by Joseph C. Dean, P.E., Steve Geusic, P.E., M. Thadd Buzan (OASD for Sustainment), and Joseph M. Woliver, P.E., NAVFAC Atlantic, for the Director, Corrosion Policy & Oversight (DCPO), (OASD for Materiel Readiness)

Updated: 09-21-2022

INTRODUCTION

Within This Page

Corrosion impacts on asphalt concrete (AC) and Portland cement concrete (PCC) pavements can be extensive and contribute to costly repairs, replacement and mission degradation. It is especially important to construct and sustain the pavement structures according to the design and associated criteria requirements, thus reducing the risk of corrosion and degradation. One of the biggest differences between AC and PCC is NOT just the design approach that is commonly understood (flexible vs. rigid pavement), but their corrosion failure mode. The nemesis of PCC is water and salt getting to its steel reinforcement. The nemesis of AC is sunlight. This is a major consideration in design options related to local environmental conditions.

Limited resources available for competing (non-pavement) projects often result in the easier, less costly, requirements being addressed, while the pavement repairs get deferred. AC and PCC pavement failures can be both gradual and catastrophic, with the cost to defer essential repairs increasing over time.

Pavements are the essential connector and launching platform for DoD installations, airfields, waterfronts, and to and from adjacent communities. Pavements include both AC and PCC surfaces that are associated with:

- Airfield runways and taxiways

- Airfield parking aprons

- Helipads

- Aircraft wash and rinse areas

- Vehicle wash and rinse areas

- Roads

- Parking areas and lots

- Bridges

- Waterfront

- Piers

- Dry-docks

- Sidewalks

- Walking paths

- Elevated walkways

Operational and mission impacts can include the following:

- Airfield runways, ramps, and critical road infrastructure: Loss of mission capability affecting national defense

- Foreign Object Damage (FOD): Pavement failure can lead to debris on the flight line. Jet engines can suffer major damage from even small objects being sucked into the engine

- Aircraft mooring and tie-down failure: Certain aircrafts such as Unmanned Aerial Vehicles (UAVs) require mooring and tie-downs embedded into the pavement. Corrosion-compromised embedment can jeopardize the hold-down capacity of these aircraft tie-downs

- Roads and related pavements: Inability to support design functions creating delays, congestion, and disruption

- Bridges: Access denial and risk of injury or death as a result of partial or complete collapse

- Waterfront-area pavements: Loss of mission capability, resupply capability, ship support and sustainment operations, and personal safety

The following impact corrosion performance of AC and PCC pavement:

- Environmental variables such as duration of exposure, temperature, and time of wetness

- Exposure to specific corrodents (salts, ultraviolet radiation, freeze-thaw cycle)

- System variables (quality of PCC mix and materials, AC composition and placement, integrity of subgrade and base course foundation materials)

- Construction processes (mix design, integrity and placement of reinforcing steel coating)

- Sustainment program and associated actions

- Functional effects such as loading (dynamic and dead weight) and vibration

- Construction oversight and management (material storage and management , quality assurance (QA), quality control (QC), and commissioning (Cx) programs)

Pavement-related corrosion stressors include:

- Thermal & photo oxidation

- Ultraviolet radiation degradation

- Freeze-thaw (frost heave)

- Corrosion of reinforcing steel

- Chemical impacts (salt and other chemicals)

- Heat impacts of jet blast (surface breakdown, spalling, exposure of reinforcing steel and associated foreign object damage (FOD) risk)

- Interaction of aircraft and vehicles with the pavement (friction loss, surface breakdown, over-weight vehicle traffic, etc.)

- Environmental Severity Classification variations (see Tables, UFC 1-200-01)

Corrosion impacts pavements in the following manner:

- AC binder breakdown and pavement hardening and embrittlement

- Loss of flexibility

- Cracking and pothole failure

- Base course and structural failure

- Spalling due to corrosion of steel in reinforced PCC

- PCC mix permeability and contaminants

- AC and PCC pavement surface failure

- Alkali-silica reaction

- For bridges: Corrosion of metals to include PCC reinforcing, structural steel, bridge deck corrosion and erosion, and metallic connectors. Note that the condition of the wearing surface on a bridge is affected by the steel and other materials that are influenced by humidity, rain, chloride-containing treatments and environment, structural loading, applied chemicals, and erosive forces

Description

Designers and constructors of pavements can increase system performance and longevity and reduce sustainment costs when the factors in the Introduction section are considered. Photo 1 shows a new AC runway which is the desired result of good design and construction. Keeping new pavements functional over the design service life is challenging. Both AC and PCC pavements depend heavily on the integrity of the subgrade and base. Leveraging the criteria highlighted in the Criteria Summary will result in good pavement designs. Those designs, accompanied by good-quality construction that meets contract requirements, supported by quality assurance (QA) and quality control (QC) programs, will result in longer-lasting facilities.

