Overview

Within This Page

Animal research and animal research facilities are critical to the biomedical research enterprise. Animal species are used in every stage of the research and development effort-from discovery, to development and safety testing, to clinical trials, and to manufacture-because their biological systems, genetic structures, and immunological responses, in various ways, closely mirror ours as a species.

Numerous organizations have clearly articulated the importance and the value of animal research. Three of them are:

- Association for Accreditation and Assessment of Laboratory Animal Care International (AAALAC)

- New Jersey Association for Biomedical Research

- Pennsylvania Society for Biomedical Research

The animal research facility, also known as the vivarium, is a specially designed building type, which accommodates exquisitely controlled environments for the care and maintenance of experimental animals. Animal research facilities are related to but distinct from research laboratories. The facilities are complex, and expensive to build and to operate, but they are vital to the support of a proper, safe, and humane research effort.

Clients are pushing project design teams to create laboratories that are responsive to current and future needs; that encourage interaction among scientists from various disciplines; that help recruit and retain qualified scientists; and that facilitates partnerships and development. As such, a separate WBDG Resource Page on Trends in Lab Design has been developed to elaborate on this emerging model of laboratory design.

Building Attributes

Whether vivariums are embedded within a lab building, are in a separate structure connected to a lab building, or are independent free-standing structures, they share the same basic attributes.

Design Drivers

Walter Reed Army Institute of Research, Forest Glen, MD—A technically advanced, highly flexible facility which houses multiple organizations from the Army & Navy's major domestic biomedical research activities.

Photo Credit: HLW International LLP

-

Through the capabilities of their particular architecture and building systems, they maintain tight environmental control over the facility to avoid the introduction of contaminants or pathogens, and prevent the possibility of infectious outbreaks, and avoid the transmission of odors. See also WBDG High-Performance HVAC.

-

These facilities are fundamentally about the care and maintenance of the experimental animals.

-

Promote maintainability and cleanliness. See also WBDG Sustainable O&M Practices.

-

Organize circulation to permit controlled flows of people, animals, material, supplies, and wastes.

-

The ability of the operator to maintain and adapt environmental control within spaces and between circulation paths and to avoid contaminants or infection.

-

Cage sizing and cage systems are species-dependent and are governed by the standards set forth in the Guide for the Care and Use of Laboratory Animals. These in turn influence room sizes, room environment, and circulation patterns.

-

Research using animals is sensitive, and the design of these facilities requires a heightened awareness to the issues of security control to maintain confidentiality and to prevent unauthorized intrusions.

- The continuous maintenance of environments in these facilities must be without failure, downtime, or disruption. See also WBDG Productive—Assure Reliable Systems and Spaces.

Types of Spaces

-

Animal Housing Rooms (AHRs)—Accommodate caging, bedding change stations, and sinks. See Figures 1, 2, and 3 for examples. AHRs can be organized as individual rooms accessed from a corridor system or multiple rooms could be organized into self-contained suites.

Figure 1: Animal Housing Room for Rodents in Ventilated Racks View enlarged plan

Figure 2: Animal Housing Room for Non-human Primates View enlarged plan

Figure 3: Animal Housing Room for Dogs View enlarged plan

-

Procedure Rooms—Proximate to AHRs and frequently interchangeable with them; they are a primary setting for research activity within the unit. The method of allowing researcher access under controlled conditions is a critical issue to be solved.

-

Barrier Elements—Airlocks, lockers, pass-through autoclaves. These provide the primary barrier and access control that separates the controlled animal care environment from external influences.

-

Cagewash—The hub for all cleaning, sanitizing, and husbandry activities. These areas are dominated by equipment-generated heat and moisture. The major equipment items include pass-through rackwashers, tunnelwashers, pass-through autoclaves, bedding dispensers and dump stations, and bottle washing and filling stations.

-

Cage Storage—A necessary function, but a space consumer, which unfortunately is frequently short shrifted.

-

Storage—A necessary space and function for feed, bedding, and equipment has to be incorporated into the operational flow and space allocation.

-

Quarantine—Isolated AHRs for suspect and incoming animals that could be a source of infection.

-

Dedicated Receiving Dock—A dock specific to animal functions is generally required. An elevator dedicated to animal usage should be located near the dock.

-

Necropsy/Perfusion—Critical support function used for post mortem procedures on sacrificed animals. A "dirty" function that should not be proximate to "clean" areas.

-

Containment Facilities—Facilities for working with potentially infectious biological agents. They operate under negative pressure to prevent the escape of air to the general environment. Wastes and effluents are separately contained and decontaminated. Sophisticated control and monitoring systems and equipment are employed to achieve closely controlled and regulated air pressurizations and flows.

