of products with recycled content

See WBDG Sustainable Branch for more details on the principles of sustainable design.

The following table is an example of a sustainable design criteria chart set up for a specific laboratory project. Each criterion must be reviewed for each specific project.

| Sustainable Design Criteria | ||||

|---|---|---|---|---|

| Parameter | Code Minimum | Code Reference | Standard Practice | Design Target |

| Ventilation | 10 cfm/person | ASHRAE 62/89 | Same | Maximize outdoor air in thebreathing zone |

| Filtration | none | 35–80% | 65% pre filter 85% final filter |

|

| Indoor Design Temperature | 75° F summer 72° winter |

Same | ||

| Humidity Control | uncontrolled | uncontrolled | 60% RH summer 40% RH winter |

|

| Equipment Heat Dissipation | NA | 3-4W/sf | 1.5W/sf or 2W/sf with 75% diversity factor | |

| Toilet Exhaust | 50 cfm/fixture | ASHRAE 62/89 | Same | 2 cfm/sf |

| Connected Lighting Heat Load | NA | 2W/sf | 0.5–0.75W/sf Total task/ambient with occupancy sensors and daylight sensors |

|

| Lighting Levels | 100 ft. candles all direct | Same | 20-30 ft. candles with ambient and task lighting | |

| Building Shell Infiltration | 6"/100 sf | ASHRAE guideline | 3"/100 sf | 1.5"/100 sf (Canadian Standard) |

| Building Shell Infiltration (alternate) | 0.60 cfm/sf | ASHRAE guideline | 0.30 cfm/sf | 0.10 cfm/sf |

| Exterior Wall Insulation | U = 0.28 btu/sf-hr-F | BOCA Energy Code | 0.10 btu/sf–hr-F | U = 0.15 btu/sf–hr South U = 0.05 btu/sf–hr (N, E, W) |

| Exterior Wall Moisture Control | none | AIB - with insulation both sides | ||

| Roof Insulation | U – 0.07 btu/sf–hr | BOCA Energy Code | U – 0.05 btu/sf–hr– F | U – 0.05 btu/sf-hr– F with low albedo surfacing |

| Windows | ||||

| Glazing type | Single/clear | Double/clear | heat reflecting clear | |

| Visible transmittance | 0.80 | 0.78 | 0.70 | |

| Shading Coefficient | 1.00 | 0.80 | 0.43 | |

| U value | 1.04 | 0.48 | 0.30 | |

| Heat Degree Days | 6,155 btu | ASHRAE | Same | Determined by DOE-2 or otherenergy analysis of TMY data |

A. Architectural Considerations

The design of the building envelope—including overhangs, glazing, insulation, and (possibly) the use of photovoltaic panels—plays a large role in the research facility's energy efficiency.

The stepped design at CDC Building 110 Facility provides overhangs and light shelves to shade and direct natural light into the office spaces inside.

Overhangs

Overhangs for shading windows are often designed as part of the wall system to improve the quality of the natural light entering the interior space. The south elevation should have a horizontal overhang; east and west elevations usually require both horizontal and vertical overhangs. See also WBDG Sun Control and Shading Devices.

Glazing

The glazing material for exterior windows should have a thermal break and an insulating section between the inner and outer sections of the frames. Wood or fiberglass frames will give much better thermal performance than aluminum. Low-E windows with at least an R-3 insulation value should be used. "Superwindows" that incorporate multiple thin plastic films can have an R value as high as 12. The problem is that such windows cost up to four times as much as low-E glass. Operable windows generally will not reduce energy costs; in fact, they may increase energy usage, but they usually enhance the quality of the indoor environment and are therefore preferred by most clients. See also WBDG Windows and Glazing.

Roofs and Walls

The use of light-colored roofing with a high-albedo coating to reflect light and heat is recommended. The amount of wall and roof insulation needed will vary depending on the climate and the type of lab. For example, equipment-intensive labs will generate a lot of heat and in certain parts of the country will not require as much roof insulation as elsewhere. All electrical outlets and all plumbing and wire penetrations into the building should be sealed, since air leakage can be a significant source of energy waste as well as moisture problems in some parts of the country.