The handling and storage of construction materials significantly impacts whether the pavement infrastructure experiences corrosion. To mitigate this risk, constructors should ensure proper storage and handling of materials. Once corrosion protection mechanisms such as coatings or galvanizing break down initially, they continue to break down at a greater rate and the corrosion becomes more widespread. Even the most minuscule break in a reinforcing steel coating can be a starting point for corrosion, as shown in Photo 2. A marred or scratched surface becomes anodic to the surrounding metallic surface. Weldments can experience all the classical forms of corrosion such as galvanic, pitting, stress corrosion, inter-granular, and hydrogen cracking.

Photo 1: New runway

Source: MCAS Cherry Point, NC, LCPL Cory D. Polom

Photo 2: Coated reinforcing steel showing haphazard storage and damaged surfaces with surface corrosion (rust)

Source: Steve Geusic, P.E.

AC Pavements

While not every failure mode is corrosion-related, as previously stated, performance is an attribute of the entire system and the sum of the performance of components or individual items. One of the top ten costs of corrosion drivers from the Facilities and Infrastructure Corrosion Evaluation (FICE) Study includes AC pavement. The corrosion factors mentioned in the Vision Point Study for AC and PCC pavement are temperature, load-use, rainfall, ultraviolet (uV) exposure, and freeze-thaw cycles. Ultra-violet radiation caused degradation is the process by which organic-based polymers, used in the building and construction industry, undergo photolytic and photo-oxidative reactions during exposure to solar uV radiation. MDPI research (Hu, Wu, et al) (Multi-disciplinary Digital Publishing Institute (MDPI)) into the effects of oxidation and uV radiation indicate that these environmental factors result in brittleness, bitumen film reduction depth over time, as well as increased shrinkage stress in the AC binder surface leading to surface cracking and hardening of the pavement structure.

The following AC distress summary (from the Asphalt Institute) provides insights into the long-term system performance and associated corrective actions:

- Fatigue (Alligator Cracking)

- Block Cracking

- Edge Cracks

- Longitudinal (Linear) and Transverse Cracking

- Reflection Cracking

- Slippage Cracks

- Corrugations (Slippage) and Shoving

- Rutting

- Settlements and Grade Depressions

- Upheaval and Swell

- Utility Cuts and Patch Failure

- Pot Holes

- Raveling/Weathering

- Bleeding or Flushing

- Polished Aggregate

- Loss of Aggregate on Surface Treatments

- Longitudinal and Transverse Streaking

Photos 3 and 4 below provide a small sample of AC issues. The cost to repair or replace these pavement facilities can be substantial.

Photo 3: Fatigue, Alligator and Block Cracking, Raveling and Weathering, Reduction of AC Cover

Source: Guy Choate, GARVER USA.

Photo 4: Fatigue, Alligator and Block Cracking, Raveling and Weathering, Loss of Binder, Reduction of AC Cover

Source: Kelly White, 72nd Air Base Wing PAO.

Environment plays a large part in the degradation of asphalt pavements. Asphalt is greatly affected by uV exposure and temperature which ages and stiffens the binder. Stiffening of the asphalt binder leads to cracking and structural issues and can ultimately lead to the failure of the pavement. Effective protection of the asphalt surface from environmental corrosion can extend the design life of asphalt pavement. Surface treatments such as rejuvenators, micro resurfacing, and sealcoats are effective in reducing corrosion degradation from environmental and applied chemical stressors to extend the life of the pavement. Sealcoats can be applied directly after placement in new construction to mitigate post construction friction loss as well as reverse heat-related binder damage due to construction. Sealcoats can also be used to prevent corrosion due to fuel and Petroleum, oil, and lubricant (POL) spills caused by operations and maintenance activities. UFC 3-270-01 O&M Manual: Asphalt and Concrete Pavement Maintenance and Repair provides additional information on surface treatment options for AC pavements. UFC 3-250-03 Standard Practice Manual for Flexible Pavements emphasizes the importance of maintenance of AC pavements.

