by Joseph C. Dean, P.E., Steve Geusic, P.E., and Terri M. Regin, P.E., for Corrosion Policy & Oversight (DASD) [Materiel Readiness]

Updated: 12-03-2021

Introduction

Within This Page

Although, the word "corrosion" is most often associated with "rust" and the oxidation of other metals, 10 U.S.C. § 2228 defines corrosion as, "the deterioration of a material or its properties due to a reaction of that material with its chemical environment." It is inclusive of the deterioration of all materials, which can be caused through sun exposure, moisture (mold and mildew), wind, and other environmental factors.

Facilities affected by corrosion include, but are not limited to petroleum tanks (above and underground ground storage tanks (AST) and (UST)), POL pipelines, and associated structures such as valves, pumps, and fasteners. Corrosion of POL pipelines and storage tanks can occur on the exterior due to atmospheric effects and soil corrosivity as well as internal corrosion. As a result, corrosion effects often remain unseen or unnoticed until they are inspected by various non-destructive examination methods or in a failure mode. Understanding Corrosion Science as it affects POL pipelines, storage tanks and associated structures will help the designer and Sustainment, Restoration and Modernization (SRM) manager make decisions that create facilities that are life cycle cost effective, more durable and operationally responsive.

Description

Perhaps one of the most important aspects of fuels facilities management is understanding the roles, responsibilities, funding sources, and authorities related to every location and type of system (e.g. pipeline, valves, tankage, pantographs, cathodic protection (CP) system, etc.). Planning and executing an effective fuels facilities corrosion prevention and control (CPC) program will help to effectively maintain the facilities and ensure mission support. This Knowledge Page includes CPC insights and information related to POL Storage and Distribution systems. It does not address issues related to the division of responsibility between the Defense Logistics Agency and the Military Services. For specific guidance on that topic see DoDM 4140.25 , Volume 8, DoD Management of Energy Commodities: Energy Commodity Infrastructure Operations. Funding for the sustainment, restoration, and maintenance (SRM) of POL Storage and Distribution systems often competes with other requirements. Leveraging funds from multiple sources such as DLA helps to address overall deficiencies. However, non-DLA capitalized facilities such as generator tanks and pipelines may result in unchecked corrosion deterioration, which increases the risk of fuel leaks, tank failures and disruptions to operations. See DoDM 4140.25, Service level instructions, and WBDG resources for more insights into how to manage these issues.

The reliability of POL Storage and Distribution systems has a huge impact on our daily lives and mission effectiveness. System integrity is a function of good design decisions and sustainment activities for the storage and distribution of liquid fuels that support aircraft, ships, and ground vehicles. Sustainment actions include tank and piping inspections, CP testing, maintenance and repairs. In areas of high chloride environments, such as marine locations, the effects of corrosion on carbon steel POL systems are more aggressive. Coating failures will lead to small areas of corrosion and will tend to increase over time. Installations in these locations spend considerable amount of resources addressing the corrosion in order to reduce the rate of corrosion damage. See the Environmental Severity Classification (ESC) web page and the Corrosion Toolbox to assist in identifying the correct CPC approach.

The WBDG includes an extensive library of Unified Facilities Criteria (UFC) and Unified Facilities Guide Specifications (UFGS) that incorporate material selection, coatings, CP, and a combination of CPC-related factors that must be considered in the design and maintenance of these facilities to lower the life-cycle costs attributable to corrosion. The designer and sustainment professional must understand and leverage this guidance. As in most criteria documents, best practice and mandatory design, construction and sustainment requirements are described. Because the risks are so high with POL storage and distribution systems, these criteria documents must be carefully leveraged to ensure good life cycle and operational results.

Photo 1: Corrosion at a Valve Cover (Guam) and

Source: FICE Study 2013

Photo 2: Example of Aboveground Support Corrosion

Source: FICE Study 2013

Design and Durability Issues

In paragraph 3-5, Specification Requirements, UFC 1-200-01 DoD Building Code (General Building Requirements), requires the use of UFGS in accordance with UFC 1-300-02 UFGS Format Standard Content Guidance. The UFC 1-200-01 requires that designers "provide bracketed or tailored options, and Notes to the Designer, in the UFGS sections when the selection of a material, component, or system for corrosion prevention, life cycle cost effectiveness, or durability depends on the location, application, conditions, or atmospheric and chemical environment. In the notes, provide direction on identifying and selecting those variables." UFC 1-300-02 also states that "ISO [International Organization for Standardization] 9223 and Environmental Severity Classification (ESC) factors, [should be used] to help specify when to use materials, coatings, and other design elements in a given project location or atmospheric environment. Additionally, provide direction on what item to use based on other relative criteria such as soil corrosivity, ultraviolet exposure, solar radiation, biological, or other factors causing deterioration of a material or its properties because of a reaction of that material with its chemical environment." Ideally, all components of POL storage and distribution systems should address corrosion vulnerability and durability.