Today, there is quite a bit of discussion about using photovoltaic panels both to enclose a building and to generate electricity. Photovoltaic panels can be integrated into the building envelope as metal roofing, spandrel glazing, or semi-transparent vision glazing. See WBDG Building Integrated Photovoltaics (BIPV) But the panels are difficult to justify in traditional applications because the electricity they generate can cost more than electricity purchased from the grid.

B. Engineering Considerations

Sustainable engineering addresses civil engineering concerns as well as the design of mechanical, plumbing, and lighting systems. First and foremost, the design team and client should contact the local utility company to explore opportunities for rebates to assist in the purchase of high-efficiency equipment or the implementation of other energy conservation measures.

Civil Engineering

Civil engineering issues to consider include the use of pervious materials and light colored wherever possible. In preparing a site for new construction, designers should consider transplanting existing trees instead of removing them. Proper storm water management strategies are also important to reduce erosion and replenish local aquifers. See also WBDG Sustainable—Optimize Site Potential and Achieving Sustainable Site Design through Low Impact Development Practices.

Mechanical, Plumbing, and Water Conservation Strategies

For the HVAC system, it is most important to simulate the operation of the whole system and to analyze assumptions using whole-building systems analysis software such as DOE-2. See also Laboratories for the 21st Century: Energy Analysis. Reducing building loads is critical to improving energy efficiency, and one key way to reduce loads is to reduce the amount of outside air used for ventilation. This raises a design challenge, however, since air supplied to laboratories is exposed to chemical contaminants and therefore cannot be returned to the central air handling system and must be exhausted. The volume of ventilation air required for the laboratories is typically greater than that for classrooms, lecture halls, and offices. One strategy to utilize outside air efficiently is to install a mechanical unit that introduces 100 percent outside air into classrooms and lecture halls. Return air from these areas is reconditioned through the mechanical system and then ducted to the laboratories as supply air. The supply air to the laboratories is exhausted. In this way, the outside air is used twice before being exhausted. Note that this strategy may reduce the ability to transform classrooms into lab spaces in the future.

Numerous strategies can be employed for improving the energy efficiency of cooling, heating, and plumbing systems:

-

Insulate hot water, steam, and chilled water piping.

-

Maintain condenser water as cool as possible, but not less than 20 degrees above chilled water supply temperature.

-

Reuse wasted heat with a heat recovery system.

-

Install an economizer at the boiler. (The water-side economizer will help with humidity controls.)

-

Maintain hot water for washing hands at 105 degrees F. Consider using local hot water tanks at kitchens, restrooms, and other areas instead of central hot water.

-

For plumbing systems, consider using ultra-low-flow toilets (0.5 gallons per flush), waterless urinals, dual flush toilets, ultra-low-flow lavatory faucets, and automated controls such as infrared sensors for faucets.

-

Harvesting rainwater and reusing "gray water" from sinks for irrigation may help reduce water costs.

See also WBDG—High Performance HVAC.

Sustainable Lighting Design

Sustainable lighting design reduces energy use while enhancing employee comfort and productivity. Sustainable lighting strategies include the use of compact fluorescents (CFLs) rather than incandescent lamps, maximizing natural daylighting throughout a facility, and employing various photosensing technologies to conserve energy.

Incandescent lamps are extremely inefficient, energy-wise, using only 10 percent of the energy they consume to produce light (the rest is given off as heat). CFLs should be used instead. Research office lighting can be less than 0.75 watts/sf. connected load, and with lighting controls it may consume less than 0.5 watts/sf. Where functional requirements permit, lighting design should combine task and ambient lighting to reduce the high overall light levels. Good task lighting lessens glare and eyestrain. See also WBDG Energy Efficient Lighting.

LED lighting works extremely well for task lighting. See images below of a flexible and energy efficient task light. Overhead task light with LEDs should be to market by 2015. Now it is widely accepted to have 50 foot candles for ambient lighting.