PCC Pavements

The quality of concrete and its ability to prevent corrosion is highly dependent on the quality of the mix design and construction activities associated with its placement and curing. Portland Cement Concrete (PCC) Pavement Distresses (UFC 3-270-01) include:

Cracking

- Corner break

- Divided slab

- Linear cracking

- Shrinkage cracking

- Spalling, corner

- Spalling, joint

Joint/crack related

- Faulting

- Joint/crack spalling

- Blowup/buckling

- Pumping

- Railroad crossing

Material related

- Alkali-silica reactivity (ASR)

- Durability ("D") cracking

Surface distress

- Polished aggregate

- Popouts

- Patching, large and utility cuts

- Patching, small

- Scaling

Miscellaneous distresses

- Lane/shoulder drop-off

The following factors improve the quality and longevity of PCC pavement:

- Integrity of the mix design

- Existence of supplementary cementitious materials (SCM) such as fly ash and other pozzolans. These materials are added to replace (15%–25%) of the cement and help to reduce the PCC permeability and as a result reduce the corrosion potential of the reinforcement

- Slump within design tolerances

- Refraining from adding water on site to improve workability (A lower water cement ratio usually results in stronger and less permeable PCC)

- Proper placement of reinforcement bars and tendons with the appropriate minimum PCC cover (see Photos 5 and 6)

- Consolidation of PCC, eliminating voids through proper vibration and placement techniques

- Controlling and minimizing PCC cracking and surface imperfections

- Proper joint design and construction

Excessive cracking and surface imperfections are usually the result of improper PCC placement, finishing, and curing. Environmental conditions and weather can affect PCC properties and finish. Publications by the American Concrete Institute and the Portland Cement Association as well as UFCs and UFGSs address quality control procedures for all aspects of PCC. Photos 5 and 6 show a PCC pavement construction project in progress.

Photos 5 and 6: Reinforcing Doweling Between Roadway Sections (Road Repair Work at Ft McCoy)

Source: Scott Sturkol, Ft McCoy PAO

Corrosion effects on PCC include:

- Alkali-silica reaction which occurs over time in PCC between the highly alkaline cement paste and the reactive non-crystalline (amorphous) silica found in many common aggregates. This reaction causes the expansion of the altered aggregate resulting in spalling and loss of strength of the PCC, finally leading to its failure (See Photo 7)

- Corrosion of reinforcing steel and doweling, especially between slab sections, and expansion joints. Steel dowels are used in PCC pavements to provide load transfer across joints. By nature of the joint, water and salt infiltration can cause localized corrosion of the dowels. The corrosion leads to the loss of dowel cross-section, which reduces the capability of the dowel to transfer loads and restrain vertical movement. The accumulation of corrosion products can restrict the free expansion and contraction of the slabs, causing joint lockup and inducing tensile cracks in the pavement.

- Corrosion of PCC pavement embedment such as airfield moorings and tie-downs

- POL spills and high heat applied by vertical engine blast from MV/CV-22 can cause a caustic chemical reaction which attacks the concrete surface (see Photos 8 and 9).

- Soils containing sulfates surrounding the pavement can penetrate the concrete and form detrimental minerals, similar to ASR reaction. The expansion of the concrete causes cracking which accelerates the reaction.

Photo 7: Alkali-Silica Reaction on a PCC Bridge Support

Photo Source: D, CPO

Photos 8 and 9: POL Spills and High Heat impacts MV/CV-22

Photo Source: NAVFAC Atlantic

Glass Fiber Reinforced Polymer Reinforcement

-

Glass Fiber Reinforced Polymer (GFRP) reinforcement consists of a polymeric material (polyester, vinyl ester, or epoxy) that is reinforced by glass fibers. Advantages of GFRP bars include corrosion resistance, high longitudinal strength, high fatigue endurance, and light weight. Disadvantages of GFRP bars include their high cost, low modulus of elasticity, and low shear strength.

-

Codes are being developed for non-prestressed GFRP-reinforced concrete used for structural purposes. These codes are not intended for pavements. GFRP-reinforced pavements were successfully used in continuously reinforced concrete pavement sections in Montreal (2006) and West Virginia (2007). However, technical challenges remain for widespread GFRP-reinforced pavements. For example, current GFRP reinforcement does not sufficiently resist transverse shear forces to allow its economic use in pavements—a larger cross-sectional area of GFRP may be required to provide the same shear strength as steel reinforcement. Furthermore, the small volume of steel reinforcement and limited benefit of any weight reduction make a less compelling business case for GFRP use in pavements.