ESC is explained in the CPC Source ESC Web Page and can be calculated for the specific location under consideration in the ISO Corrosivity Category Estimation Tool (ICCET) Toolbox. The Appendix D Table is also provided for a quick view of specific installation ESC Zone calculations, although the designer should utilize the ICCET Tool for the most accurate "C" classification. If the ESC zone lies between C3 and C5 an added level of corrosion protection is required to ensure a more durable life cycle cost effective facility. This includes the selection of more corrosion resistant coatings, material selection, and design details consistent with that ESC Zone.

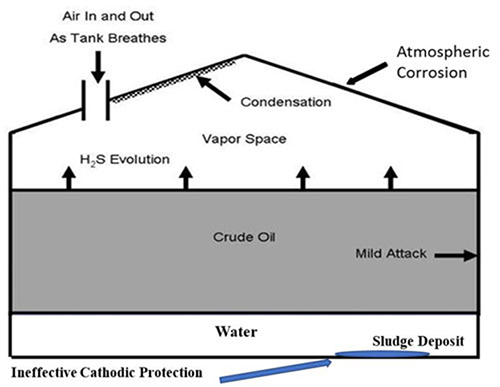

Corrosion of POL facilities can occur on the exterior due to atmospheric effects and submerged conditions such as soil corrosivity. External corrosion such as pitting and surface erosion can occur due to the external environment. Internal corrosion can occur as a result of a variety of sources including condensation, hydrogen sulfide (H2S) evolution, the water dropping out of the fuel and sitting on the tank bottom for a long duration, and biological activity. Fuels such as biodiesel, low-sulfur diesel, and fuel containing high levels of ethanol can be corrosive.

Figure 1: Fuel Storage Tank — Combined Corrosion Effects

Source: Steve Geusic, P.E.

Corrosion can degrade components such as pipes, conduits, valves, fasteners, and tanks. Identifying the corrosive forces and employment of POL CPC design, construction, and sustainment strategies include:

- Identification of the appropriate, ESC Zone for above ground structures

- Identification of the corrosivity of the environment existing in soils:

- Resistivity

- Moisture

- Acidity

- Chlorides, sulfides, and bacteria

- Differences in soil composition

- Stray currents

- Identification of the internal environment and chemistry of tanks, pipes and conduits, valves, and pumps

- Vented environment

- Fuel type, properties, and additives

- Filtration and prevention/removal of contaminants and sludge/sediment

- Sulfur content — The reduction in sulfur content results in a reduction in overall lubricity and conductivity of the fuel. A lower lubricity level can cause premature wear, damage, and corrosion to metal parts

- Selection of appropriate materials including compatibility with the fuel product

- Prevention of dissimilar metal corrosion

- Ensuring that good and durable design geometrics are included in the completed or repaired facility

- Grounding and bonding locations and details

- Use of protective coatings, linings, isolators, and corrosion inhibitors

- Visual and non-destructive examination of the POL Storage and Distribution systems in accordance with recognized standards

- Operation and inspection/maintenance of leak detection systems

- Consideration of alternate materials for components proximate to salt water and in areas of high environmental severity. Select appropriate materials and coatings for vaults and pits, and consider isolation at conduit penetrations

- Prevention of entrapment of water and moisture intrusion

- Consultation with subject matter experts and stakeholders when appropriate

- Providing close attention to construction practices that can increase corrosion risks:

- Field modifications and material substitutions

- Improper storage of materials

- Damage to coatings

- Field cuts and cut edge corrosion

- Elimination of crevices

- Reduction of rough and sharp surfaces

- Ensuring appropriate coating selection, surface preparation, and application

- Improper welding

- Improper selection of fasteners and lack of corrosion protection for fasteners after installation. Note that fasteners are always problematic; it may be caused by the fastener itself, or it could be caused by the area around the fastener where coatings have been damaged or where galvanic corrosion occurs

- Improper installation of gaskets and other features that would allow leakage and infiltration into the structure (e.g. pipeline, valves, access manhole, CP feature, etc.)

- Note: UFC 3-190-06 Protective Coatings and Paints and various UFGS provide detailed information on coating requirements and guidance for various components and systems (see the Additional Resources section at the end of this Knowledge Page for additional insights and resources).