-

Barrier Facilities—Facilities for working with immuno-compromised species. These operate under positive pressure to keep contaminants out. As in containment facilities, control and monitoring systems and equipment are utilized in barrier facilities to maintain the required pressures and flows.

-

Veterinary Care—Lab and care functions, e.g. surgery, clinical chemistry, and histology.

-

Veterinary Office Space—Some provision for in-unit office spaces for veterinary care staff.

-

Staff Support Areas—Break area, cafeterias, workstation, lockers, and rest-room facilities. All are intended to support veterinary and research staff during their in-unit tours of duty.

-

Mechanical/Electrical Equipment Spaces—Mechanical equipment rooms, electrical and telecom closets, rooms for terminal trim devices such as dampers, coils, humidifiers and controls, distribution shafts, and mechanical penthouses. A desirable goal is to locate the spaces and devices in a manner that allows the separation of maintenance functions from animal care functions.

-

Corridors? tie everything together. These should be wide enough to accommodate animal rack, cart, and material traffic flow, not just egress requirements. Corridors should have a clear width of 7'–0" to 8'–0". Corridors should have impervious finishes so that they are easy to clean and maintain. Protective components such as bumper and corner guards are frequently employed to protect walls and doors from heavy, abusive traffic.

-

The general organization of a vivarium is illustrated in Figure 4.

Important Attributes

- Internal circulation systems need some form of control over clean vs. dirty (or supply vs. return) traffic.

- Cage wash is divided between a clean, that is an incoming or supply side, and a dirty, that is an outgoing or return side.

- Presumed or inherent, dirty functions such as necropsy and quarantine should be located near the dock.

- The Animal receiving areas should be subdivided to distinguished between incoming animals and receiving, and outgoing waste.

Architectural Design Elements

-

Floor-to-Floor Height—The clear height from floor to ceiling should be 8'–6" to 9'–0". The clear height above the ceiling should be 5'–0" to the underside of the structure to accommodate infrastructure support system distribution. Overall floor-to-floor height should be approximately 16'–0".

-

Floor and Framing System—Should be stable, monolithic, (preferably concrete), and capable of a 125 psf live load to dampen vibration. Epoxy terrazzo or resinous floor coatings are preferred.

-

Interior Walls and Partitions—Should be stable and capable of withstanding abuse and wash-down. Concrete masonry units are preferred substrate because of their strength and stability. There are many combinations of wall coatings, most of which employ block filler on CMUs for a smooth surface, trowelled on or sprayed on cement or epoxy based undercoatings, and are top coats with epoxy based products. Steel studs and moisture-resistant gypsum board can be used if necessary but should be coupled with protection, e.g., rails, bumpers, corner guards. Walls should have an impervious, easily cleanable finish, either block filler with latex paint, high-build coatings, or solid panels.

-

Doors—Should be a minimum of 42" wide and 84" high or more. Doors should be tall enough to accommodate the free movement of racks with integrated blowers. The opening size depends on the cage and rack system in use. The other key principle is that door assemblies should be constructed to prohibit the growth of vermin or bacteria. There are numerous system choices. What they should have in common is solidity, that is the absence of voids in the top and bottom rails of the door, the jambs and the strike; an easily cleanable and maintainable surface like epoxy painted steel, stainless steel, or fiberglass reinforced plastic (FRP); and surface that won't dent or dink. Doors need to be properly protected, particularly latches, locks, and other hardware. Continuous hinges are preferred.

-

Ceilings—Should consist of moisture-resistant gypsum board, latex paint or high-build coating, and sealant at intersections with walls and openings to ensure air and water tightness.

Mechanical Electrical Plumbing System Elements

-

Overall system design is largely governed by the Guide for the Care and Use of Laboratory Animals and ASHRAE Handbook—HVAC Applications, Chapters 16 and 24.

Example Building Automation System (BAS) that controls airflow and space temperature, and monitors system performance, etc. from a central location.

- HVAC is the dominant system (see also WBDG High-Performance HVAC):

-

It is the maintainer of environmental control via regulation of airflow, air cleanliness via filtration, temperature, humidity, odor transmission, and contaminant control.

-

Air changes per hour, a key benchmark of system capability, can vary from a minimum of 10 to greater than 20, which equates to 1.5 cfm/sf to more than 3 cfm/sf.

-

Air quality, caging type and caging density are the primary determinants of airflow rate.

-

Since HVAC is the life-sustaining system, consideration should be given to methods of providing redundancy and backup to maintain continual operation. See also WBDG Productive—Assure Reliable Systems and Spaces.

-

Building Automation Systems (BAS) via Direct Digital Controls (DDC) control and monitor the interaction of all elements of the HVAC system. BAS makes the HVAC system responsive and adaptive.