- The combination of accepted codes for GFRP-reinforced structural concrete and improved GFRP materials or designs (e.g., alternative bar geometries or fiber orientations) will eventually lead to their use in pavements. At that time, GFRP-reinforced concrete pavements may be of value in locations with deicing salt use or with Environmental Severity Classification (ESC) of C4 or C5. GFRP reinforcement is also beneficial where electromagnetic transparency is desired. At the current time GFRP is not allowed for DoD pavements, further consideration will be made as codes are formalized and the technology evolves.

Criteria Summary

UFC 1-200-01 DoD Building Code, Chapter 4—Corrosion Prevention and Control, provides very specific guidance for design, construction and sustainment actions related to CPC. Tables A-2 and A-2, ESC for DoD Locations, identifies the Environmental Severity Classification (ESC) Zone for each of the DoD Installations around the world, which then drives the selection of the types of materials and processes that should be used for corrosion-prone locations.

The CPC highlights from several of the most relevant UFC and UFGS AC and PCC pavement related criteria include:

-

UFC 3-250-01 Pavement Design for Roads and Parking Areas provides pavement design procedures and requirements for the pavement design of roads and parking areas worldwide. It clarifies when state pavement design procedures may be used and when Pavement-Transportation Computer Assisted Structural Engineering (PCASE) is required. It addresses both AC and PCC pavement design to include soils, subgrade, base and reinforcing steel. It does not mention UV degradation or corrosion. It does mention alkali-silica reaction, spalling, and steel reinforcement uses and design.

-

UFC 3-250-03 Standard Practice Manual For Flexible Pavements discusses the importance of pavement maintenance actions, sealers, stabilization, and other useful information concerning mix design, materials, production, and placement of various AC mixtures.

-

UFC 3-250-04 Standard Practice for Concrete Pavements includes the August 1987 Army TM 5-822-7 and the Air Force AFM 88-6, Chapter 8, discusses the realities of the reaction of steel and de-icing salts and corrosion behavior when water is able to gain access. The use of coated dowels and reinforcing steel should be considered in the presence of seawater. Alkali-silica reactions as shown in Photo 8 are discussed in this UFC, which provides information on their risk, potential damage, and possible solutions. Much has transpired since this UFC was published, including extensive research into heat-resistant mix designs and the categorization and application of ESC Zones (see UFC 1-200-01).

-

UFC 3-260-01 Airfield and Heliport Planning and Design provides extensive detail on aviation facility design, including clearances. It does not address corrosion directly but contains content associated with vertical landing and takeoff as they relate to heat, surface deterioration and the creation of foreign object damage.

-

UFC 3-260-02 Pavement Design for Airfields provides an extensive description and discussion related to pavement joints and the associated need to establish and maintain joint integrity. Improper joint design and construction poses a serious risk factor related to CPC of pavements and the aircraft that utilize them. The UFC provides extensive guidance insights into pavement design, and while the word “corrosion” might not be used, the impact of failed subbase, water intrusion, erosion, and PCC cracking allows access to steel reinforcing that causes spalling and foreign object damage (FOD). In sandy soils, where drainage structures are installed under ramps and pavements, the erosion of the subbase into the drainage structure through pipe joints allows the pavements to crack and fail. The UFC also discusses alkali-silica aggregate reaction.

-

UFC 3-260-16 O&M Manual: Standard Practice For Airfield Pavement Condition Surveys discusses spalling, cracking, and foreign object damage (FOD) identification and severity. Both AC and PCC pavements are addressed and identified in a pictorial presentation. It does not address corrosion factors causing these conditions. The value, from a corrosion perspective, is in the understanding of the causative effects of corrosion on surface, edge and cracking.

-

UFC 3-270-01 O&M Manual: Asphalt and Concrete Pavement Maintenance and Repair discusses pavement distresses including cracking, rutting, raveling, or other types of surface deterioration which is indicative of the decline in the pavement’s structural load-carrying capacity. Asphalt Concrete (AC) Pavement Distresses are listed. Portland Cement Concrete (PCC) Pavement Distresses addresses the hazards of using gypsum-based PCC (calcium sulfate) repair materials and the presence of free sulfates in the promotion of corrosion in reinforcing steel in pavements. Crack sealing can become a corrosion and FOD problem if not executed properly. UFC 1-200-01 update requires application of new corrosion and related environmental severity guidance and was published after this UFC.