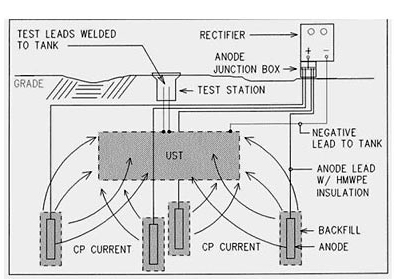

Cathodic Protection (CP)

UFC 3-460-01 Design: Petroleum Fuel Facilities requires CP for underground steel tanks and tank bottoms of aboveground vertical tanks. CP is also required for all carbon steel and stainless steel underground and underwater piping associated with underground storage tanks. Properly installed and maintained CP systems can reduce life cycle costs by indefinitely extending a utility's lifecycle. These systems can also reduce the potential liability from premature failure of utilities, such as jet fuel leaks, while also ensuring the avoidance costs associated with the leaks such as fines, environmental cleanup, remediation and disposal of contaminated soil, and monitoring requirements. UFC 3-570-01, Cathodic Protection states that "Petroleum, oil and lubricant (POL) systems, waterfront structures, and utility systems have been found to be the most critical facilities in terms of a combination of risk from corrosion, the need for continuous direct support of base operations, and the life cycle cost effectiveness of utilizing appropriate corrosion control systems." It also states that CP is mandatory "regardless of soil or water corrosiveness" and CP systems and protective coatings must be provided for buried or submerged metallic structures to include "Petroleum, Oil, and Lubricants (POL) pipelines" and "Underground POL/gas storage tanks, piping, and ancillary items." CP systems are not useful for structures that are not buried or submerged.

Coatings and CP should most always be used in conjunction with each other as required to safely sustain POL distribution and storage. Both are required by law for USTs and certain POL lines. For additional information on CP see Continuing Education DoD Courses (login account required) and Cathodic Protection Knowledge Area. See also CP assessment, design, installation and sustainment (see UFC 3-570-01 Cathodic Protection and UFC 3-570-06 Operation and Maintenance: Cathodic Protection Systems).

Photo 3: Cathodic Protection System (Quantico MB)

Source: FICE Study (2013)

Photo 4: Impressed Current Cathodic Protection System for Underground Storage Tank

Source: FICE Study (2013)

Common systems and structures requiring protective coatings and CP regardless of soil or water corrosivity include:

- POL pipelines — aboveground and underground

- POL system components — valves, nuts & bolts, meters, pumps, etc.

- Underground and above ground storage tanks (UST and AST)

For POL distribution pipelines the key parameters affecting internal pipe corrosion are:

- Percentage of water in fuels and composition (pH, Alkalinity, Dissolved Oxygen)

- Ferric scale

- Flow conditions

- Biological activity

- Disinfectants

- Corrosion inhibitors

Photo 5: Guam POL Pipelines

Source: FICE Study (2013)

Facility SRM managers need to maintain in—house CP expertise to perform the day to day routine maintenance and inspection. DLA funds annual inspection and testing of CP systems associated with DLA—capitalized POL facilities. CP is a specialized area of electrical technology so in-house electrical technicians need to be provided the resources to obtain and maintain their knowledge in CP. The insights provided in the Corrosion Prevention and Control Checklists Tool can be leveraged to provide durable and well-maintained CP systems.

Criteria and Standard Design Highlights

While not a complete list, some specific UFC and UFGS highlights follow. For a complete list of resources see the "Additional Resources" Section at the end of this page. In addition to the UFC and UFGS listed, there are several DoD standard designs (Non-COS Standards) that have been developed for POL facilities. A description of these standard designs follow at the end of this section.

-

UFC 3-190-06 Protective Coatings and Paints provides requirements and technical guidance for the effective use of paint-type coatings to protect common materials such as metal, concrete, pavements, gypsum board and wooden structures at military activities from deterioration. This UFC applies to all Navy, Air Force, and Army service elements and contractors. Requires paints and coatings that are durable and minimize the need for preventative and corrective maintenance over the expected service life of the component or system. Note that this is a significant update from previous versions. Different materials will be used based on local environmental conditions (See UFC 1-200-01 as required in the UFC). Corrosive environments, which require additional corrosion protection, are those project locations which have an Environmental Severity Classification (ESC) of C3, C4 or C5. Humid locations are those in ASHRAE climate zones 0A, 1A, 2A, 3A, 3C, 4C, and 5C (as identified in ASHRAE 90.1). Defines coating systems for specific uses.