There are a wide range of shapes and options for lighting and when done well are nice design amenities as shown here at OMRF.

Daylighting

Maximizing the availability of natural daylight is an important principle of sustainable design. Not only does it reduce energy use, but it also increases comfort and enhances productivity. Designers should strive to direct natural light into most laboratory spaces and public areas so that, from almost anywhere in the building, people have the opportunity to look outdoors to see what the weather is like and orient themselves to the time of day. Wherever possible, daylighting should be the primary source of illumination; artificial lighting should be thought of as a supplement to, rather than a replacement for, daylighting.

Typically, the first 15 feet of depth at the perimeter of the building can be entirely lit by daylight during the daytime. The use of light shelves can extend the daylight zone as far as 45 feet into the building. Clerestory windows and skylights can be used to get even more natural daylight into the building. See also WBDG Daylighting.

Daylighting control systems determine the amount of light available in a given space and switch off one or more banks of lights whenever there is enough sunlight. Both full-range and step fluorescent dimming systems work well.

Lighting Controls

A key principle to remember in regard to lighting control systems is "simpler is better." Some systems employ photosensing technologies. Photosensing devices can control off-on for exterior lights, triggering fixtures to add light to a particular area when light levels decline. Also, a number of new fluorescent and metal halide fixtures are available that employ daylight harvesting—storing solar energy in the fixture during daylight hours and then using that energy to run the lamp when daylight diminishes; outdoor lighting systems can easily be retrofitted for these fixtures.

Other photosensing technologies include programmable low-voltage control systems and occupancy sensors. The programmable low-voltage systems can control individual areas of the building or an entire building with one switch. These systems interface with the building automation and dimming systems. They are flexible, can easily accommodate building changes, have a local override capability, and can be used for large or small systems.

Occupancy sensors typically have a one-to-two-year payback. The sensors are designed with adjustable sensitivity levels and timing. There are two technologies: passive infrared and ultrasonic. Passive infrared sensors detect movement of heat between zones. They must have "a line of sight" to detect people in the lab. Ultrasonic occupancy sensors work by broadcasting ultrasonic sound waves, analyzing the returning waves and detecting movement through Doppler shifts. They are effective for larger rooms and can cover a 360-degree area. One problem is that air turbulence can trigger their operation. All occupancy sensor systems must be designed correctly to avoid nuisance operation. See also WBDG Electric Lighting Controls.

C. Other Sustainability Issues

"Green" Products

Some casework products now being manufactured are considered "green." Examples include hardwood, veneer, and plywood products that originate from certified sustainable forests. Steel products can also be "green"—for example, steel laboratory casework and fume hoods made of sheet metal that contains 20 to 25 percent scrap steel. (Sixty percent of the scrap steel comes from old cars and appliances, the other 40 percent from manufacturing fall-off.) There is one problem with recycled steel's "greenness," however: recycling steel is highly energy-intensive, which raises the question whether energy conservation or resource conservation is the better environmental/sustainable strategy. See also WBDG Sustainable—Optimize Building Space and Material Use and Using LEED on Laboratory Projects.

Other Issues

Other sustainable design issues include direct digital control energy management systems, and commissioning the entire building to ensure that building systems are operating as efficiently as possible.

Buildings should be designed with long-term flexibility options, such as the lab module for all architectural and engineering systems, easy connects and disconnects to the engineering systems, and flexible casework. Computers that turn themselves off during non-working hours reduce energy use and cost by reducing cooling loads and electrical demands. Laptop computers use one-tenth the energy of desktop PCs.

Clients are pushing project design teams to create research laboratories that are responsive to current and future needs; that encourage interaction among scientists from various disciplines; that help recruit and retain qualified scientists; and that facilitates partnerships and development. As such, a separate WBDG Resource Page on Trends in Lab Design has been developed to elaborate on this emerging model of laboratory design.

D. Conclusion

All the architectural, engineering, and other sustainability issues should be studied on a project-by-project basis. Factors such as the client's specific goals, the type of lab being designed, the part of the country where the lab is located, and its position on the site will lead to different solutions. See also "Whole Buildings" Design Approach.