-

-

Plumbing systems are pervasive, but are varied, discrete, and independent. The most important elements are animal watering and major water users such as cage and rack washers. Watering system vendors maintain reliable empirical databases on watering needs by species. For major equipment, load capacity is calculated system by system.

-

Electrical systems are ubiquitous. The most critical issues are reliable power and redundancy and back-up for critical systems and equipment via standby generators, weather-protected outlets in wet locations, and the increasing use of computers in procedure and holding rooms. Other critical electrical systems include: lighting cycle control, security, and monitoring of water usage.

Construction Costs

-

In the New York City metropolitan area, new animal research facility construction in 2005 costs $425 — $475/sf, renovations cost $325 — $375/sf. Nationwide costs are generally 85% — 95% of the NY metro costs, depending on local market conditions.

-

MEP systems represent 45% — 50% of the total construction cost.

Emerging Issues

- New research directions and technologies have increased the use of new experimental species:

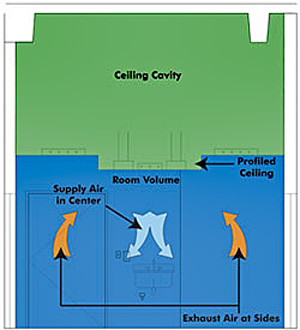

- Transgenic mice are widely used in genomic-based research across all therapeutic areas. This has been increasing the use of higher density housing types of caging in order to run more studies in shorter time periods, thus to generate a higher level of throughput. The impact on facilities has been to alter room design and room airflow characteristics to accommodate the new high density ventilated racks.

- Zebra fish are extensively used in neuroscience studies.

- New caging and housing types, such as high density ventilated racks (HDVRs), have altered room design and are promoting the increased usage of computational fluid dynamics (CFDs) to model room environments and HVAC characteristics. When given input on room footprint, volume, lighting, air output, and heat loads sources, CFDs can generate hitherto never before conceived optimized space configurations.

-

Automated record-keeping and integration with Building Automation Systems.

-

Initiatives to promote psychological well-being of animals are affecting all species. Providing for such natural behaviors as exercise, opportunities for group interactions, and nesting and foraging are warranting new ideas to replace more stressful traditional housing paradigms.

-

Labor saving technologies such as robotics and to a lesser extent, overhead gantry- or floor rail-based-systems, are being more extensively applied in cagewash facilities.

-

Reliance on the institutional knowledge of veterinary staff at all levels during the design process is increasing.

-

A "zoning" approach to facility layout that allows access to daylight via windows or other means at office and non-sensitive support spaces without having the staff leave the animal environment. This approach also provides for maintenance and device access zones for non-vivarium operational staff to service the vivarium MEP systems without crossing the animal environment barrier.

-

Designing the AHR space as a flexibly-rearranged entity which can be readily changed between animal holding and procedural functions with a minimum of refit as study paradigms change.

- The streamlining of waste treatment and disposal in an environmentally-sensitive manner, both from the cagewashing operation and Necropsy/Perfusion spaces, are being addressed with new technologies.

Relevant Codes and Standards

- ASHRAE Handbook—HVAC Applications, Chapter 16 Laboratories

- ARS Facilities Design Standards Manual ARS 242.1M by U.S. Department of Agriculture, Research Education and Economics. (See Chapter 9.4 for BL3 and BL3 Ag facility design standards. See Chap. 9.6 for Testing and Certification requirements.)

- Biosafety in Microbiological and Biomedical Laboratories (BMBL) 5th Edition by U.S. Department of Health and Human Services, Centers for Disease Control and Prevention and National Institutes of Health

- Guide for the Care and Use of Laboratory Animals by the Institute of Laboratory Animal Resources, Commission on Life Sciences, National Research Council

Government Agencies

- USDA Animal and Plant Health Inspection Service (APHIS)—APHIS is responsible for vivarium facilities under the U.S. Code of Federal Regulations.

Additional Resources

Associations/Organizations

- American Association for Laboratory Animal Science (AALAS)

- Association for Assessment and Accreditation of Laboratory Animal Care (AAALAC)—AAALAC is the most globally oriented and most widely known organization of animal research professionals. It promotes the humane treatment of animals in science through a voluntary accreditation program.

- Institute for Laboratory Animal Research (ILAR)

- Scientific Equipment and Furniture Association (SEFA)

Publications

- Building Type Basics for Research Laboratories, 2nd Edition by Daniel Watch. New York: John Wiley & Sons, Inc., 2008. ISBN# 978-0-470-16333-7.

- Guide for the Care and Use of Laboratory Animals by the Institute of Laboratory Animal Resources, Commission on Life Sciences, National Research Council. National Academy Press, Washington, D.C. 1996.

- ILAR Journal—The quarterly, peer-reviewed publication of the Institute for Laboratory Animal Research.