-

UFC 3-460-01 Design: Petroleum Fuel Facilities addresses corrosion design issues to include impacts of ethanol, hazards related to corrosion, certification issues and tank size, CP for above and underground tanks, pipelines and structures, corrosion on underground submerged piping systems, and corrosion resources, guidance and references. Soils shall have a minimum electrical resistance of 35,000 ohm-cm. Foundation material should be neutral or alkaline with a pH greater than 7, a chloride concentration less than 300 ppm, and a sulfate concentration less than 150 ppm as specified by DoD Standard Design AW 78-24-27. The UFC 3-460-01 requires the services of a (NACE)-certified Corrosion Specialist, Cathodic Protection Specialist or a registered professional Corrosion Engineer to perform all CP design and testing.

-

UFC 3-460-03 O&M: Maintenance of Petroleum Systems provides guidance on corrosion-related inspections for specific system locations, pitting corrosion impacts, and CP systems.

-

UFC 3-501-01 Electrical Engineering provides the governing criteria for electrical systems, explains the delineation between the different electrical-related UFCs, and refers to UFC 3-570-01 for CP requirements. UFC 3-501-01 should be used for design analysis, calculation, and drawing requirements.

-

UFC 3-570-01 Cathodic Protection provides policy and design requirements for CP systems which include fuels-related applications and associated qualification requirements for professionals providing design and engineering advice. The UFC provides the minimum design requirements, and must be utilized in the development of plans, specifications, calculations, and Design/Build Request for Proposals (RFP).

-

UFC 3-570-06 O&M: Cathodic Protections Systems provides guidance for inspection, operation, and maintenance of CP systems and should be used by field personnel to perform scheduled inspections and preventive maintenance, and to troubleshoot and repair defects.

-

UFGS 02 65 00 Underground Storage Tank Removal addresses removal and disposal of underground, non-hardened tanks and piping used to store petroleum products, waste oils or hazardous wastes in accordance with Federal, State, and local regulations. EPA requirements are addressed.

-

UFGS 09 90 00 Paints and Coatings addresses "requirements for painting of new and existing, interior and exterior substrates." Discusses corrosion and invokes UFC 1-200-01. Delineates ESC requirements for ESC Zones C3, C4 and C5 and ASHRAE 90.1 humid locations in climate zones )A, 1A, 2A, 3A, 4C and 5C. It includes contractor qualification requirements (SSPC QP 1, QP 2, etc.) and refers to SSPC, NACE, and MPI Standards. Topics include coatings, corrosion, rust, deterioration, mold, and mildew.

-

UFGS 09 97 13.15 Low Voc Polysulfide Interior Coating Of Welded Steel Petroleum Fuel Tanks> < 50 grams/liter) two-coat polysulfide modified novolac epoxy [PMNE] coating [system] for interiors of newly constructed, Navy bulk fuel storage tanks." Notes in the UFGS discuss maintenance coating design. Contractor qualifications and experience (SSPC QP 5, MPCAC-C14) are delineated. Discusses corrosion limitations. While it does not directly address ESC requirements, it does invoke UFC 1-300-02 which does.

-

UFGS 09 97 13.17 Three Coat Epoxy Interior Coating of Welded Steel Petroleum Fuel Tanks "covers the requirements for a three coat epoxy system for interior coating of newly constructed bulk fuel storage tanks." This coating system is not as robust as the Low VOC Poloysulfide coating system, it has a much lower life expectancy, and its life cycle cost is higher for tanks with a longer than a 40 year life expectancy.

-

UFGS 09 97 13.27 High Performance Coating For Steel Structures "covers the requirements for using zinc-rich epoxy/epoxy/polyurethane coating systems for exteriors of new Navy and Air Force steel structures, such as fuel tanks, water tanks, [and] aboveground piping." Extensive notes at the beginning of the UFGS describe special requirements and recommendations. Contractor qualifications and certifications include SSPC PCS and SSPC QP 5. Invokes UFC 1-300-02. Designers are encouraged to contact the AFCEC Corrosion Engineer and NAVFAC Atlantic with questions and clarification of the UFGS guidance.

-

UFGS 09 97 13.28 Protection of Buried Steel Piping and Steel Bulkhead Tie Rods "covers the requirements and application methods for tape wrapping systems that establish exterior protection of buried steel piping and steel bulkhead tie rods that rest above the reference level, 600 mm [2 feet] below Mean Low Water [MLW] or Mean Lower Low Water [MLLW], and for tape coating of buried steel pipe covered with an adhesive thermoplastic resin coating system, a thermosetting epoxy coating system, or a polyethylene-butyl adhesive system" (p. 3). The UFGS states, inspection shall be performed by a [NACE-]certified inspector. Corrosion is mentioned. Invokes UFC 1-300-02. Use only epoxy coatings where petroleum fuels are expected.

-

"UFGS 33 01 50.65 Inspection of Field Fabricated Fuel Storage Tanks covers the requirements for performing Coating Condition Surveys (CCS) during the inspection of Fuel Storage Tanks. The CCS is to be perform by an independent NACE Certified Protective Coating Specialist (PCS).