The U.S. Environmental Protection Agency (EPA) and the U.S. Department of Energy (DOE) have launched a new, voluntary program to improve the environmental performance of U.S. laboratories called the Laboratories for the 21st Century (Labs21) initiative. Labs21 is designed to improve laboratory energy and water efficiency, encourage the use of renewable energy sources, and promote environmental stewardship. Also available is the Labs21 Environmental Performance Criteria (EPC), a rating system specifically designed to assess the environmental performance of research facilities.

Application

Representative Examples

Numerous facilities have implemented high-performance design features into new or retrofit laboratory projects. Labs21 has developed the following case studies:

- Fred Hutchinson Cancer Research Center

- Lawrence Berkeley National Laboratory In-House Energy Management Program

- National Institutes of Health (NIH) Louis Stokes Laboratories-Building 50

- Nidus Center for Scientific Enterprise, St. Louis, MO

- Pharmacia Corporation Pharmacia Building Q

- Sandia National Laboratories Process and Environmental Technology Laboratory (PETL)

- State of Georgia, Dept. of Public Health Georgia Public Health Laboratory

- U.S. Environmental Protection Agency, National Vehicle and Fuel Emissions Laboratory

Relevant Codes and Standards

Federal Mandates

- Energy Policy Act of 2005

- Executive Order 13693, "Planning for Federal Sustainability in the Next Decade"

The following agencies and organizations have developed codes and standards affecting the design of research laboratories. Note that the codes and standards are minimum requirements. Architects, engineers, and consultants should consider exceeding the applicable requirements whenever possible.

- Code of Federal Regulations, 29 C.F.R. § 1910.1000 "Air Contaminants" (OSHA)

- Code of Federal Regulations, 29 C.F.R. § 1910.1450 "Occupational Exposure to Hazardous Chemicals in Laboratories" (OSHA)

- ANSI/AIHA/ASSE Z9.5 Laboratory Ventilation

- ANSI/ISEA Z358.1 Emergency Eyewash and Shower Equipment

- Association for Assessment and Accreditation of Laboratory Animal Care (AAALAC) Standards

- Biosafety in Microbiological and Biomedical Laboratories, 5th Edition—Department of Health and Human Services, Centers for Disease Control and Prevention and National Institutes of Health

- Guidelines for the Laboratory Use of Chemical Carcinogens, Pub. No. 81-2385—National Institutes of Health

- NIH Design Policy and Guidelines—National Institutes of Health

- NFPA 30 Flammable and Combustible Liquids Code

- NFPA 45 Standard on Fire Protection for Laboratories using Chemical

- PBS-P100 Facilities Standards for the Public Buildings Service—General Services Administration (GSA)

- Unified Facilities Guide Specifications (UFGS)—Tri-Services, organized by MasterFormat™ divisions, are for use in specifying construction for the military services. Several UFGS exist for safety-related topics.

Additional Resources

Federal Requirements

EPA first developed a green buildings vision and policy statement in 1995 and since then the Agency has endeavored to continue leading by example. The following federal statuses require EPA to build, renovate, operate, maintain, and use green buildings:

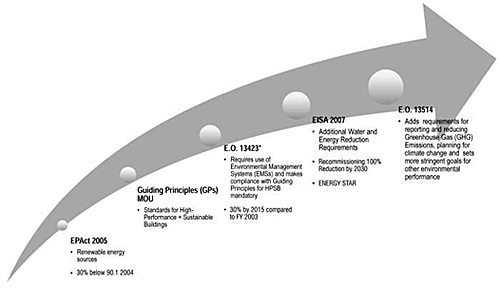

- Energy Policy Act of 2005 (EPAct 2005)

- The Guiding Principles for Federal Leadership in High Performance and Sustainable Buildings (Guiding Principles)

- Executive Order (EO) 13693, "Planning for Federal Sustainability in the Next Decade"

- Energy Independence and Security Act of 2007 (EISA)

- Executive Order (EO) 13514

Energy Policy Act of 2005 (EPAct 2005)

EPAct 2005 requires federal buildings to be designed to achieve energy consumption levels that are at least 30 percent below the American Society of Heating, Air Conditioning, and Engineering (ASHRAE) 90.1-2004 standard, and to apply sustainable design principles to the siting, design, and construction of all new replacement buildings.