-

UFGS 03 30 00 Cast-in-Place Concrete covers the requirements for cast-in-place concrete not exposed to a marine or high-chloride environment. It addresses material restrictions to prevent alkali-silica reactions. It has extensive references to corrosion and associated material and admixture selections to prevent reinforcing steel deterioration, increase durability, and corrosion protection. It states requirements to store reinforcing materials to prevent damage that causes excessive rust. It addresses requirements for rust-proof aggregate. It discusses management of rust on reinforcing steel in detail and addresses the various reasons for cracking in the concrete along with associated limitations.

-

UFGS 03 31 29 Marine Concrete With Service Life Modeling covers requirements for reinforced concrete exposed to marine and chloride environments for projects with a defined service life, ESC classifications C4 and C5, and where deicing salts are used on the structure. Service modeling is described extensively. Corrosion topics are covered in depth on topics to include concrete qualification process and admixtures (corrosion inhibitors). The chloride threshold, corrosion initiation and propagation period, service life and service modeling (placing corrosion in context as a risk factor), and supplemental corrosion protection are addressed. The UFGS requires that deterioration mechanisms other than chloride induced be considered and mitigated. Rust and reinforcing steel are addressed. Cracking and spalling are also included. Note that this UFGS has extensive corrosion management requirements beyond this brief summary.

-

UFGS 03 31 30 Marine Concrete covers requirements for reinforced concrete exposed to marine and chloride environments for projects with no defined service life design, exposed to weather in ESC classifications C4 and C5, and where deicing salts are used on the structure. Note that UFC 1-200-01 contains the determination of ESC project locations and corrosion requirements. Corrosion topics are covered in depth on topics to include concrete qualification process and admixtures (corrosion inhibitors). Service life and supplemental corrosion protection including inhibitors are defined. Concrete quality control includes corrosion protection strategies, chemical deterioration, chemical inhibitors and supplemental corrosion protection references and requirements. Coatings and inhibitors are described in the context of “supplemental corrosion protection.” Corrosion requirements and reinforcing steel to include prestressing strands, reinforcing bars and supports are delineated. Rust and reinforcing steel are addressed. Shrinkage cracking is also included.

-

UFGS 32 01 13.63 Gilsonite Modified Asphalt Emulsion Seal Coats covers gilsonite modified asphalt surface coatings for roads, parking areas, airfields and other general applications with or without aggregate applied on the applied coating. The use of Gilsonite modified asphalt sealcoats prevents surface corrosion of asphalt pavements and should be used whenever possible. Sealcoats can be applied post construction and re-applied every three to four years.

-

UFGS 32 13 13.06 Portland Cement Concrete Pavement For Roads and Site Facilities covers requirements for PCC paving jobs such as roads, streets, sidewalks and parking lots. It mentions corrosion protection from moisture, freeze-thaw cycling and deicing salts. Reinforcing steel should be inspected to ensure that it is free of flaky rust. Shrinkage cracking is also included.

-

UFGS 32 13 13.43 High Temperature Concrete Paving For Airfields Using Lightweight and Traprock Aggregates is for concrete pavements exposed to temperatures of 482 degrees C (900 degrees F) or higher, referred to herein as High Temperature Concrete. Heat-resistant recommendations exist for concrete exposed to moderate temperatures of 149 to 482 degrees C (300 to 900 degrees Fahrenheit per Engineering Technical Letter (ETL) 14-2 but are also applicable to the specification. There is an extensive discussion about alkali-silica reaction, fly ash, and the associated designs concrete mix designs. Reinforcing steel should be inspected to ensure that it is free of flaky, thin powdery, and tight rust. Steel dowel requirements are addressed along with rust restrictions. Steel forms should be free of rust. Shrinkage cracking restrictions are defined.

-

UFGS 32 13 14.13 Concrete Paving for Airfields and Other Heavy Duty Pavements covers construction of concrete pavement for Army, Navy and Air Force airfields and heavy-duty roads, parking areas, hardstands, and vehicular traffic. The UFGS addresses alkali-silica reactivity aggregates, combinations of cementitious materials and concrete mix design. Reinforcing steel should be inspected to ensure that it is free of flaky, thin powdery, and tight rust. Steel dowel requirements are addressed along with rust restrictions. Steel forms should be free of rust. Shrinkage cracking restrictions are defined.