-

UFGS 33 08 55 Fuel Distribution System Start-Up (Non-Hydrant) discusses submittal requirements and testing of coating applications prior to fuel delivery (e.g., as-built drawings, equipment warranty documentation, etc.)

-

UFGS 33 52 10 Fuel System Piping (Service Station) and UFGS 33 52 40 Fuel Systems Piping (Non-Hydrant) and UFGS 33 52 43.13 Aviation Fuel Piping provides extensive guidance on CP control systems, flange protectors and pressure relief valve corrosion protection.

-

UFGS 33 52 43.11 Aviation Fuel Mechanical Equipment provides extensive guidance for equipment component corrosion resistant decisions.

-

UFGS 33 52 80 Liquid Fuels Pipeline Coating Systems covers the requirements for interior and exterior coating of aboveground and buried, carbon steel, liquid fuel pipelines.

-

UFGS 33 56 10 Factory-Fabricated Fuel Storage Tanks describes CP, corrosion protection systems and installation procedures to resist corrosion impacts.

-

UFGS 33 56 21.17 Single Wall Aboveground Fixed Roof Steel POL Storage Tank covers the required for interior and exterior coating of fuel storage tanks.

-

UFGS 33 56 21.18 Single Wall POL Tank Undertank Interstitial Space describes CP requirements for protecting the soil-side of the tank bottom.

-

AW 078-24-27 DOD Aboveground Vertical Steel Fuel Tanks with Fixed Roofs provides the standard design for different sizes of aboveground fuel storage tanks. This design includes the components and the materials that are to be incorporated into the tank design. This design also includes recommendations for the Cathodic Protection and leak detection.

-

AW 078-24-28 DOD Pressurized Hydrant Fueling System Type III provides the layout of the piping and equipment for a Type III system.

-

AW 078-24-29 DOD Standard Pressurized Hydrant Direct Fueling System Type IV/V provides the layout of the piping and equipment for a Type IV/V system.

-

AW 078-24-33 DOD Cut and Cover Standards provides the standard design for different sizes of field constructed underground fuel storage tanks. This design includes the components and the materials that are to be incorporated into the tank design. This design also includes recommendations for the Cathodic Protection and leak detection.

-

Fuel Pier—NAVFAC Drawings 10009724 Through 10009734 provides the layout of the piping and equipment for a fueling system on a Pier.

-

STD 121-122-01 USAFE/NATO, Airfield Standard Design US, Jet Fuel Storage Dispensing Systems For Tactical And Wide Body Aircraft provides the layout of the piping and equipment for the USAFE/NATO fueling system on Airfields. This standard design also includes the cut-and-cover tank design and associated components.

-

STD 123-335-03 DOD Military Service Station and Factory Fabricated Tank Engineering Standard provides the layout of the piping and equipment for Military Service stations (non-POV), including the above- and under- ground tanks, truck off-load, and dispensing stations.

It is recommended that the designer carefully review each criteria document to ensure that the appropriate materials are selected and placed in service along with the associated processes. Submittals may include shop drawings, product data, samples, test reports, certificates, manufacturer's instructions, and operation and maintenance data.

Petroleum Storage Inspections

There is an inherent environmental risk where POL storage tanks and distribution systems are concerned. A system failure may result in a release to the surrounding areas and an interruption to the mission of the activity and the weapons systems that it supports. Fuel spills, mechanical failures, tank leaks, all result in an interruption of service if not addressed immediately. Conducting an aggressive preventive maintenance program (see UFC 3-460-03 O&M: Maintenance of Petroleum Systems) along with required regulatory compliance inspections, such as API Standard 653, STI SP001, and API 570, will contribute to risk reduction. The POL fuel storage tanks are to be inspected in accordance with UFGS 33 01 50.65. During these inspections attention to CPC throughout the life cycle will significantly further reduce the risks.

Photo 6: Vertical Upright Aboveground Storage Fuel Tank (JBER)

Source: FICE Study (2013)

Photo 7: Cut and Cover Underground Storage Tank (Guam)

Source: FICE Study (2013)

Photo 8: Shop Fabricated Aboveground Storage Tanks (Quantico MCB)

Source: FICE Study (2013)

Photo 9: Shop Fabricated Aboveground Storage Tanks and Piping (Guam)

Source: FICE Study (2013)

Several sources provide meaningful insights into petroleum storage issues. For example:

- UFC 3-460-03 O&M: Maintenance of Petroleum Systems provides the following corrosion related insights:

-

"Inactive systems may accumulate water at low points and cause corrosion or biological activity leading to solids contamination."