The Guiding Principles for Federal Leadership in High Performance and Sustainable Buildings (Guiding Principles)

EPA signed the Federal Leadership in High Performance and Sustainable Buildings Memorandum of Understanding (MOU), along with 21 other agencies, which voluntarily committed the Agency to follow the Guiding Principles. The Guiding Principles, last revised in December 2008, focus on the following five topic areas for both new construction and major renovations:

- Employ integrated design principles (new construction)/Employ integrated assessment, operation, and management principles (existing buildings)

- Optimize energy performance

- Protect and conserve water

- Enhance indoor environmental quality

- Reduce environmental impact of materials

Executive Order (EO) 13423

EO 13423, "Strengthening Federal Environmental, Energy, and Transportation Management," was the first executive order to require federal agencies to implement the Guiding Principles in all new construction and major renovation projects and in at least 15 percent of their existing building inventory (by number of buildings) by the end of FY 2015. In addition, it requires agencies to reduce energy intensity by 3 percent per year, or 30 percent by FY 2015 (compared to an FY 2003 baseline).

Energy Independence and Security Act of 2007 (EISA)

EISA reinforces the energy reduction goals for federal agencies put forth in EO 13423 and introduces a set of more aggressive sustainability requirements. EISA Section 432 requires agencies to complete comprehensive energy and water evaluations at 25 percent of the agency's "covered facilities"—major agency facilities that comprise at least 75 percent of the agency's facility energy use—annually. EISA encourages agencies to implement and verify energy and water efficiency measures identified by these evaluations, and requires that very four years agencies return to conduct recommissioning and look for new energy-saving opportunities.

EISA also requires new or renovated agency building designs to reduce fossil fuel-generated energy consumption compared to an FY 2003 baseline. The required reduction increases such that designs for new buildings or major renovations begun in FY 2030 must reduce fossil fuel-generated energy consumption by 100 percent, equivalent to using zero net energy, compared to an FY 2003 baseline. Starting in 2010, federal agencies are also required to lease space that has earned the ENERGY STAR label in the most recent year.

Executive Order (EO) 13514

EO 13514, "Federal Leadership in Environmental, Energy, and Economic Performance," requires that starting in fiscal year (FY) 2020 federal buildings be designed to achieve "zero net energy" by FY 2030. It reiterates EO 13423's requirement that new construction and major renovations meet the Guiding Principles, and that 15 percent of an agency's existing buildings and leases meet the Guiding Principles by FY 2015. EO 13514 requires agencies to reduce energy, water, and material use through cost-effective strategies and operations and maintenance (O&M) procedures, and to make annual progress toward 100 percent conformance with the Guiding Principles for their building inventories.

Publications

- Building Type Basics for Research Laboratories, 2nd Edition by Daniel Watch. New York, NY: John Wiley & Sons, Inc., 2008.

- Laboratory Design, Construction, and Renovation: Participants, Process, and Product by National Research Council, Committee on Design, Construction, and Renovation of Laboratory Facilities. Washington, DC: National Academy Press, 2000.

Organizations

Others

- Federal Energy Management Program (FEMP), DOE

- Laboratories for the 21st Century (Labs21 Video)—Sponsored by the U.S. Environmental Protection Agency and the U.S. Department of Energy, Labs21 is a voluntary program dedicated to improving the environmental performance of U.S. laboratories.

- Labs21 Tool Kit

- A Design Guide for Energy-Efficient Research Laboratories—A reference that helps facility owners, managers, and designers and apply energy-efficiency features in laboratories.

- Environmental Performance Criteria—A rating system specifically designed to assess environmental performance of laboratories.