Sustainment

The understanding of pavement technology in the context of design, construction, and sustainment, along with the associated risks and stresses, is an absolute must for engineers, architects and sustainment engineers. Saltwater is an excellent electrolyte contributing to an aggressive corrosive environment with the associated impact on facilities. Hydrostatic forces, wind, salt spray, ultraviolet radiation, temperature variations, frost, heave, surface erosion, AC binder failure all contribute to corrosion and erosion of and PCC pavements. Utilizing sustainment management system (SMS) tools such AC as Paver™ , PCASE and Builder, will assist the installation in tracking pavement facilities and identifying maintenance requirements such that they can be quantified, funded, and sustained.

In general, preventive and predictive maintenance is more cost effective than corrective maintenance. Preventative corrosion maintenance can avoid or reduce the occurrence of:

- Emergency repair procedures

- Downtime and lost productivity

- Labor and material cost for component removal and replacement

- Shortened service life of the component

Methods of Corrosion Control for Pavements include:

- Utilizing an SMS tool such as Paver™ , PCASE

- Good design practice

- Material selection

- Good construction practice

- Good Quality Control and Quality Assurance focused on CPC in pavements

- Selection of appropriate surface treatments

- Corrosion awareness and facility monitoring

- Proactive sustainment management

- CPC Training

- QA, QC, and Cx

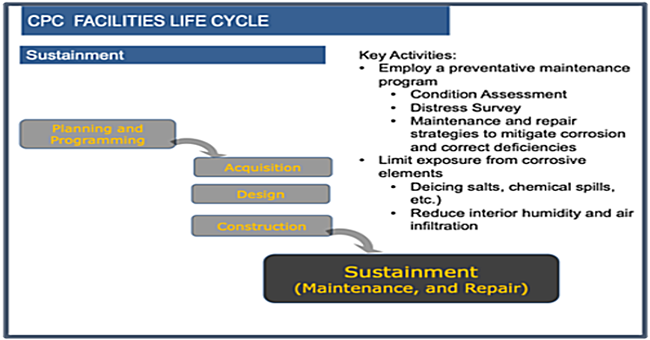

Figure 1, "CPC Facilities Life Cycle", illustrates the placement of preventive maintenance in the process. UFC 3-270-01 O&M Manual: Asphalt and Concrete Pavement Maintenance and Repair delineates types of maintenance and repair types to include:

-

Global Preventive Maintenance (PM) (Global PM is used to retard or slow pavement deterioration on a large scale, usually covering more than one section.)

-

Localized Preventive Maintenance (Localized PM consists of maintenance and repair (M&R) actions performed on individual distresses to slow down the rate of pavement deterioration.)

-

Operational Maintenance (Also referred to as safety maintenance, stop-gap maintenance, and breakdown maintenance, operational maintenance is performed to mitigate distresses on pavements that are below the critical pavement condition index (PCI) to keep them operationally safe for use.)

The UFC 3-270-01 also provides insights and guidance into the repairs of AC and PCC pavements with the associated chapter details. These sections are excellent starting points as sustainment professionals plan and develop repair programs. It is extremely important to leverage an accurate PM program. There are numerous types of M&R methods for AC and PCC pavements, which include patching, crack sealing, and surface treatments. Keeping an accurate asset database and an associated condition summary facilitates timely M&R actions that will keep the pavement in good operating condition and queued up for timely replacement.

Figure 1: CPC Facilities Life Cycle (Design Service Life)

Source: Steve Geusic, P.E.

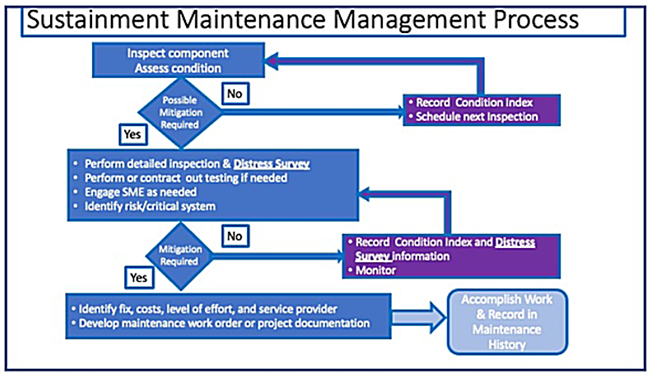

Figure 2 illustrates the Sustainment process and the associated work flow. Identifying and tracking pavement deficiencies through this process will ensure that the necessary work will be scheduled and accomplished in a timely process.