-

"Microbiological contamination usually appears as a brown, black, or gray slime-like deposit that adheres to the inner surface of fuel tanks. This results in corrosion of fuel system components also known as Microbial Influenced Corrosion (MIC), clogging of filters and erratic operation or petroleum fuel quality indicating systems. …and can cause significant damage to tanks and piping and environmental problems in very short periods of time." CP does not seem to mitigate microbial influenced contamination for diesel storage tanks.

-

- EPA provides the following insights on corrosion and USTs in the storage of diesel fuel.

-

Storing a fuel that is not compatible with an UST system may jeopardize the integrity of the UST system and cause a release to the environment.

-

The corrosion may cause metal components inside both steel and fiberglass UST systems to corrode. This can possibly shorten the lifespan or affect the serviceability of components, including limiting the movement of floats on automatic tank gauging systems, operability of mechanical devices designed to prevent the chance of overfilling the tank, or ability of shear valves to shut off flow of product in the event of a release.

-

Corrosion may cause dispenser filters to clog and be replaced more frequently and could potentially limit the proper functionality of equipment designed to test for leaks in fuel product lines.

-

EPA recommends UST owners check for corrosion in their tank systems storing diesel fuel, and if they find corrosion, repair or replace equipment as necessary to ensure proper functionality."

-

- See also "Data About The Underground Storage Tank (UST) Program" for additional UST insights.

Lessons Learned and Input From the Field

-

Consistent with DoD Directive 4270.5 (Military Construction) , utilize the CPC criteria and information hosted on the Whole Building Design Guide including UFC, UFGS, Standard Designs, Engineering and Construction Bulletins (ECB), and performance technical specifications. If necessary, mark—up guide specifications (e.g., UFGS) with prescriptive CPC requirements.

-

Replace older USTs with ASTs or with double-walled USTs that have an upgraded CP system or are constructed with fiberglass, and have an interstitial space for leak monitoring.

-

Use aggressive preventative maintenance programs to ensure that there is early detection of deficiencies and reduction of deterioration due to coating failure and/or corrosion.

-

Coordinate utility work with utility owners.

-

Ensure that corrosion prevention is discussed at the design/construction kick-off meeting and implemented on the plans at each submittal stage.

-

Ensure that POL storage and distribution systems as-built drawings are included in the e-OMSI package [UFGS 01 78 24.00 20 Facility Electronic Operation and Maintenance Support Information (eOMSI)] at facility turnover from the Construction Agent.

-

Review and coordinate projects by a committee of public works design and maintenance, safety, environmental, and security to ensure projects are fully coordinated before work begins. This is especially important when dig permits are required, ensuring that minimal damage to existing buried structures occurs.

-

Ensure that funding is sufficient to include CPC materials and coatings that are life cycle cost effective, appropriate for the environment where the project is located, and that are able to reach the intended service life without extensive preventative or corrective maintenance.

-

Ensure that personnel engaged in CPC decision-making activities, such as acquisition, design, inspection, maintenance, and repair, have appropriate training and qualifications. See UFC 3-460-01 Design: Petroleum Facilities, Cathodic Protection and Structures for examples. See also CPC Competencies, CPC Training, and Facilities Corrosion Knowledge Track Summary for additional insights.

-

Once facilities are in service, control corrosion prevention through proper maintenance practices and adequate sustainment resources.

-

Ensure that the CP systems are maintained and checked based upon recommended cycles.

Summary

A few items to remember and apply are:

- Maintain and conduct an active preventative maintenance program to include inspections that focus on CPC.

- Maintain and inspect CP systems.

- Incorporate good Design Geometrics.

- Awareness and application of ESC Zone.

- Ensure that the design component or assembly complies with the requirements from the RFP, including performance technical specifications, referenced UFC and UFGS documents.

- Ensure that the design drawings and specifications address CPC through proper choice of materials and coatings.

- Select and specify materials and coatings that have low life cycle costs, are durable, and minimize the need for preventative and corrective maintenance. Initial investments in corrosion prevention are typically more life—cycle cost effective than maintenance, repair, and replacement of prematurely degraded components.

- Design and specify POL storage and distribution systems to reach the intended service life, including the use of enhanced materials, coatings, and appropriate application of CP as defined in UFC and UFGS criteria in severe corrosive environments.