Figure 2: Sustainment Maintenance Management Process

Source: Steve Geusic, P.E.

The Ontario Hot Mix Producers Association has developed a good primer on The ABCs of Pavement Preservation with the message that planning understanding pavement management, planning ahead and doing the right thing will result in greater design service life effectiveness for AC pavements. Photos 10 through 14 provide examples of the challenges in the sustainment of pavements.

Photo 10: PCC Pavement Deterioration (55th CES, Travis Drive Repairs)

Source: Leticia Cunningham, 55th Wing Public Affairs Office

Photo 11: Harsh Winter Freeze Thaw Effects on PCC

Source: Concrete décor

Photos 12 and 13: AC Deterioration, Subgrade Failure, Pumping, Fatigue Cracking, Patching Failure, Loss of Binder and Polishing

Source: JCDEAN Indian Oaks Development

Photo 14: Potholing, Fatigue Cracking, Weathering and Loss of Aggregate on Surface Treatments UV Deterioration

Source: PavemanPro

Summary

Through understanding the severity and stresses associated with pavement design, construction, and sustainment, new and existing pavements will have a greater possibility of meeting mission requirements over the design service life. It is essential that the right materials are selected, installed and maintained. Pavements have to hold up to repetitive stresses and forces that can be marginalized by corrosion stressors. The engineer, architect and sustainment professional should seek assistance of subject matter experts (SMEs) in these areas as required to ensure that projects remain durable and sustainable over the desired design service life. The resources provided in this knowledge page are intended to assist in managing issues associated with AC and PCC pavements. Understanding how corrosion impacts AC and PCC pavements will improve designs, construction and sustainment.

Additional Resources

Department of Defense—Whole Building Design Guide

Unified Facilities Criteria (UFC)

- UFC 3-250-01 Pavement Design for Roads and Parking Areas

- UFC 3-250-04 Standard Practice For Concrete Pavements

- UFC 3-250-08FA Standard Practice For Sealing Joints and Cracks In Rigid and Flexible Pavements

- UFC 3-250-09FA Aggregate Surfaced Roads and Airfield Areas (Encloses Army TM 5-822-12, Design of Aggregate Surfaced Roads and Airfields, September 1990)

- UFC 3-260-01 Airfield and Heliport Planning and Design

- UFC 3-260-02 Pavement Design for Airfields

- UFC 3-260-03 Airfield Pavement Evaluation

- UFC 3-260-16 O&M Manual: Standard Practice for Airfield Pavement Condition Surveys

- UFC 3-270-01 O&M Manual: Asphalt and Concrete Pavement Maintenance and Repair

- UFC 3-270-08 Pavement Maintenance Management

Unified Facilities Guide Specifications (UFGS)

- UFGS 03 30 00 Cast-in-Place Concrete

- UFGS 03 31 29 Marine Concrete with Service Life Modeling

- UFGS 03 31 30 Marine Concrete

- UFGS 31 01 19.61 Sealing of Joints in Rigid Pavement

- UFGS 32 01 29.61 Partial Depth Patching of Rigid Paving

- UFGS 32 11 23 Aggregate Base Course

- UFGS 32 12 15.13 Asphalt Paving For Airfields

- UFGS 32 12 15.16 Stone Matrix Asphalt (SMA) for Airfield Paving

- UFGS 32 12 16 Hot-Mix Asphalt (HMA) For Roads

- UFGS 32 13 11 Concrete Pavement for Airfields and Other Heavy-Duty Pavements

- UFGS 32 13 13.06 Portland Cement Concrete Pavement for Roads and Site Facilities

- UFGS 32 13 13.43 High Temperature Concrete Paving For Airfields Using Lightweight And Traprock Aggregates

- UFGS 32 13 14.13 Concrete Paving for Airfields and Other Heavy Duty Pavements (Discusses alkali-silica reactivity aggregates, combinations of cementitious materials and concrete mix design)

WBDG Resources

- Corrosion Factors in DoD Facilities, Vision Point Systems, October 24, 2014

- Hangar Pavement Design

- Facilities and Infrastructure Corrosion Evaluation (FICE) Study (July 2013)