- Leverage the insights provided in the Corrosion Prevention and Control Checklists Tool

Additional Resources

Criteria on the WBDG are generally based on industry standards. An industry standard is an established norm or requirement about technical systems, usually presented in the form of a formal document. It establishes uniform engineering or technical criteria, methods, processes and practices. Industry Standards can also be found in the form of reference specifications. The standards referenced in criteria are usually written and maintained by Standards Organizations (see also WBDG Taxonomy). It should be noted that the guidance, references and UFC/UFGS list is extensive. This section is not intended to be complete. It is intended to serve as an assist and a reminder that this area is complex and poses a high risk to individuals, installations and the environment. Appropriate design, construction and SRM actions are absolutely essential. Paying attention to the "small stuff" as well as the "large" will result in a facility that will meet life cycle expectations. See the following for additional guidance and information.

Department of Defense

Unified Facilities Criteria (UFC)

- UFC 1-200-01 DoD Building Code (General Building Requirements)

- UFC 1-300-02 UFGS Format Standard

- UFC 3-190-06 Protective Coatings and Paints

- UFC 3-301-01 Structural Engineering

- UFC 3-420-01 Plumbing Systems

- UFC 3-460-01 Design: Petroleum Fuel Facilities

- UFC 3-460-03 O&M: Maintenance Of Petroleum Systems

- UFC 3-501-01 Electrical Engineering

- UFC 3-570-01 Cathodic Protection

- UFC 3-570-06 O&M: Cathodic Protection Systems

- UFC 3-575-01 Lightning and Static Electricity Protection Systems

- UFC 3-600-01 Fire Protection Engineering for Facilities

- UFC 3-810-01N Navy and Marine Corps Environmental Engineering for Facility Construction

- UFC 4-020-01 DoD Security Engineering Facilities Planning Manual

- UFC 4-141-10N Design: Aviation Operation and Support Facilities

- UFC 4-150-02 Dockside Utilities for Ship Service

Unified Facilities Guide Specifications (UFGS)

- UFGS 01 78 24.00 20 Facility Electronic Operations and Maintenance Support Information (eOMSI)

- UFGS 02 65 00 Underground Storage Tank Removal

- UFGS 09 90 00 Paints and Coatings

- UFGS 09 96 00 High-Performance Coatings

- UFGS 09 97 02 Painting: Hydraulic Structures

- UFGS 09 97 10.00 10 Metallic Coatings for Hydraulic Structures

- UFGS 09 97 13.00 40 Steel Coatings

- UFGS 09 97 13.15 Low VOC Polysulfide Interior Coating of Welded Steel Petroleum Fuel Tanks

- UFGS 09 97 13.17 Three Coat Epoxy Interior Coating of Welded Steel Petroleum Fuel Tanks

- UFGS 09 97 13.27 High Performance Coating for Steel Structures

- UFGS 09 97 13.28 Protection of Buried Steel Piping and Steel Bulkhead Tie Rods

- UFGS 26 42 13 Galvanic (Sacrificial) Anode Cathodic Protection (GACP) System

- UFGS 26 42 17 Impressed Current Cathodic Protection (ICCP) System

- UFGS 33 01 50.55 Cleaning of Petroleum Storage Tanks

- UFGS 33 01 50.65 Inspection of Field Fabricated Fuel Storage Tanks

- UFGS 33 08 53 Aviation Fuel Distribution System Start-Up

- UFGS 33 08 55 Fuel Distribution System Start-Up (Non-Hydrant)

- UFGS 33 11 23 Natural Gas and Liquid Petroleum Piping

- UFGS 33 51 15 Natural-Gas / Liquid Petroleum Gas Distribution Pipelines

- UFGS 33 52 10 Fuel Systems Piping (Service Station)

- UFGS 33 52 40 Fuel System Piping (Non-Hydrant)

- UFGS 33 52 43.11 Aviation Fuel Mechanical Equipment

- UFGS 33 52 43.13 Aviation Fuel Piping

- UFGS 33 52 43.23 Aviation Fuel Pumps

- UFGS 33 52 80 Liquid Fuels Pipeline Coating Systems

- UFGS 33 56 10 Factory-Fabricated Fuel Storage Tanks

- UFGS 33 56 21.17 Single Wall Aboveground Fixed Roof Steel POL Storage Tank

- UFGS 33 56 21.18 Single Wall POL Tank Undertank Interstitial Space

- UFGS 33 61 13.19 Valves, Piping, and Equipment In Valve Manholes

- UFGS 40 05 13 Pipelines, Liquid Process Piping

- UFGS 41 65 10.00 10 [Diesel][Natural Gas] Fueled Engine Pump Drives

DoD Manual

- DoDM 4140.25 , Volume 8, DoD Management of Energy Commodities: Energy Commodity Infrastructure Operations

- DoD 5200.8-R Physical Security Program

AFCEC — Air Force

Navy — NAVFAC

- Marianas Navy and Marine Corps Design and Construction Standards (MDACS), September 2017, Naval Facilities Engineering Command

WBDG

- Federal Facility Criteria—Extensive electronic library of construction guide specifications, manuals, standards and many other essential criteria documents

- Unified Facilities Criteria—Master list of UFCs

- Unified Facilities Guide Specifications—Master list of UFGSs

- Unified Master Reference List (UMRL)—Lists publications/Industry criteria referenced in UFGSs

- CPC Source Criteria

- WBDG Corrosion Prevention and Control Source

- WBDG Corrosion Prevention and Control Source — Cathodic Protection Knowledge Area

- WBDG Corrosion Prevention and Control Source — Utilities and Buried Structures Knowledge Area

- Corrosion Toolbox

- Facilities Environmental Severity Classification Study Report

- Corrosion Factors in DoD Facilities , Vision Point Systems, October 24, 2014

- Architectural Painting Specification Decision Tree

- Corrosion Prevention and Control Checklists Tool

American Society for Testing and Materials (ASTM)

U.S. Army Corps of Engineers — Public Works Technical Bulletin (PWTB)

- Public Works Techincal Bulletin (PWTB) 420-49-36, Leak Detection, USACE, 15 June 2001

Code of Federal Regulations (CFR)

- 40 C.F.R. § 280, "Technical Standards and Corrective Action Requirements for Owners and Operators of Underground Storage Tanks (UST)"

- 49 C.F.R. § 195, "Transportation of Hazardous Liquids by Pipeline"

Environmental Protection Agency Publications / References

- EPA Underground Storage Tank Website

- EPA Website, Emerging Fuels and Underground Storage Tanks (USTs)

- EPA, Notice Of Corrosion Risks In Underground Storage Tanks Storing Diesel Fuel US Environmental Protection Agency, Office Of Underground Storage Tanks, July 2016

- EPA, Operating and Maintaining Underground Storage Tank Systems: Practical Help and Checklists, February 2016

- EPA, Investigation of Corrosion-Influencing Factors in Underground Storage Tanks with Diesel Service, July 2016

- Notice of Corrosion Risks in Underground Storage Tanks Storing Diesel Fuel, U.S. Environmental Protection Agency, Office of Underground Storage Tanks, July 2016

Steel Tank Institute

- Steel Tank Institute Recommended Practice for Storage Tank Maintenance R111 Revision, March 2016

- SP001 Standard for the Inspection of Aboveground Storage Tanks

- SP031 Standard for Repair Shop Fabricated Aboveground Tanks

- SP131 Standard for Inspection and Repair Underground Steel Tanks

Industry Organizations

The following Industry Organizations are identified in the UFCs and UFGSs associated with POL distribution, storage and associated components. The relevant Standards are listed in each criteria document and are too extensive to list here.

- American Institute of Steel Construction (AISC)

- American Iron and Steel Institute (AISI)

- American National Standards Institute (ANSI)

- American Petroleum Institute (API)

- American Society of Civil Engineers (ASCE)

- American Society of Mechanical Engineers (ASME)

- American Society for Nondestructive Testing (ASNT)

- American Society for Testing and Materials (ASTM)

- American Welding Society (AWS)

- Coordinating Research Council

- CSA Group

- Factory Mutual Global Corporation

- International Organization for Standardization

- International Zinc Association

- Institute of Electrical and Electronics Engineers (IEEE)

- National Electrical Manufacturers Association (NEMA)

- National Fire Protection Association (NFPA)

- Underwriters Laboratories (UL)

International Organization for Standardization (ISO)

- ISO 9223:2012 Corrosion of metals and alloys — Corrosivity of atmospheres — Classification, determination and estimation, February 1, 2012

- ISO 9224:2012 Corrosion of metals and alloys — Corrosivity of atmospheres — Guiding values for the corrosivity categories, February 1, 2012

- ISO 9226:2012 Corrosion of metals and alloys — Corrosivity of atmospheres — Determination of corrosion rate of standard specimens for the evaluation of corrosivity, February 1, 2012

AMPP (NACE and SSPC)

- SP0169 Control of External Corrosion on Underground or Submerged Metallic Piping Systems

- SP0193 External Cathodic Protection of On-Grade Carbon Steel Storage Tank Bottoms

- SP0285 Corrosion Control of Underground Storage Tank Systems by Cathodic Protection

- SP0102, In-Line Inspection of Pipelines

- TM0497, Measurement Techniques Related to Criteria for Cathodic Protection on Underground or Submerged Metallic Piping Systems

DoD and WBDG CPC Facilities Training

- CPC Source Training

- Facilities Corrosion Knowledge Track Summary

- Defense Acquisition University

- Environmental Protection Agency UST Inspector Training

- The Army Corps of Engineers Learning Center

- WBDG DoD Courses