- CPC Source — Corrosion Science Knowledge Area

- CPC Source — Environmental Severity Classification (ESC)

- CPC Source — Facilities Corrosion Impacts on Operations and Mission

- CPC Source — Design and Construction Issues

- CPC Source — Corrosion Prevention And Control (CPC) In Operations And Maintenance (O&M), And, Sustainment, Restoration, Modernization (SRM)

- Aviation Hangar

- Aviation Facilities

U.S. Army Corps of Engineers

AFCEC—Air Force

Navy—NAVFAC

- Marianas Navy and Marine Corps Design and Construction Standards (MDACS) (September 2017)

- TDS NAVFAC EXWC-CI-1403 Mitigating Concrete Damage Caused by Engine Exhaust Surface Temperature Below 500 degrees Fahrenheit

Tri-Service Electrical Working Group (TSEWG) and Pavements/Airfields Working Group (TSPWG)

- TSPWG 3-250-07.07-6 Risk Assessment Procedure for Recycling Portland Cement Concrete (PCC) Suffering from Alkali-Silica Reaction (ASR) in Airfield Pavement Structures

- TSPWG 3-260-02.11-4 Airfield Pavement Drainage Layers

- TSPWG 3-270-08.14-03 Preventive Maintenance Plan (PMP) for Airfield Pavements

- TSPWG M 3-250-04.06-2 Alkali-Aggregate Reaction in Portland Cement Concrete (PCC) Airfield Pavements

- TSPWG M 3-260-02.07-3 Jet Engine Thrust Standoff for Airfield Asphalt Edge Pavements

- TSPWG M 3-270-01.3-270-07 O&M: Airfield Damage Repair

- TSPWG TSC 13-1 Inspector’s Manual for Hot-Mixed Asphalt and Portland Cement Concrete Pavement Construction

Tools

Training

- CPC Source — Training

- DoD Corrosion Related Training

DoD Installations Organizations

- Office of the Deputy Assistant Secretary of Defense (Construction)

- Engineer Research and Development Center, Construction Engineering Research Laboratory (ERDC-CERL)

- Air Force Civil Engineer Center (AFCEC)

- Naval Facilities Engineering and Expeditionary Warfare Center (NAVFAC EXWC)

Other Federal Government

Federal Aviation Administration

Federal Highway Administration

Publications and Standards

- 13 Pavement Defects and Failures You Should Know! by Brett Neal, Paveman Pro

- ACI 201.2R–08 Guide to Durable Concrete 2008

- ACI 222R–19 Guide to Protection of Metals in Concrete Against Corrosion

- ACI 222.3–11: Guide to Design and Construction Practices to Mitigate Corrosion of Reinforcement in Concrete Structures

- ACI CODE-440.11-22: Building Code Requirements for Structural Concrete Reinforced with Glass Fiber-Reinforced Polymer (GFRP) Bars-Code and Commentary

- ASTM C150/C150M Standard Specification for Portland Cement

- ASTM C618 Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete

- ASTM C260/C260M Standard Specification for Air-Entraining Admixtures for Concrete

- ASTM C494/C494M Standard Specification for Chemical Admixtures for Concrete

- ASTM C1017/C1017M Standard Specification for Chemical Admixtures for Use in Producing Flowing Concrete

- ASTM C173/C173M Standard Test Method for Air Content of Freshly Mixed Concrete by the Volumetric Method

- ASTM C1116/C1116M Standard Specification for Fiber-Reinforced Concrete

- ASTM D5893/D5893M Standard Specification for Cold-Applied, Single-Component, Chemically Curing Silicone Joint Sealant for Portland Cement Concrete Pavements

- ASTM A709/A709M Standard Specification for Structural Steel for Bridges

- "The Effect of Ultraviolet Radiation on Bitumen Aging Depth", MDPI.com, 7 May 2018, Junxuan Hu et al.

- The ABCs of Pavement Preservation, February 2004, Ontario Hot Mix Producers Association

Industry Organizations

- American Concrete Institute

- American Society of Civil Engineers (ASCE)

- Asphalt Institute

- Association for Materials Protection and Performance (AMPP)

- FHWA Resource Center — Pavement and Materials Team

- Multi-disciplinary Digital Publishing Institute (MDPI)

- National Research Council Canada

- Portland Cement Association

- Precast/Prestressed Concrete Institute